5-32

HT4001 Instruction Manual

C

U

T

C

H

A

R

T

S

HT4001 w/Slave

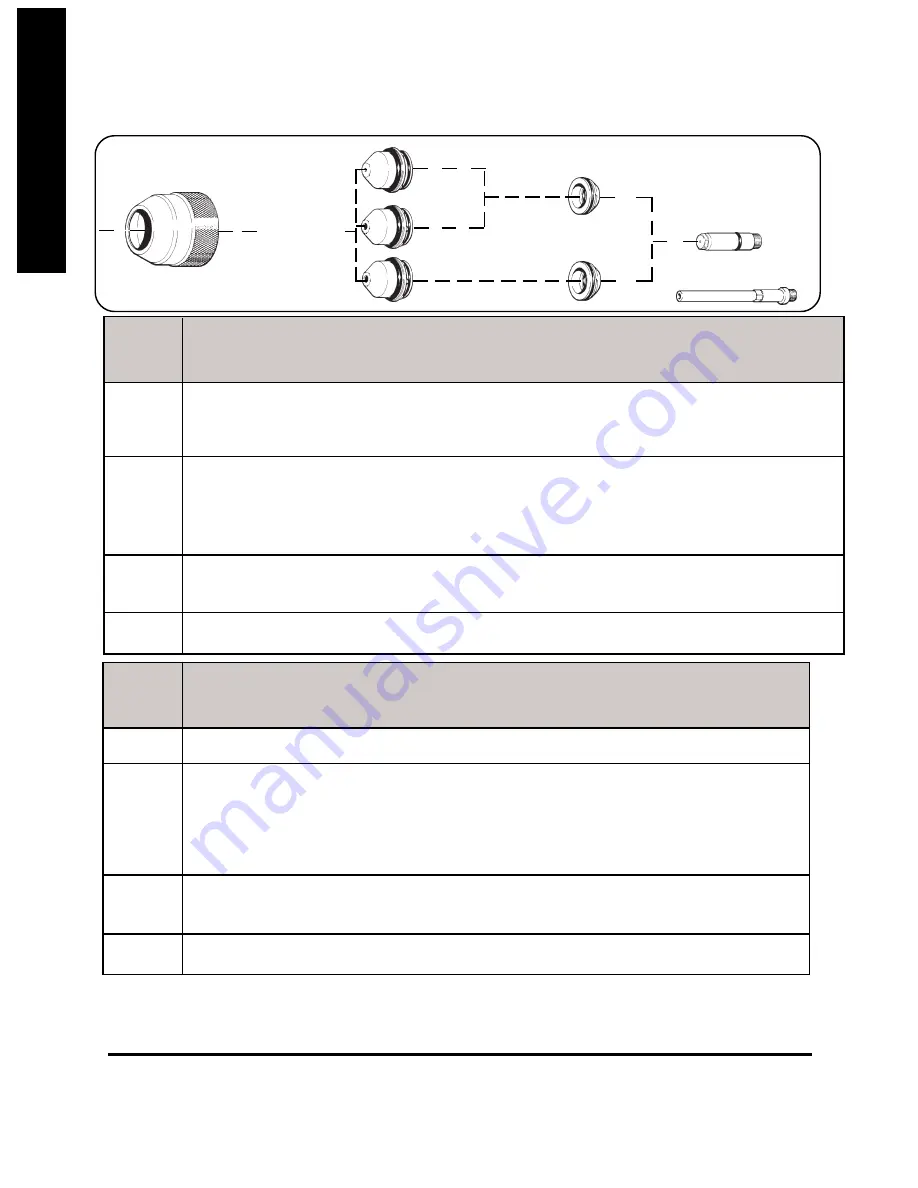

PAC620 Torch - Beveling Consumables

Aluminum - Nitrogen Plasma

Retaining Cap

120390 (Vect)

120391 (Vesp)

120470 - CE (Vect)

120471 - CE (Vesp)

Nozzle

120386

(.120 in/3 mm)

120387

(.166 in/4.2 mm)

120388

(.187 in/4.7 mm)

120389

(.220 in/5.5 mm)

Swirl Ring

020039 (cw)

020042 (ccw)

020040 (cw)

020079 (ccw)

Electrode

020968

Water Tube - N

2

Bevel

020991

.120"

260A max.

.166"

400A max.

.187"

600A max.

.220"

760A max.

Test Preflow

Rate

(N

2

)

(%)

Water Flow

Setting

(%)

45

62

62

62

62

62

62

62

65

65

65

73

73

Arc

Current

(A)

260

320

340

340

360

360

380

380

560

600

600

740

760

Arc

Volts

(V)

140

150

150

150

150

150

150

165

170

170

170

190

200

Torch

Standoff

(mm)

Travel

Speed

(mm/min)

6

6

6

6

6

7

8

10

10

10

10

14

16

4500

4350

3700

3200

2900

2350

1400

930

1460

1100

650

680

520

Test Cut Flow

Rate

(N

2

)

(%)

30

55

55

55

55

55

55

55

55

55

55

60

60

30

55

55

55

55

55

55

55

55

55

55

60

60

Material

Thickness

(mm)

6

6

8

10

12

15

20

25

30

35

50

60

75

3 mm

260A max.

4.2 mm

400A max.

4.7 mm

600A max.

5.5 mm

760A max.

Notes:

•

Minimum N

2

inlet supply pressure remains at one setting of 150 psi (10.3 bar) for all material thickness.

•

Water chiller pump outlet pressure remains between 175-185 psi (12-12.8 bar) for all material thickness.

•

N

2

flow rate at full scale is 374 scfh (176 l/min) @ 150 psi (10.3 bar) inlet pressure.

•

Set initial torch height (before piercing) to approximately twice the Torch Standoff distance for the material you are cutting.

Note: If arc does not transfer when set at twice the torch standoff (in the case of thick metal being cut at high current). gradually lower the initial height of the torch until transfer occurs.

M

E

T

R

I

C

E

N

G

L

I

S

H

Nozzle

Nozzle

Material

Thickness

(in) (mm)

Travel

Speed

(ipm) (mm/min)

520

345

230

170

220

165

130

110

60

35

70

35

25

30

20

13200

8760

5840

4320

5590

4190

3300

2790

1520

890

1780

890

630

760

510

Torch

Standoff

(in) (mm)

1/8

1/8

3/16

1/4

1/4

1/4

1/4

1/4

5/16

3/8

3/8

3/8

3/8

1/2

5/8

3

3

5

6

6

6

6

6

8

10

10

10

10

13

16

.035

.075

1/8

1/4

1/8

1/4

3/8

1/2

3/4

1

1

1-1/2

2

2

3

.889

1.91

3.18

6.35

3.18

6.35

9.53

12.7

19.1

25.4

25.4

38.1

50.8

50.8

76.2

Test Preflow

Rate

(N

2

)

(%)

30

30

30

30

55

55

55

55

55

55

55

55

55

60

60

Test Cut Flow

Rate

(N

2

)

(%)

30

30

30

30

55

55

55

55

55

55

55

55

55

60

60

Water Flow

Setting

(%)

45

45

45

45

62

62

62

62

62

62

65

65

65

73

73

Arc

Volts

(V)

120

125

130

140

140

150

150

150

150

165

165

170

170

175

200

Arc

Current

(A)

240

240

260

260

280

320

340

360

380

380

500

600

600

700

760

11-96

Summary of Contents for HT4001

Page 1: ...Plasma Arc Cutting System Instruction Manual 802000 Revision 15 HT4001 EN50199 EN60974 1 ...

Page 239: ...e 2 ...

Page 240: ...e 3 ...

Page 241: ...e 4 ...

Page 242: ...e 5 ...

Page 244: ...e 7 ...

Page 245: ...e 8 ...

Page 246: ...e 9 ...

Page 247: ...e 10 ...

Page 257: ...KY ...

Page 258: ...KY ...

Page 259: ...KY ...

Page 260: ...KY ...

Page 261: ...KY ...

Page 262: ...KY ...

Page 263: ...KY ...

Page 264: ...KY ...

Page 268: ...KY ...

Page 269: ...KY ...

Page 270: ...KY ...