Maintenance

HPR130XD Auto Gas –

806330

5-35

2

3

4

5

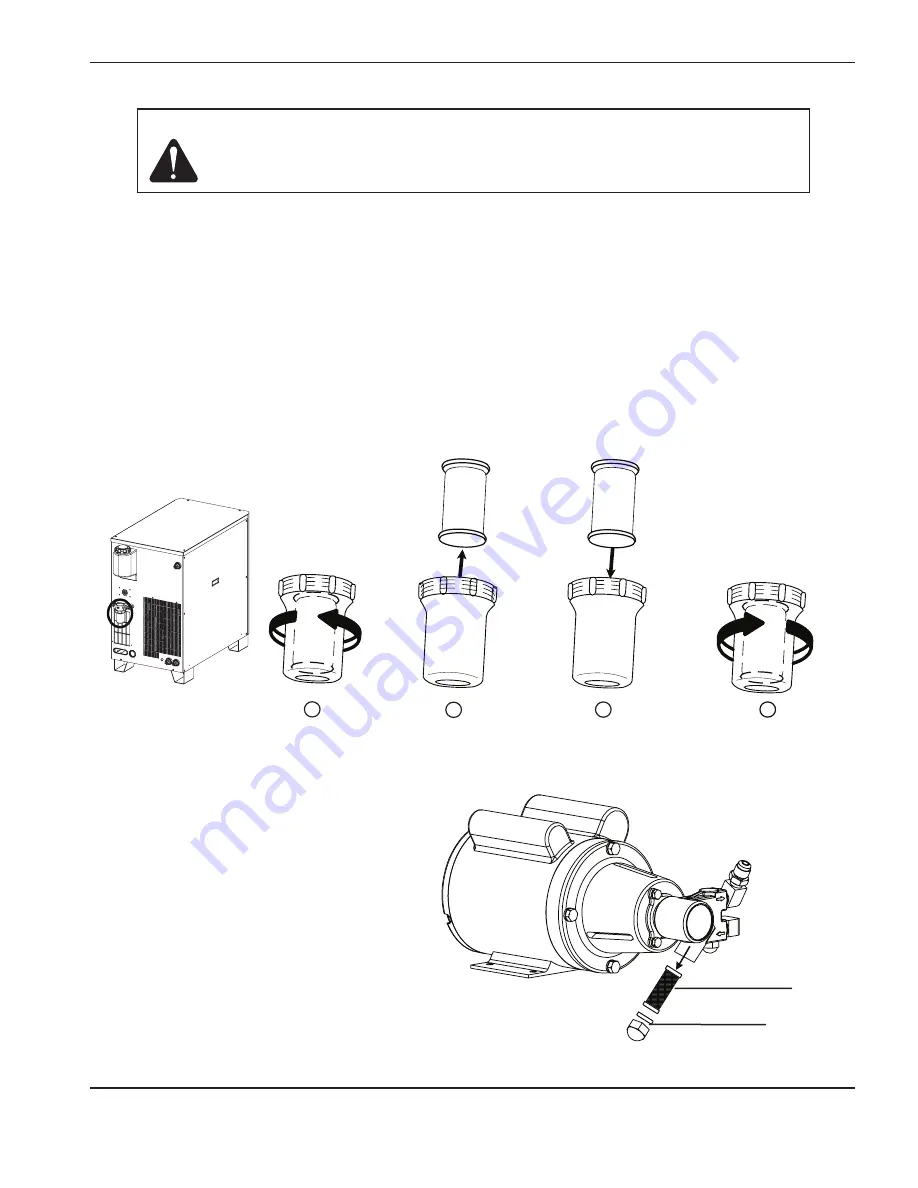

coolant system filter and strainer

Filter replacement

1. Turn OFF all power to the system.

2. Remove housing.

3. Remove and discard filter element.

4. Install new filter element 027664.

5. Re-install housing.

6. Refill with new coolant.

Pump strainer cleaning

1. Turn OFF all power to the system.

2. Drain coolant. See

Power supply coolant

draining

in this section.

3. Remove nut.

4. Remove and clean strainer with a mild soap

and water solution.

5. Re-insert strainer.

6. Re-install nut.

7. Refill with new coolant.

Nut

Strainer

caution: coolant will flow from the filter when its housing is removed. Drain coolant

before servicing the filter.

Summary of Contents for HyPerformance HPR130XD

Page 1: ...HyPerformance Plasma HPR130XD Auto gas Instruction manual 806330 Revision 3 ...

Page 16: ...Table of Contents viii HPR130XD Auto Gas 806330 ...

Page 26: ...Specifications 2 2 HPR130XD Auto Gas 806330 ...

Page 38: ...Specifications 2 14 HPR130XD Auto Gas 806330 ...

Page 48: ...Installation 3 10 HPR130XD Auto Gas 806330 ...

Page 59: ...Installation HPR130XD Auto Gas 806330 3 21 1X1 J103 J300 Female Male 5 6 5 6 3X1 3X2 3X3 3X4 ...

Page 94: ...Installation 3 56 HPR130XD Auto Gas 806330 ...

Page 101: ...Operation HPR130XD Auto Gas 806330 Revision 2 4 7 Diagnostics screen ...

Page 102: ...Operation 4 8 HPR130XD Auto Gas 806330 Revision 2 Test screen ...

Page 103: ...Operation HPR130XD Auto Gas 806330 Revision 2 4 9 Cut chart screen ...

Page 152: ...Operation 4 58 HPR130XD Auto Gas 806330 Revision 2 ...

Page 236: ...7 4 HPR130XD Auto Gas 806330 Discrete output functionality ...

Page 294: ...Appendix B CNC Interface Protocol b 28 HPR130XD Auto Gas 806330 Revision 1 ...

Page 302: ...4 HPR130XD Auto Gas 806330 ...