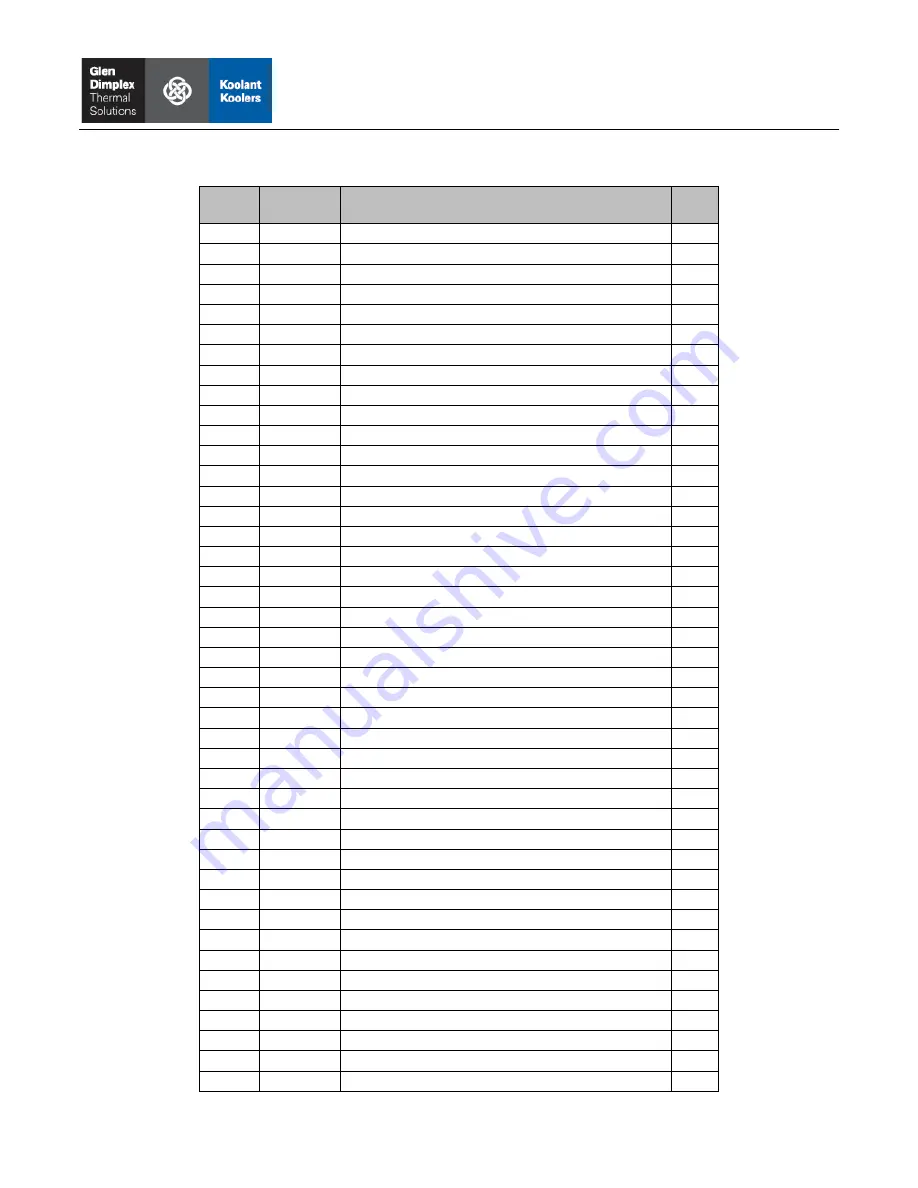

Appendix

B

(Electrical

Schematics)

63

Electrical

BOM

Table

11:

Electrical

Panel

Bill

of

Materials

ITEM

NO.

PART

NUMBER

DESCRIPTION

QTY.

1

204042

PANEL

‐

EBOX,

30"

X

36"

1

2

5002086

30A,MOLDED

CASE

CB,

E

FRAME,TYPE

H

1

3

5001779

EG

HANDLE

KIT

1

4

5001786

3

TERMINAL

LUGS

EG

FRAM

MCCB

2

‐

14AWG

1

5

5000472

PHASE

MONITOR

3PH

1.8VA

1

6

5001600

400

‐

500VAC

240W

24VDC

PSU

1

7

5003655

c.pCOe

BASIC

16

I/O

MODULE

1

8

5001634

CONNECTOR

KIT

FOR

C.PCOE

BASIC

1

9

5001058

RELAY

24VDC

10A

DPDT

W/DIODE

1

10

5001243

10

‐

16A

MANUAL

MOTOR

PROTECTOR

10

B

1

11

5000752

CONTACTOR

9A

24VDC

1NO

FRAME

B

2

12

5001574

MMP

CONNECTOR

SCREW

IN

FRAME

B

TO

B

3

13

5001576

MMP

LINE

SIDE

ADAPTER

FRAME

B

1

14

5000785

CIRCUIT

BREAKER

UL489

1P

7A

D

1

15

5000816

CIRCUIT

BREAKER

UL489

3P

1.5A

D

1

16

5000805

CIRCUIT

BREAKER

UL489

2P

8A

D

1

17

204668

CUT

DIN

RAIL,

17"LG

1

18

204669

CUT

DIN

RAIL,

5"LG

1

19

204671

CUT

DIN

RAIL,

12"LG

1

20

204672

CUT

DIN

RAIL,

16"LG

1

21

204674

CUT

WIRE

WAY,

29"LG

1

22

204675

CUT

WIRE

WAY,

12"LG

1

23

204676

CUT

WIRE

WAY,

13"LG

1

24

204677

CUT

WIRE

WAY,

16"LG

3

25

5000972

30/24A

TERMINAL

BLOCK

4

CONNECTIONS

36

26

5000973

30/24A

TERMINAL

BLOCK

END

BARRIER

11

27

5000971

END

CLAMP

QUICK

MOUNT

DIN

RAIL

13

28

5001573

MMP

FRONT

AUX

CONTACT

1NO

1NC

3

29

7719129

SCREW

1/4

‐

20

X

1

FLANGE

BOLT

1

30

7701028

SCREW

10

‐

32

X

3/8

HEX

THREAD

CUT

40

31

5000974

30/24A

GROUND

BLOCK

4

CONNECTIONS

5

32

9900106

GROUND

LABEL

1

33

204670

CUT

DIN

RAIL,

4"LG

1

34

5001569

1

‐

1.6A

MANUAL

MOTOR

PROTECTOR

10

B

2

35

5000755

CONTACTOR

18A

24VDC

1NO

FRAME

C

1

36

5003260

LABEL

‐

L1/U,

L2/V,

L3/W

1

37

5003712

PHYSICAL

EARTH

LABEL

1

38

7714006

NUT

1/4

‐

20

K

LOCK

NUT

1

39

7714001

NUT

1/4

‐

20

HEX

NUT

1

40

5003585

GROUND

LUG,

2

BARREL

14

‐

1/0

AWG

1

41

5001871

MMP

COMMONING

LINK

3

DEVICES

FRAME

A

1

42

5000823

CIRCUIT

BREAKER

UL489

3P

8A

D

1

43

5001057

RELAY

24VDC

6A

SPDT

W/DIODE

1

Hypertherm, Inc. Part Number: 810540

Summary of Contents for Koolant Koolers N-Series

Page 61: ...Appendix B Electrical Schematics PLC 59 PLC Hypertherm Inc Part Number 810540...

Page 62: ...Appendix B Electrical Schematics I O Module 60 I O Module Hypertherm Inc Part Number 810540...

Page 63: ...Appendix B Electrical Schematics Logic 61 Logic Hypertherm Inc Part Number 810540...

Page 73: ...Appendix E Declaration of Conformity 71 Hypertherm Inc Part Number 810540...

Page 74: ...Appendix E Declaration of Conformity 72 Hypertherm Inc Part Number 810540...

Page 75: ...Appendix E Declaration of Conformity 73 Hypertherm Inc Part Number 810540...