OPERATION

5-13

HT4001 Instruction Manual

DAILY START-UP

WARNING

Before operating this system, you must read the Safety section thoroughly! Wear

proper clothing. Your cutting environment must meet requirements outlined in the

Safety section. Turn main disconnect switches to the HT4001 power supply and

water chiller OFF before proceeding.

1.

Refer to the

Cut Charts beginning on page 5-21 to choose the correct consumables for

your cutting needs. Refer to

Changing Consumable Parts later in this section for de-

tailed information on the removal and replacement of consumables. Replace consum-

able parts, if needed.

2.

Verify that the torch is squared to the material and adjusted to the proper height. Refer to

Torch Alignment on page 4-38 for the torch alignment procedure. Refer to Pre-Operation

System Checkout in this section to adjust the torch height.

3.

Set S2 on the gas console to Run.

4.

Set the main disconnect switches for the power supply and the water chiller to ON.

5.

Turn the supply gases ON.

Set the pressure on the nitrogen supply to read 150 psi +/- 10 psi (10.3 bar +/- 0.7 bar)

at the N

2

pressure gauge on the gas console.

Set the pressure on the oxygen supply to read 120 psi +/- 10 psi (8.3 bar +/- 0.7 bar) at

the O

2

pressure gauge on the gas console.

6.

Turn the water supply to the water chiller ON.

7.

Turn on the water chiller by depressing the START switch.

8.

Set S1 on the gas console to plasma gas N

2

or O

2

.

9.

Turn on the power supply by throwing the POWER circuit breaker on the rear of the

power supply to the UP position.

10. Set the VOLTAGE from the Digital (DR) V/C module, or from the machine computer.

Select the arc voltage from the

Cut Charts for the type and thickness of metal to be cut.

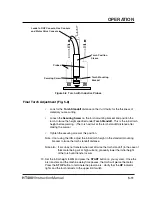

Setting the Current

When setting the CURRENT from a low value to a higher value:

Set the desired value on the V/C module or CNC programmable current device.

When setting the CURRENT from a high value to a lower value:

With the V/C module, dial the current to 50 amps below the desired value, and then back

up to the desired value.

When using a CNC programmable current device, set the current to the desired value

and then restart the plasma system.

6-98

Summary of Contents for HT4001

Page 1: ...Plasma Arc Cutting System Instruction Manual 802000 Revision 15 HT4001 EN50199 EN60974 1 ...

Page 239: ...e 2 ...

Page 240: ...e 3 ...

Page 241: ...e 4 ...

Page 242: ...e 5 ...

Page 244: ...e 7 ...

Page 245: ...e 8 ...

Page 246: ...e 9 ...

Page 247: ...e 10 ...

Page 257: ...KY ...

Page 258: ...KY ...

Page 259: ...KY ...

Page 260: ...KY ...

Page 261: ...KY ...

Page 262: ...KY ...

Page 263: ...KY ...

Page 264: ...KY ...

Page 268: ...KY ...

Page 269: ...KY ...

Page 270: ...KY ...