Maintenance

HPR130XD Auto Gas –

806330

5-19

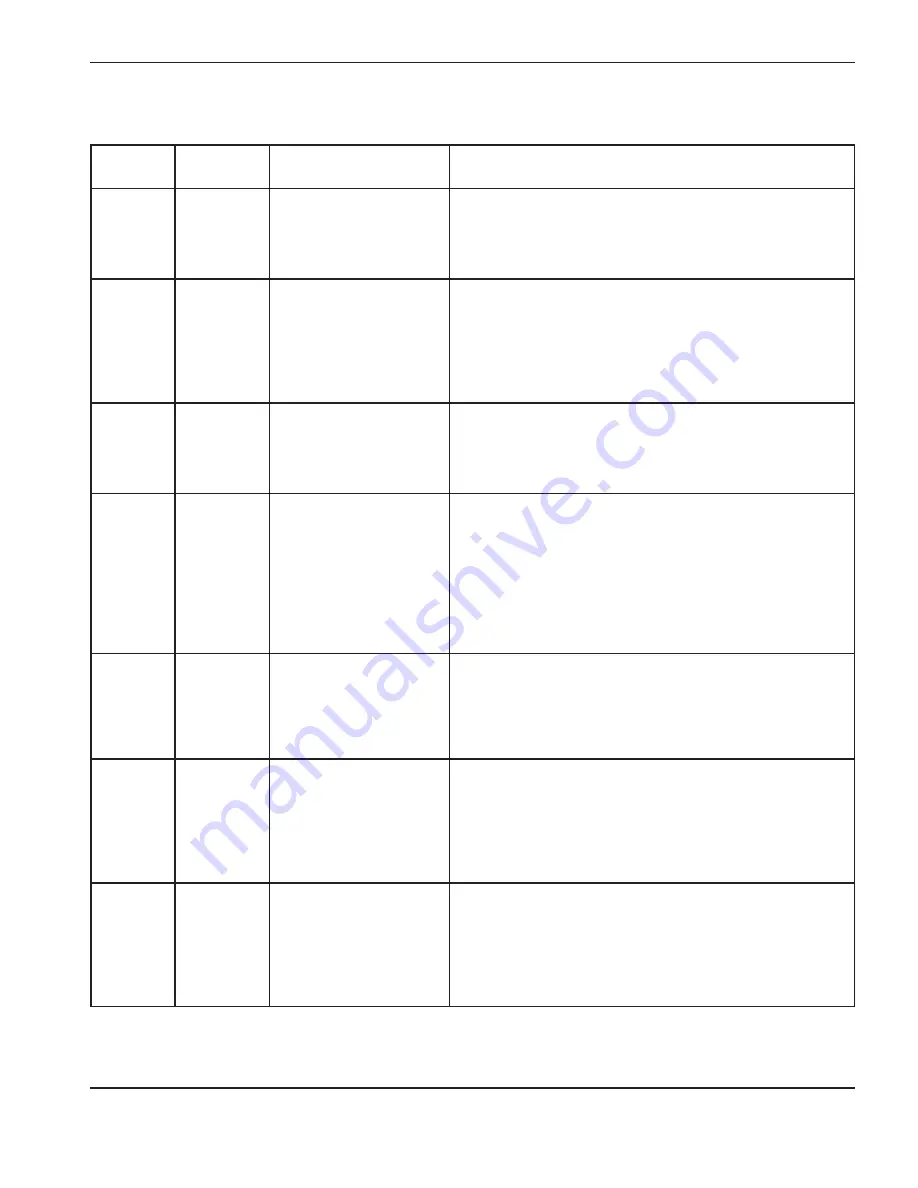

Error code troubleshooting – error codes 076 to 101, 276 to 301

Error code

number

Name

Description

corrective action

076

Primary

276

Secondary

Low current

on CS4

HPR400XD

only

A current less than

10 amperes has been

detected by

current sensor 4.

See the chopper test later in this section.

093

No coolant

flow

Coolant flow signal was

lost or never was satisfied.

1. If this is a new system, follow start procedure.

2. Verify that the coolant filter is in good condition.

3. Perform coolant flow tests (

Maintenance

section).

4. Verify that the CNC drives the plasma start signal for at

least 10 seconds to allow the timed-out pump to turn on

again.

095

Primary

295

Secondary

High current

on CS4

HPR400XD

only

A current greater

than 35 amperes has

been detected by

current sensor 4.

See the chopper test later in this section.

098

Phase loss at

initialization

HPR400XD

HPR800XD

only

The system detected

incoming line voltage

during power-up, before

the contactor was

energized.

1. Verify phase-to-phase voltage to power supply.

2. Disconnect power to power supply, remove cover on

contactor and inspect contacts for excessive wear.

3. Inspect power cord, contactor, and input to chopper for

loose connections.

4. Inspect phase loss fuses on Power Distribution board.

Replace board if fuses are blown.

5. Perform phase loss test (see

Maintenance

section).

099

Primary

299

Secondary

Chopper 1

overtemp at

power-up

Chopper 1 is indicating

an overtemp at power-up.

1. Verify that the temperature sensor for the chopper has not

been bypassed or that the wires to the temperature switch

are shorted out in the harness, or that the sensor is open.

2. If no jumper is present, the chopper is overheated and

needs time to cool to 83°C (181.4°F).

100

Primary

300

Secondary

Chopper 2

overtemp at

power-up

HPR260XD

HPR400XD

only

Chopper 2 is indicating

an overtemp at power-up.

1. Verify that the temperature sensor for the chopper has not

been bypassed or that the wires to the temperature switch

are shorted out in the harness, or that the sensor is open.

2. If no jumper is present, the chopper is overheated and

needs time to cool to 83°C (181.4°F).

101

Primary

301

Secondary

Magnetics

overtemp at

power-up

Main transformer is

indicating an overtemp at

power-up.

1. Verify that the transformer temperature sensor has not

been bypassed or the wires to the temperature sensor are

not shorted out in the harness.

2. Verify that the sensor is not open or shorted, if it is not

open or shorted, the main transformer is overheated and

needs time to cool to 150°C (302°F).

Summary of Contents for HyPerformance HPR130XD

Page 1: ...HyPerformance Plasma HPR130XD Auto gas Instruction manual 806330 Revision 3 ...

Page 16: ...Table of Contents viii HPR130XD Auto Gas 806330 ...

Page 26: ...Specifications 2 2 HPR130XD Auto Gas 806330 ...

Page 38: ...Specifications 2 14 HPR130XD Auto Gas 806330 ...

Page 48: ...Installation 3 10 HPR130XD Auto Gas 806330 ...

Page 59: ...Installation HPR130XD Auto Gas 806330 3 21 1X1 J103 J300 Female Male 5 6 5 6 3X1 3X2 3X3 3X4 ...

Page 94: ...Installation 3 56 HPR130XD Auto Gas 806330 ...

Page 101: ...Operation HPR130XD Auto Gas 806330 Revision 2 4 7 Diagnostics screen ...

Page 102: ...Operation 4 8 HPR130XD Auto Gas 806330 Revision 2 Test screen ...

Page 103: ...Operation HPR130XD Auto Gas 806330 Revision 2 4 9 Cut chart screen ...

Page 152: ...Operation 4 58 HPR130XD Auto Gas 806330 Revision 2 ...

Page 236: ...7 4 HPR130XD Auto Gas 806330 Discrete output functionality ...

Page 294: ...Appendix B CNC Interface Protocol b 28 HPR130XD Auto Gas 806330 Revision 1 ...

Page 302: ...4 HPR130XD Auto Gas 806330 ...