4-12

O

PERATION

Operator Manual

Recommended

Material

Arc

Arc

Travel

Pierce

Thickness Material Current

Voltage

Speed*

Delay

(in.) (mm)

(A)

(V) (ipm) (mm/min ) (S)

3/16"

4.8

Mild steel

80

115

160

4060

0

1/4"

6.4

Mild steel

80

117

110

2800

0.25

3/8"

9.5

Mild steel

80

116

57

1450

0.50

1/2"

12.7

Mild steel

80

120

38

965

0.75

5/8"

15.9

Mild steel

80

124

25

635

1.75

3/4"

19.0

Mild steel

80

124

20

510

n/a

7/8"

22.2

Mild steel

80

132

14

355

n/a

1"

25.4

Mild steel

80

133

11

280

n/a

3/16"

4.8

Stainless Steel

80

120

160

4060

0.25

1/4"

6.4

Stainless Steel

80

121

100

2540

0.50

3/8"

9.5

Stainless Steel

80

122

53

1345

1.00

1/2"

12.7

Stainless Steel

80

123

32

810

1.25

5/8"

15.9

Stainless Steel

80

123

25

635

1.75

3/4"

19.0

Stainless Steel

80

126

18

460

n/a

1"

25.4

Stainless Steel

80

133

10

255

n/a

1/8"

3.2

Aluminum

80

119

340

8640

0

1/4"

6.4

Aluminum

80

120

140

3560

0.25

3/8"

9.5

Aluminum

80

122

90

2285

0.50

1/2"

12.7

Aluminum

80

129

60

1525

1.00

3/4"

19.0

Aluminum

80

131

31

790

n/a

* Recommended travel speeds are 10–20% slower than maximum. These slower speeds will produce optimum

cut quality.

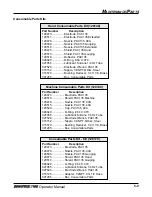

CUT CHART - 80A STANDARD CONSUMABLES

The following recommended settings are for mechanized cutting. Torch-to-work distance is 1/16 inch

(1.6 mm) for all cuts.

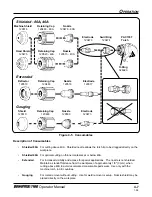

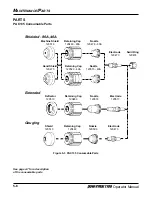

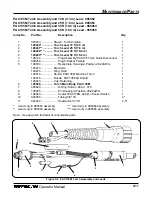

Shield

120516

Retaining Cap

120483 - 80A

Electrode

120473

Swirl Ring

120474

Nozzle

120476 - 80A