3-27 ENGINE

Service limit

0.180 mm (0.007 in)

0.150 mm (0.006 in)

Piston ring-groove clearance

1st

2nd

▣

▣

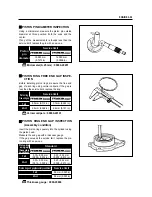

PISTON RING-TO-GROOVE CLEAR-

ANCE INSPECTION

Remove carbon deposit both from the piston ring and

its groove.

Fit the piston ring into the groove. With the ring com-

pressed and lifted up, measure the clearance on the

bottom side of the ring using a thickness gauge.

If any clearance reading exceeds the service limt,

replace both the piston and piston rings.

Standard

Standard

Piston ring thickness

Standard

Piston ring groove width

Oil

2nd

1st

2.01 ~ 2.03 mm

(0.079 ~ 0.080 in)

1.01 ~ 1.03 mm

(0.040 ~ 0.041 in)

1.01 ~ 1.03 mm

(0.040 ~ 0.041 in)

2nd

1st

0.970 ~ 0.990 mm

(0.0382 ~ 0.0390 in)

0.970 ~ 0.990 mm

(0.0382 ~ 0.0390 in)

Micrometer(0~25 mm) : 09900-20201

Thickness gauge : 09900-20806

Summary of Contents for MS3 125

Page 6: ...NOTE Difference between photographs and actual motorcycles depends on the markets ...

Page 134: ...5 1 FUEL SYSTEM AND THROTTLE BODY FUEL SYSTEM ...

Page 139: ...FUEL SYSTEM AND THROTTLE BODY 5 6 THROTTLE BODY ...

Page 249: ...9 31 SERVICING INFORMATION WIRE AND CABLE ROUTING ...

Page 250: ...SERVICING INFORMATION 9 32 ...

Page 251: ...9 33 SERVICING INFORMATION ...

Page 252: ...SERVICING INFORMATION 9 34 ...

Page 253: ...9 35 SERVICING INFORMATION WIRING DIAGRAM ...

Page 254: ...SERVICING INFORMATION 9 36 ...

Page 257: ...Prepared by 1st Ed DEC 2007 Manual No 99000HP8810 Printed in Korea ...