3-29

ENGINE

LOWER END COMPONENTS

INSPECTION AND SERVICING

CONROD SMALL END INSIDE DIAM-

ETER INSPECTION

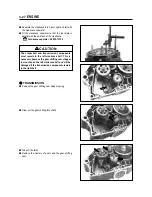

Using a dial calipers, measure the conrod small end

inside diameter both in vertical and horizontal directions.

If any of the measurements exceeds the service limit,

replace the conrod.

CONROD DEFLECTION INSPECTION

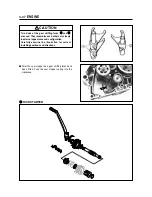

Move the small end sideways while holding the big end

immovable in thrust direction.

Measure the amount of deflection.

Turn the conrod and see if it moves smoothly without

play and noise.

This method can check the extent of wear on the parts

of the conrod s big end.

CONROD BIG END SIDE CLEAR-

ANCE INSPECTION

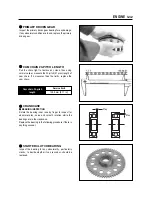

Using a thickness gauge, measure the side clearance at

the conrod big end. If the measurement is out of stan-

dard value, measure the conrod big end and the crank

pin widths individually to determine which one is to be

replaced.

CRANKSHAFT RUNOUT INSPEC-

TION

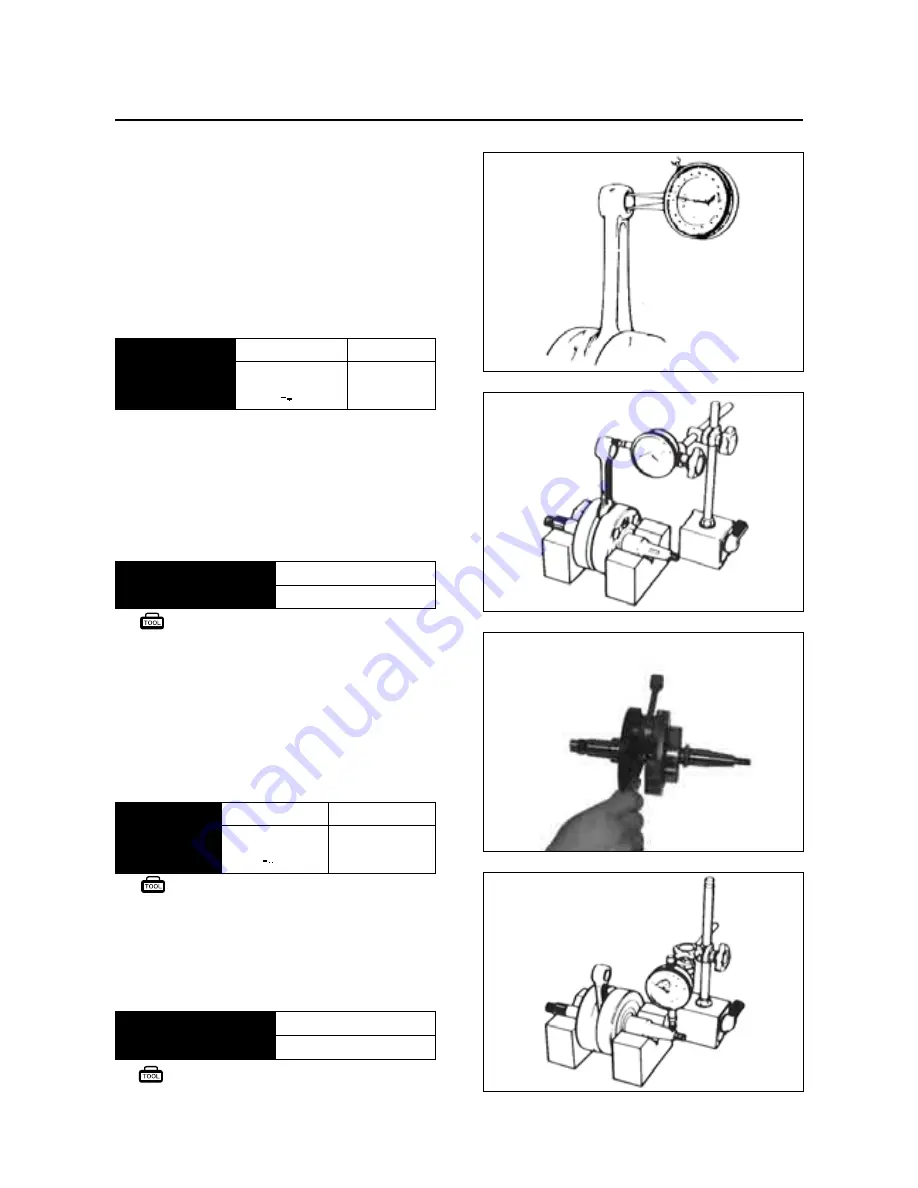

With the right and left crank journals supported with V-

block, turn the crankshaft slowly. At this time, measure

the crankshaft end runout using a dial gauge. If the

runout exceeds the service limit, replace the crankshaft.

Standard

15.006~15.014 mm

(0.5908 0.5911 in)

Service limit

15.040 mm

(0.5921 in)

Conrod small end

inside diameter

Service limit

0.05 mm (0.002 in)

Crankshaft runout

Magnetic stand : 09900-20701

Dial gauge : 09900-20606

V-block : 09900-21304

Service limit

3.0mm (0.12 in)

Conrod deflection

Magnetic stand : 09900-20701

Dial gauge : 09900-20606

V-block : 09900-21304

Standard

0.10~0.45 mm

(0.004 0.018 in)

Service limit

1.0 mm

(0.04 in)

Conrod big end

side clearance

Thickness gauge : 09900-20806