3-29 ENGINE

▣

▣

CONROD BIG END SIDE CLEARANCE

INSPECTION

Push the big end of the conrod to one side and mea-

sure the side clearance using a thickness gauge.

If the clearance exceeds the service limit, replace the

crankshaft assembly with a new one or bring the

deflection and the side clearance within the service

limit by replacing the worn parts (conrod, big end

bearing, crankshaft, crank pin, etc.) with new ones.

Standard

0.10 ~ 0.45 mm

(0.004 ~ 0.018 in)

1.0 mm

(0.040 in)

Service limit

Conrod big

end side

clearance

CRANKSHAFT

▣

▣

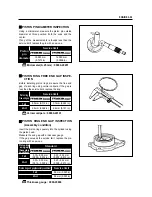

CRANKSHAFT RUNOUT INSPECTION

With the right and left crank journals supported using

a V-block, turn the crankshaft slowly. At this time,

measure the crankshaft end runout using a dial

gauge. If the runout exceeds the service limit,

replace the crankshaft with a new one.

Crankshaft runout

0.01 mm (0.0004 in)

Service limit

Crankshaft runout

0.03 mm (0.0012 in)

Service limit

Thickness gauge : 09900-20806

Dial gauge : 09900-20606

Magnetic stand : 09900-20701

V-block : 09900-21304

Summary of Contents for MS3 125

Page 6: ...NOTE Difference between photographs and actual motorcycles depends on the markets ...

Page 134: ...5 1 FUEL SYSTEM AND THROTTLE BODY FUEL SYSTEM ...

Page 139: ...FUEL SYSTEM AND THROTTLE BODY 5 6 THROTTLE BODY ...

Page 249: ...9 31 SERVICING INFORMATION WIRE AND CABLE ROUTING ...

Page 250: ...SERVICING INFORMATION 9 32 ...

Page 251: ...9 33 SERVICING INFORMATION ...

Page 252: ...SERVICING INFORMATION 9 34 ...

Page 253: ...9 35 SERVICING INFORMATION WIRING DIAGRAM ...

Page 254: ...SERVICING INFORMATION 9 36 ...

Page 257: ...Prepared by 1st Ed DEC 2007 Manual No 99000HP8810 Printed in Korea ...