b-1

AERATION MANIFOLD FOR PLASMA CUTTING ALUMINUM

Introduction

When plasma arc cutting aluminum at the water table surface or below water, free hydrogen gas may

be generated by the cutting process. The high temperature of the plasma process causes

disassociation of oxygen and hydrogen from the water in the water table. The hot aluminum, which has

a high affinity for oxygen, then combines with the oxygen leaving free hydrogen.

An effective means of avoiding free hydrogen buildup is to install an aeration manifold on the floor of

the water table to replenish the oxygen content of the water.

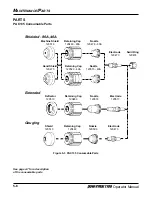

Making an Aeration Manifold - Figure b-1

Make an Aeration Manifold with two-inch (50 mm) PVC tubing with one-inch (25 mm) Distribution

Lines connected to it. Drill 1/8 inch (3 mm) holes every six inches (150 mm) in the distribution lines.

Cap the ends of the distribution lines and install the lines so that oxygen is delivered to all parts of the

cutting area.

Connect the manifold to a shop air line. Set a pressure regulator to obtain a steady stream of bubbles.

Figure b-1 Aeration Manifold

Regulated air in

Distribution Lines

Aeration Manifold

A

PPENDIX

B

Operator Manual

A

ERATION

M

ANIFOLD