OPERATION

4-16

HySpeed HT2000LHF

Instruction Manual

7

Shield

Arc

Approx.

Material

Plasma Gas Flow Rate %

Gas (Air)

Torch-to-work

Initial Torch

Voltage

Motion

Thickness

Preflow

Cutflow

Pressure

Distance

Piercing Height

Setting

Travel Speed

Delay Time

(inches)

(mm)

(Air %)

(Air %)

(psi)

(inches)

(mm)

(inches)

(mm)

(volts)

(ipm) (mm/min.)

(sec)

Shield

Arc

Approx.

Material

Plasma Gas Flow Rate %

Gas (Air)

Torch-to-work

Initial Torch

Voltage

Motion

Thickness

Preflow

Cutflow

Pressure

Distance

Piercing Height

Setting

Travel Speed

Delay Time

(inches)

(mm)

(Air %)

(Air %)

(psi)

(inches)

(mm)

(inches)

(mm)

(volts)

(ipm) (mm/min.)

(sec)

.075*

2

48

39

60

3/32

2.5

3/16

5

120

235

6050

1/8

3

(55.3

(44.9

(270

3/32

2.5

3/16

5

125

185

4700

0.5

3/16

5

SCFH)

SCFH)

SCFH)

1/8

3

1/4

6

125

175

4450

0.5

1/4

6

1/8

3

1/4

6

130

125

3175

0.5

3/8

10

1/8

3

1/4

6

135

50

1270

1.0

1/2

12

1/8

3

140

35

890

5/8

15

.157

4

145

25

635

3/4

20

3/16

5

150

20

510

Mild Steel

100* amps • Air Plasma / Air Shield

This gas combination gives good cut speed, low dross levels and is very economical. Some surface nitriding can

occur. While this process may be used on thicker materials, optimal recommended range is to 3/8" (10mm).

*

Set arc current to

80 amps

when cutting .075" (2 mm) thick mild steel

Notes:

Set plasma gas inlet pressure to 90 psi (6.2 bar)

Set shield gas inlet pressure to 90 psi (6.2 bar)

Production cutting above 3/8" (10 mm) not recommended

Above Water

1/8

3

48

39

70

5/64

2

5/32

4

130

120

3050

3/16

5

(55.3

(44.9

(270

1/8

3

1/4

6

135

90

2300

0.5

1/4

6

SCFH)

SCFH)

SCFH)

1/8

3

1/4

6

140

70

1730

0.5

3/8

10

1/8

3

1/4

6

145

42

1050

0.5

1/2

12

1/8

145

28

700

3" Under Water

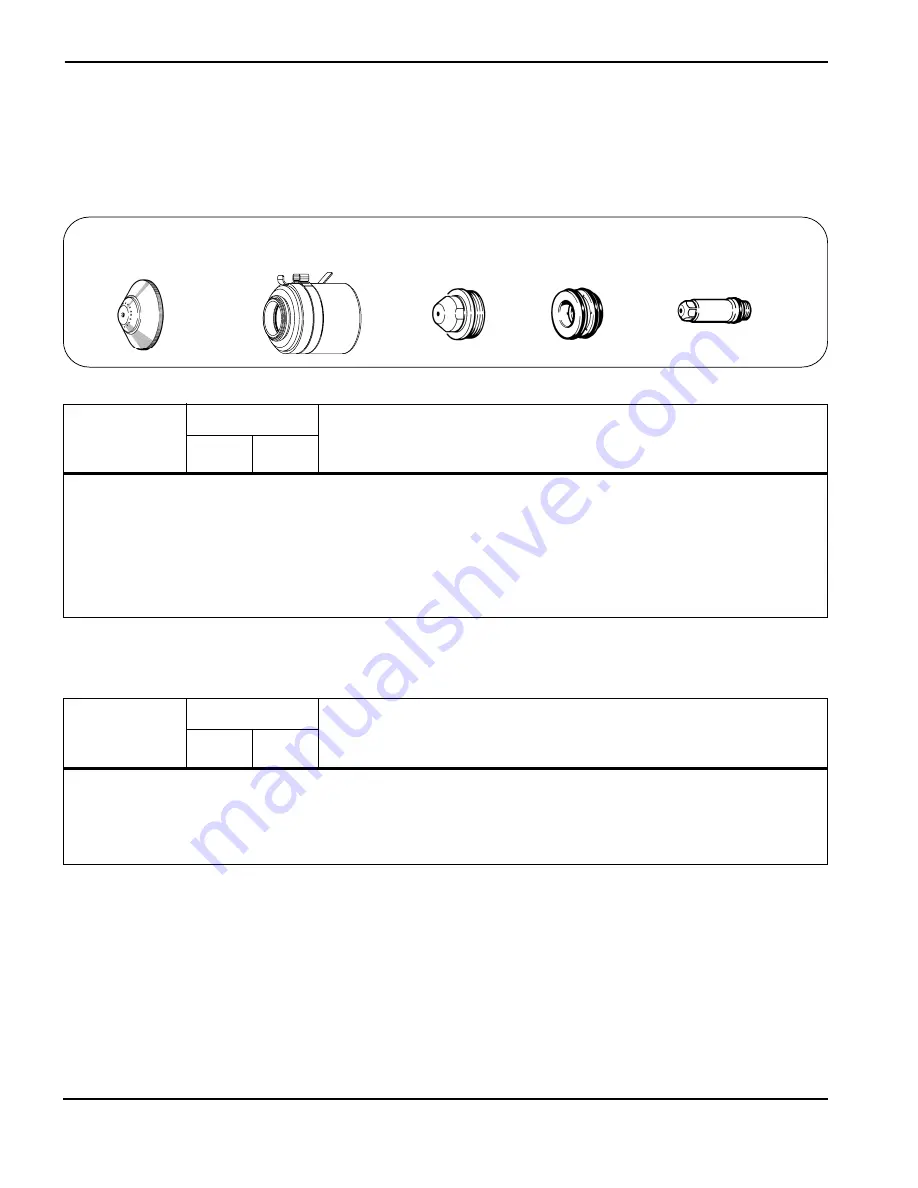

020448

Shield

120837

Retaining cap

020611

Nozzle

020607

Swirl ring

120547

Electrode

Summary of Contents for HT2000LHF

Page 1: ...200 Volt Plasma Arc Cutting System Instruction Manual 803040 Revision 7 HySpeed HT2000LHF ...

Page 5: ......

Page 15: ...TABLE OF CONTENTS viii Hyspeed HT2000LHF Instruction Manual 6 ...

Page 109: ...MAINTENANCE 5 20 HySpeed HT2000LHF Instruction Manual 7 ...

Page 133: ......

Page 134: ...7 5 7 Figure 7 1 HT2000LHF Coolant Flow Diagram ...

Page 135: ......

Page 136: ...7 7 7 ...

Page 137: ......

Page 138: ...7 9 7 ...

Page 139: ......

Page 140: ...7 11 7 ...

Page 141: ......

Page 142: ...7 13 7 ...

Page 143: ......

Page 144: ...7 15 7 ...

Page 145: ......

Page 146: ...7 17 7 ...

Page 147: ......

Page 148: ...7 19 7 ...

Page 149: ......

Page 150: ...7 21 7 ...

Page 151: ......

Page 152: ...7 23 7 ...

Page 153: ......

Page 154: ...7 25 7 ...

Page 155: ......

Page 157: ......

Page 159: ......

Page 174: ...APPENDIX A ARGON HYDROGEN CUTTING AND GOUGING a 14 HySpeed HT2000LHF Instruction Manual 6 ...

Page 176: ...b 2 ...

Page 177: ...b 3 ...

Page 178: ...b 4 ...

Page 179: ...b 5 ...

Page 181: ...b 7 ...

Page 182: ...b 8 ...

Page 183: ...b 9 ...

Page 184: ...b 10 ...

Page 194: ...APPENDIX E AIR FILTERS e 2 Hyspeed HT2000LHF Instruction Manual 6 ...

Page 196: ...APPENDIX F AERATION MANIFOLD FOR CUTTING ALUMINUM f 2 Hyspeed HT2000LHF Instruction Manual 6 ...

Page 198: ...APPENDIX G IEC SYMBOLS g 2 Hyspeed HT2000LHF Instruction Manual 6 ...