Page 31

10. Commisioning

The description following hereafter is a short

instruction for the commissioning of the high-

pressure nozzle system.

In this form, it is primarily ment for recommis-

sioning after decommissioning of the system.

For

initial

start-up

of the unit by the com-

pany in charge for the installation of the noz-

zle system, a much more detailed document

is available with the title „Installation and ini-

tial operation instructions for HygroMatik adi-

abatic humidification systems“.

Improper installation hazard!

Start-up of the high-pressure nozzle system

is restricted to HygroMatik staff or authorized

personnel only.

Risk of electrical shock!

Hazardous electrical voltage!

Follow safety instructions for work on live

components.

Commissioning steps

Prior to

Initial start-up

, the prerequisites

required on-site must be met. Pls., confirm by

the notification of readiness form attached at

the end of the section (sent by fax or e-mail)

that this is the case.

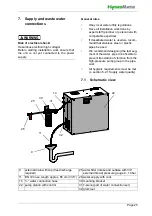

Step 1: Check wiring and hose connec-

tions

»

Check that all electrical wire connec-

tions are tight and secure.

»

Check hose connections for secure

clamping and safe connections.

Step 2: Switch-on the high-pressure noz-

zle system

»

Switch on main breaker.

»

Open water supply stop cock.

»

Switch on unit by setting control

switch to “I”.

»

close safety (interlock) system

Step 3:

The unit performs a self-test and,

then, commences normal operation

•

During self-test, the On/Off button icon

flashes for a couple of seconds

•

On completion of the test, the commis-

sioning screen is shown in the display

for the basic unit settings (such as lan-

guage, time and date, type of control

signal and type of control). On this

screen the respective settings must be

made except when the settings have

been made ex factory according to the

order options ( for parameter setting, s.

section 12.2 „Screen 1 - Initial opera-

tion“ in the „Operation of control“ chap-

ter).

•

Consequently, normal operation is

commenced. However, humidification

or cooling is not started without a

demand pending

Step 4: Trigger demand

»

Set control to 1-step operation, i.e.

permanent demand in the corre-

sponding parameter in the display.

»

Close safety (interlock) system.

»

Place bridge or switch between ter-

minals 3 and 5 (main board).

•

The high-pressure pump starts opera-

tion and transfers water to the nozzles

with a pressure of up to 75 bar.

•

Water is atomized by the nozzles.

WARNING

!

WARNING

!