Page 26

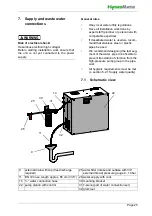

7.2 Water inlet

For the supply water feed, a connection piece

with a ¾

“ external thread is located on the

left unit housing wall.

Mount waterfilter close to pump station fol-

lowing these steps:

»

Transfer mounting bracket hole pat-

tern to a suitable location on wall.

»

drill holes, dowel and attach moun-

ting bracket with the mounting mate-

rial included with the water filter.

»

Screw T-piece included in water

connection set to water filter outlet

and affix pressure gauge.

»

Connect open T-piece outlet with

pump station using the water

connection hose supplied.

»

Connect the external feed water line

to the input side of the water filter

(¾ “ external thread).

The screws supplied are designed for mount-

ing on a concrete wall/floor. Should you find

other local conditions, please use appropri-

ately adapted mounting material.

7.2.1 Supply water quality

The supply water for the high-pressure noz-

zle system must comply with VDI 6022; i.e.

from a microbiological point of view it must be

of drinking water quality.

A flameresistant sampling tap

is to be pro-

vided on-site in the direct vicinity of the

HygroMatik high-pressure nozzle system.

Conductivity:

5...50 µS/cm

Pressure:

0.1...0.5 MPa (1...5 bar)

Volume flow:

greater than the max. transpo-

ration capacity of the high-pressure nozzle

system

Temperature:

5...15 °C

pH value:

7 +/-1

7.3 Water drain

On the left side of the unit housing a DN12

plastic hose is fed out. The water drain is

used for:

•

emptying and relieving the high-pres-

sure lines to the vortex module wall

after the enabling signal has been

removed

•

draining the flushing water from the

feed water line in a flushing process

Design of the water drain

The DN12 water drain hose must show a

constant decline towards the drain, must

include a siphon and allow for free draining.

NOTICE

Please note