Powermax125

Service Manual 808070

147

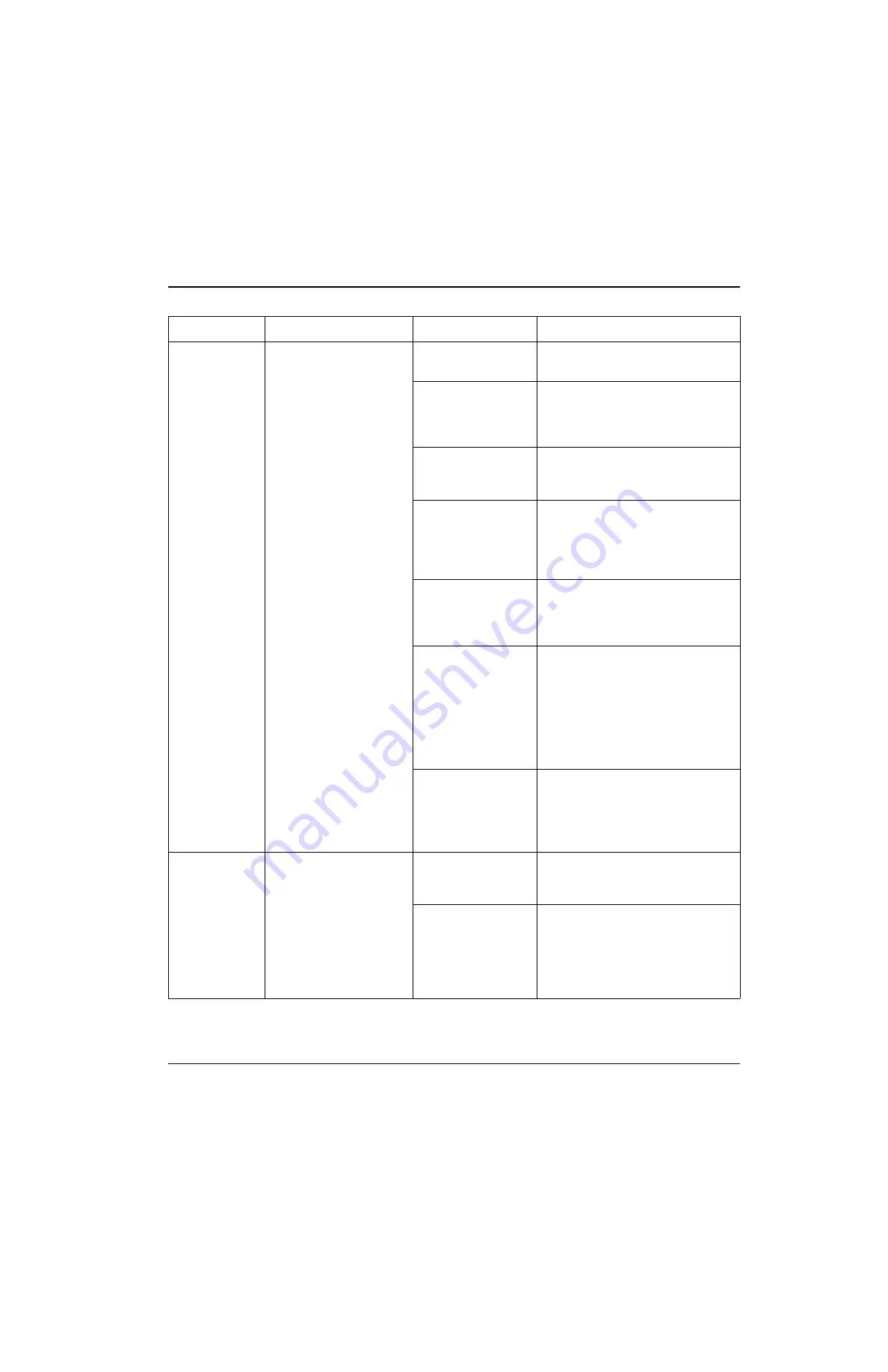

8 – Troubleshooting and System Tests

The cut quality is

poor, or the cut

does not sever the

metal.

• Worn consumables

• Poor work lead

connection

• Low output power from

the power supply

• the power board is

producing low current

• Incorrect cutting mode is

selected

• Poor air quality

• The consumables

need to be replaced.

• Inspect the consumables and replace

them if necessary.

• The work lead may

be damaged or not

properly connected

to the workpiece.

• Inspect the work lead for damage.

Reposition it and clean the work

surface to allow good contact.

• The amperage

adjustment knob is

set too low.

• Increase the amperage as needed.

• The power board

may be faulty.

on page 154 and replace any

faulty components.

• The cutting mode

switch is in the

wrong position for

the cutting operation.

• Verify that the cutting mode switch is

in the correct position.

• Faulty pilot arc IGBT. • 1) Turn the power OFF, 2) remove the

consumables, and 3) check the

resistance between the cathode and

the ground clamp.

• If the resistance is less than 5 kΩ,

check the resistance across the pilot

arc IGBT. If that resistance is less

than 5 kΩ, replace the pilot arc IGBT.

• Gas filter element is

dirty.

• Oil, moisture, or

contaminants in the

gas supply line.

• Replace the gas filter element.

• Add appropriate filtration, and purge

the lines with nitrogen to flush out oil

and moisture.

While in

continuous pilot

arc mode, the

pilot arc

extinguishes when

you move the

plasma arc off the

workpiece while

still pulling the

torch’s trigger.

The continuous pilot arc

feature is not working.

• The mode switch

may be set

incorrectly.

• Verify that the mode switch is set to

continuous pilot arc.

• The power board or

the DSP board may

be faulty.

on page 154 and replace the

power board or DSP board if

necessary.

Problem

Meaning

Causes

Solution