MAXPRO200

Instruction Manual 807700 Revision 1

51

Installation

Note:

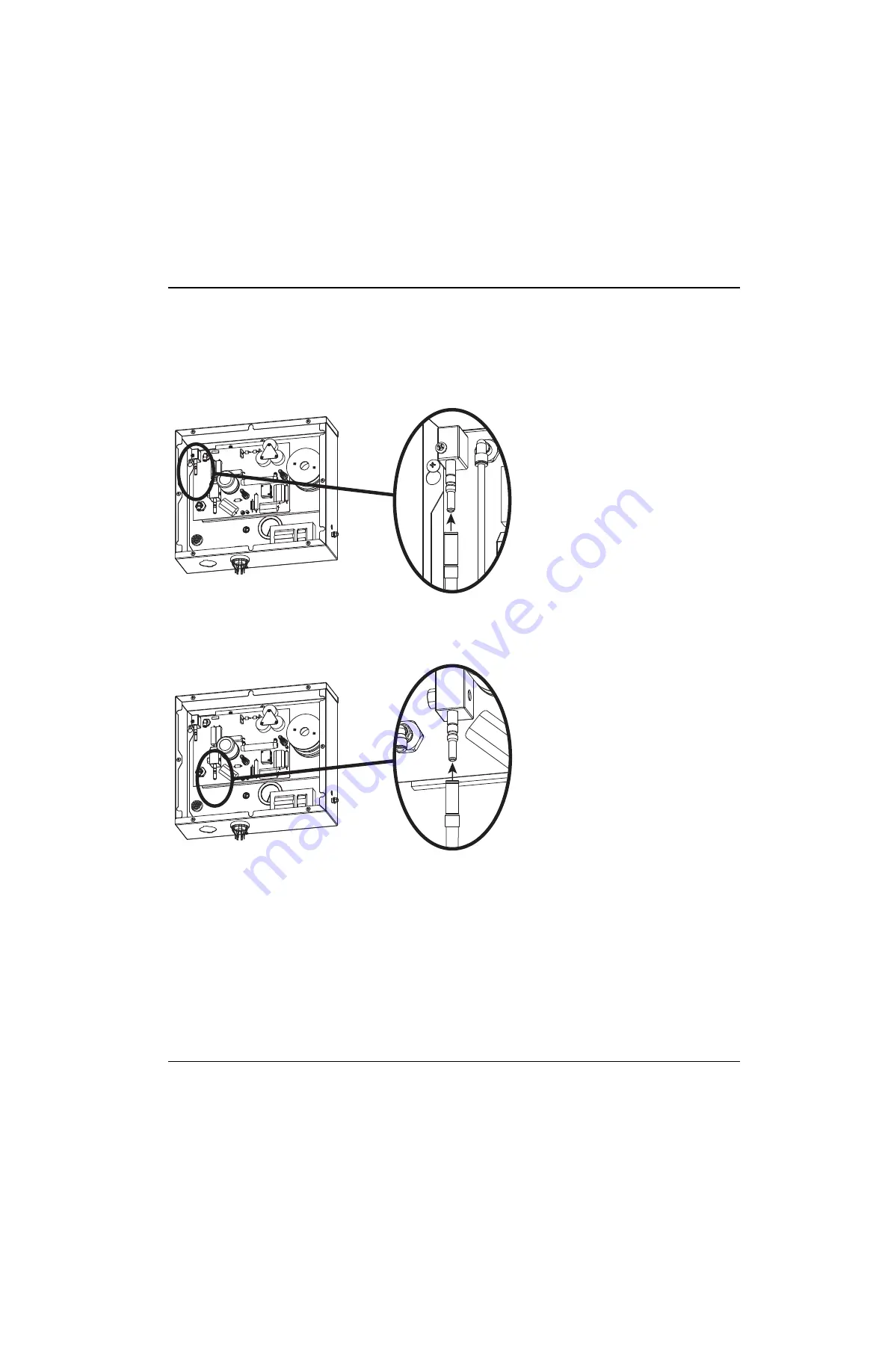

The shield gas/pilot arc and coolant supply/negative lead hose connectors mentioned below are slightly

different push-to-connect fittings. Slide the hose fitting over the connector and press until it clicks into place. To

disconnect a fitting, pull the connector-collar toward the hose, and pull the hose away from the fitting.

5.

Connect the pilot arc/shield gas hose (blue).

6.

Connect the negative lead/coolant supply hose (blue with green tape).

Summary of Contents for MAXPRO200

Page 1: ...MAXPRO200 Instruction Manual 807700 Revision 1 ...

Page 26: ...22 MAXPRO200 Instruction Manual 807700 Revision 1 Safety ...

Page 34: ...30 MAXPRO200 Instruction Manual 807700 Revision 1 Product Stewardship ...

Page 38: ...34 MAXPRO200 Instruction Manual 807700 Revision 1 Specifications ...