ENGINE 3-18

Remove the gearshift fork shaft

and gearshift fork

.

Remove the gearshift cam

.

Remove the driveshaft assembly

, countershaft

assembly

.

Remove the oil pump idle gearshaft

.

Remove the crankshaft by using the special tool.

Crankcase separator : 09920-13120

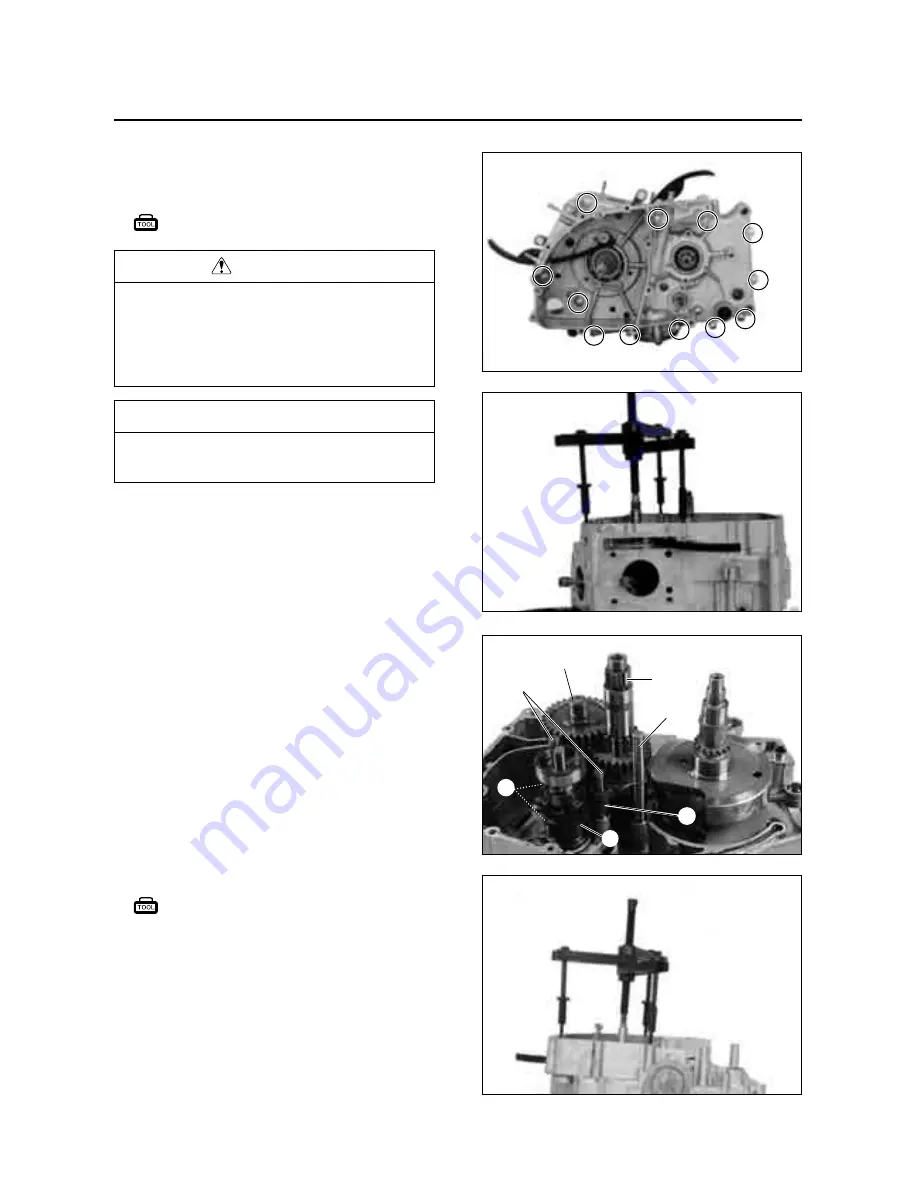

Remove the crankcase securing bolts.

Separate the crankcase into 2 parts, right and left,

with a special tool.

Crankcase separator : 09920-13120

CAUTION

When separating the crankcase , necessarily,

remove it after installed the special tool (Crankcase

separator) on the side of clutch.

In case separate oppositely, the gearshift cam stop-

per will be damaged in the side of magneto.

NOTE

Fit the crankcase separater, so that the tool

arms parallel the side of the crankcase.

Summary of Contents for 2002 Comet 125

Page 1: ...SERVICE MANUAL 99000 94710 SERVICE MANUAL HYOSUNG MOTORS MACHINERY INC ...

Page 5: ...NOTE Difference between photographs and actual motorcycles depends on the markets ...

Page 13: ...EXTERIOR ILLUSTRATION 1 7 GENERAL INFORMATION ...

Page 96: ...CARBURETOR FUEL SYSTEM 4 4 ...

Page 118: ...LAMP HEADLAMP TURN SIGNAL LAMP TAIL BRAKE LAMP Front Rear ELECTRICAL SYSTEM 5 16 ...

Page 138: ...FRONT FORK CHASSIS 6 14 ...

Page 144: ...FRONT FORK CHASSIS 6 20 ...