[

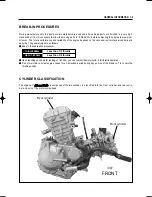

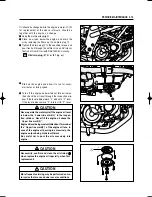

REAR CYLINDER

]

[

FRONT CYLINDER

]

MAINTENANCE PROCEDURES

This section describes the service procedure for

each section of the periodic maintenance.

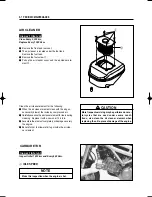

VALVE CLEARANCE

The valve clearance specification is different for

intake and exhaust valves.

Valve clearance adjustment must be checked and

adjusted,

1) at the time of periodic inspection,

2) w h e n t h e v a l v e m e c h a n i s m i s s e r v i c e d , a n d

3 ) when the camshaft is disturbed by removing it

for servicing.

●

Remove the spark plug. (Refer to page 2-5)

●

Remove the fuel tank. (Refer to page 4-1)

●

Remove the radiator. (Refer to page 5-2)

●

Remove the cylinder head cover bolt

①

and

②

.

●

Remove the magneto cover plug

③

and the tim-

ing inspection plug

④

.

0.1

�

0.2 mm (0.004 ~ 0.008 in)

0.2

�

0.3 mm (0.008 ~ 0.012 in)

IN.

EX.

Standard (When cold)

Valve clearance

Thickness gauge : 09900-20806

●

Rotate the magneto rotor counter-clockwise to set

the front cylinder

’

s piston at TDC (Top Dead

Center) of the compression stroke.

(Rotate the rotor until

“

|

F

”

line on the rotor is aligned

with the center of hole on the crankcase.)

●

To inspect the front cylinder

’

s valve clearance, insert

the thickness gauge to the clearance between the

camshaft and the tappet.

Inspect Interval

Inspect Initial 1,000 km and Every 6,000 km.

CAUTION

The clearance specification is for COLD state.

2-3 PERIODIC MAINTENANCE

②

①

③

④

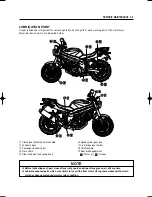

Summary of Contents for GT 650

Page 5: ...NOTE Difference between photographs and actual motorcycles depends on the markets ...

Page 13: ...1 7 GENERAL INFORMATION EXTERIOR ILLUSTRATION ...

Page 102: ...CARBURETOR 4 3 FUEL SYSTEM ...

Page 138: ...LAMP HEADLAMP TURN SIGNAL LAMP TAIL BRAKE LAMP ELECTRICAL SYSTEM 6 16 ...

Page 158: ...7 15 CHASSIS FRONT FORK ...