HT2000

Instruction Manual

6-15

OPERATION

13

Mild Steel

200 amps • O

2

Plasma / Air Shield

This gas combination gives superior cut speed, minimum dross, minimum surface nitriding and excellent

weldability.

Shield

Arc

Approx.

Material

Plasma Gas Flow Rate %

Gas (Air)

Torch-to-work

Initial Torch

Voltage

Motion

Thickness

Preflow

Cutflow

Pressure

Distance

Piercing Height

Setting

Travel Speed

Delay Time

(inches)

(mm)

(O

2

% N

2

%) (O

2

% N

2

%)

(psi)

(inches)

(mm)

(inches)

(mm)

(volts)

(ipm) (mm/min.)

(sec)

Shield

Arc

Approx.

Material

Plasma Gas Flow Rate %

Gas (Air)

Torch-to-work

Initial Torch

Voltage

Motion

Thickness

Preflow

Cutflow

Pressure

Distance

Piercing Height

Setting

Travel Speed

Delay Time

(inches)

(mm)

(O

2

% N

2

%) (O

2

% N

2

%)

(psi)

(inches)

(mm)

(inches)

(mm)

(volts)

(ipm) (mm/min.)

(sec)

1/4

6

5

45

64

0

60

1/8

3

1/4

6

120

160

4060

0.5

.315

8

(5.3 / 62.4 (79.6 / 0

(270

1/8

3

1/4

6

125

120

3000

0.5

3/8

10

SCFH)

SCFH)

SCFH)

1/8

3

1/4

6

125

100

2540

1.0

1/2

12

.157

4

.314

8

125

80

2030

2.0

5/8

15

.157

4

.314

8

130

70

1780

2.0

3/4

20

3/16

5

3/8

10

135

55

1400

2.5

7/8

22

1/4

6

1/2

12

135

45

1140

2.5

1

25

1/4

6

1/2

12

140

35

890

2.5

1 1/4

32

1/4

6

150

22

560

1-1/2

38

1/4

6

155

15

380

1-3/4

44

5/16

8

165

10

250

2

50

5/16

8

170

7

180

Notes:

Set oxygen plasma gas inlet pressure to 120 psi (8.3 bar).

Set nitrogen plasma gas inlet pressure to 120 psi (8.3 bar)

Set shield gas inlet pressure to 90 psi (6.2 bar)

Production cutting above 1" (25 mm) not recommended. Drop cutting above 1-1/2" (38 mm) not recommended

* Use 020679 swirl ring in place of 120833 swirl ring to obtain smoother cut edges on material

1/4" to 3/8" thick, but expect a 30-40% decrease in electrode life

+ SilverPlus provides increased life to high duty cycle users in most applications. The hafnium wears to

approximately twice the depth of an all copper electrode (120667). Arc voltage may need to be increased by

5-10 volts throughout the electrode life to maintain proper cut height parameters.

Above Water

1/4

6

5

45

64

0

70

1/8

3

1/4

6

125

145

3700

0.5

.315

8

(5.3 / 62.4 (79.6 / 0

(270

1/8

3

1/4

6

125

110

2800

0.5

3/8

10

SCFH)

SCFH)

SCFH)

1/8

3

1/4

6

130

80

2000

1.0

1/2

12

1/8

3

1/4

6

130

70

1800

2.0

5/8

15

.157

4

.314

8

135

60

1500

2.0

3/4

20

3/16

5

3/8

10

140

48

1200

2.5

7/8

22

1/4

6

1/2

12

140

38

950

3.0

1

25

1/4

6

1/2

12

145

25

680

3.0

3" Under Water

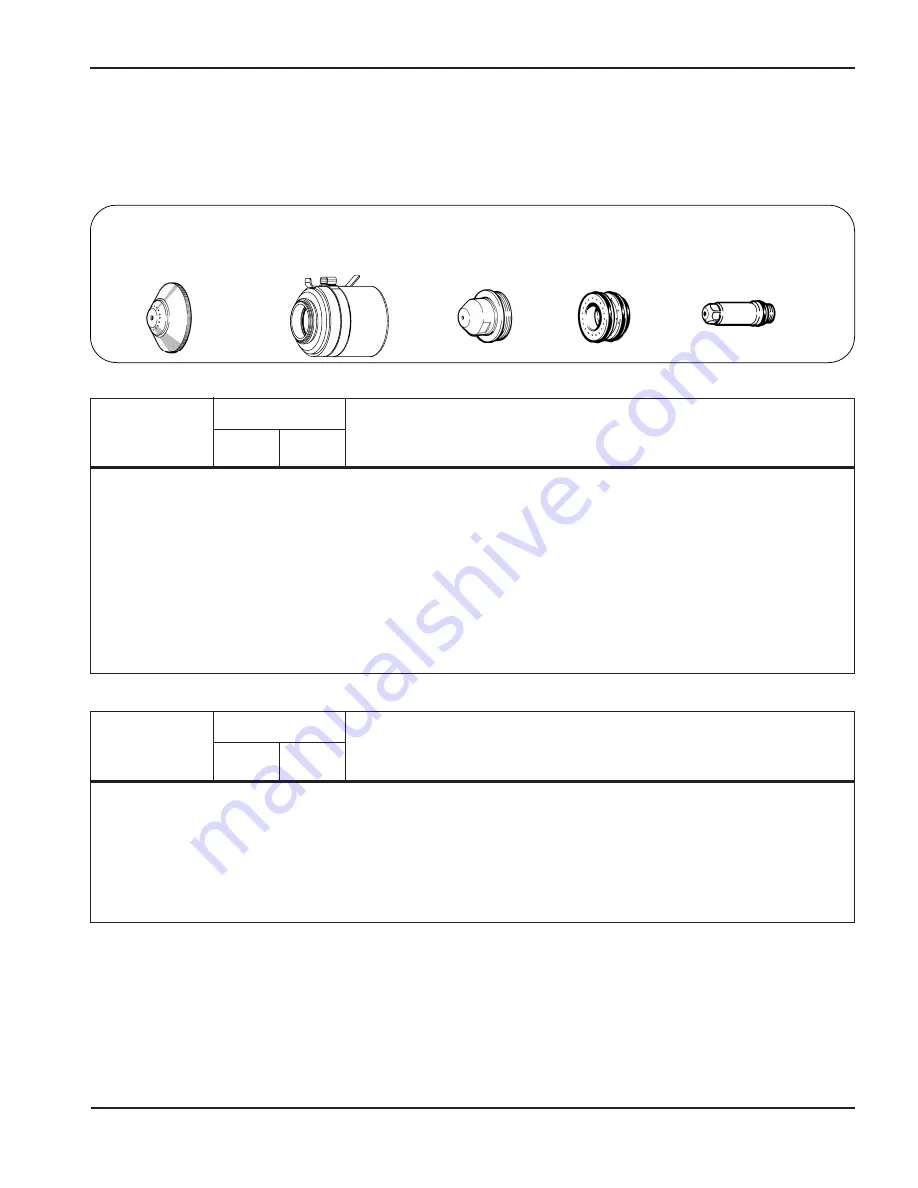

120833*

(cw)

120834

(ccw)

Swirl ring

120667 (standard)

Electrode

220084 (optional)

SilverPlus electrode

+

020605

Nozzle

120837

(cw)

120838

(ccw)

Retaining cap

020424

Shield

Summary of Contents for HT2000

Page 1: ...200 Volt Plasma Arc Cutting System Instruction Manual 802460 Revision 14 HySpeed HT2000 ...

Page 9: ......

Page 95: ...POST INSTALLATION 5 8 HySpeed HT2000 Instruction Manual 19 ...

Page 175: ...MAINTENANCE 8 30 HySpeed HT2000 Instruction Manual 22 ...

Page 235: ......

Page 236: ......

Page 237: ......

Page 238: ......

Page 239: ......

Page 240: ......

Page 241: ......

Page 242: ......

Page 243: ......

Page 244: ......

Page 245: ......

Page 246: ......

Page 247: ......

Page 248: ......

Page 249: ......

Page 250: ......

Page 251: ......

Page 252: ......

Page 253: ......

Page 254: ......

Page 255: ......

Page 257: ......

Page 259: ......

Page 261: ......

Page 262: ...Coolant Flow Diagram ...

Page 263: ......

Page 265: ...APPENDIX A a 2 HySpeed HT2000 Instruction Manual 20 ...

Page 267: ...b 2 HySpeed HT2000 Instruction Manual 19 ...

Page 268: ...HySpeed HT2000 Instruction Manual b 3 19 ...

Page 269: ...b 4 HySpeed HT2000 Instruction Manual 19 ...

Page 270: ...HySpeed HT2000 Instruction Manual b 5 19 ...

Page 272: ...HySpeed HT2000 Instruction Manual b 7 19 ...

Page 273: ...b 8 HySpeed HT2000 Instruction Manual 19 ...

Page 274: ...HySpeed HT2000 Instruction Manual b 9 19 ...

Page 275: ...b 10 HySpeed HT2000 Instruction Manual 19 ...

Page 279: ...APPENDIX D d 2 HySpeed HT2000 Instruction Manual 19 ...

Page 285: ...APPENDIX E e 6 HySpeed HT2000 Instruction Manual 19 ...