MAINTENANCE

3-4

powermax1650

Service Manual

0

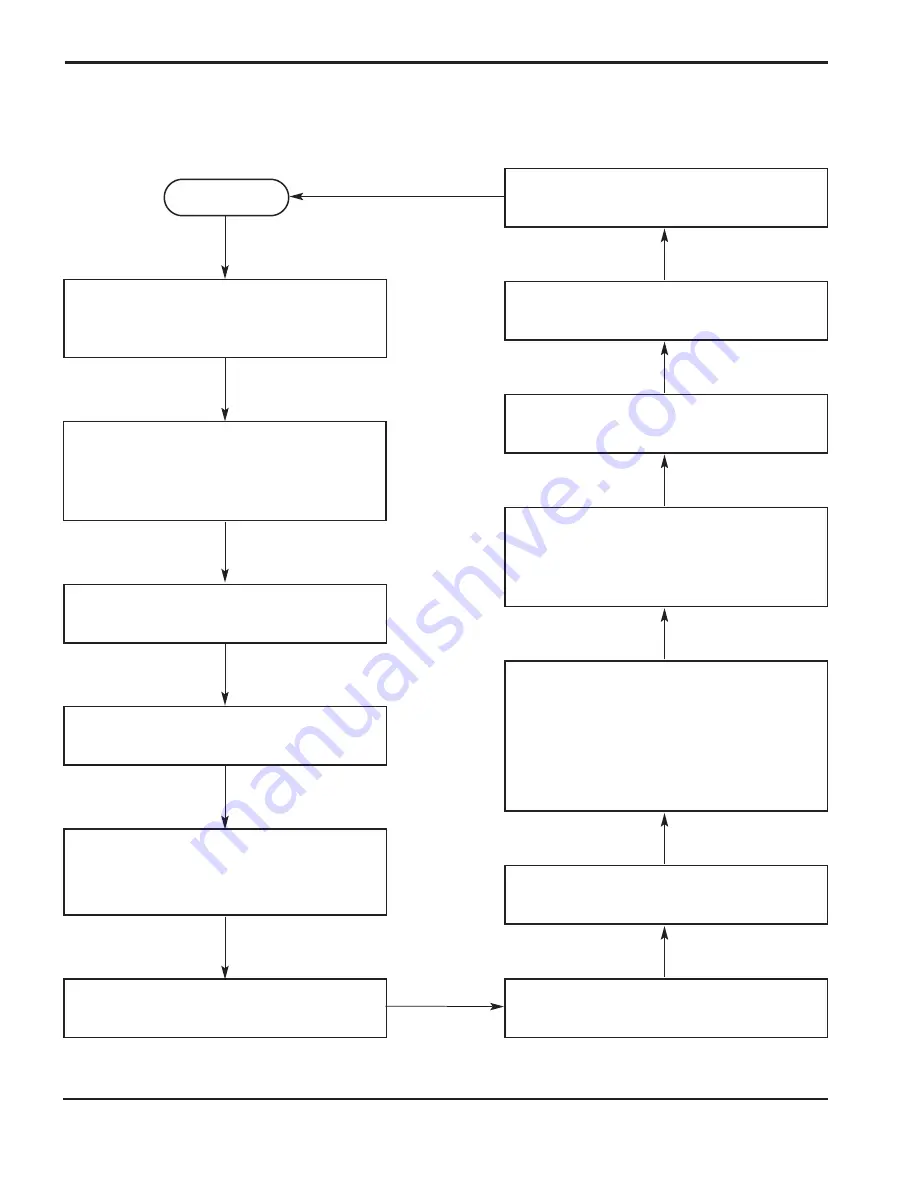

Sequence of Operation

System OFF

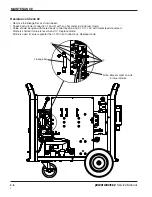

• Connect gas supply to filter on power unit.

• Connect work lead to work piece.

• Apply power at line voltage disconnect box.

• Set ON/OFF switch S1 to ON (I)

Set power switch S1 to OFF (0).

• Gas solenoid valve V1 closes.

• Gas flow stops.

• Consumables reseat.

• Arc extinguishes.

• Post flow continues for 30 seconds.

• Arc transfers to plate.

• Move torch to make cut.

• Work piece falls away after cut.

• Release plasma start switch on hand torch or

remote start switch for machine torch.

• Inverter starts.

• Current flows through torch with nozzle and

electrode shorted.

• Gas solenoid valve V1 opens.

• Gas flow starts.

• Torch "blows back" - nozzle and electrode

separate.

• Pilot arc starts.

• Position torch on work piece.

• Depress plasma start switch on hand torch or

remote start switch for machine torch.

Power circuits are ready.

• Gas solenoid valve V1 closes.

• Gas flow stops.

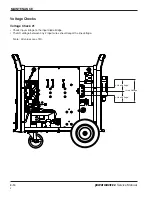

• Set gas pressure (see Setup section in

Operator Manual).

• Select desired cutting amps with current

adjustment knob.

Gas solenoid valve V1 opens to purge system

and to allow setting of pressure.

• Turn current adjustment knob

counterclockwise to gas test position.

• Check air pressure setting.

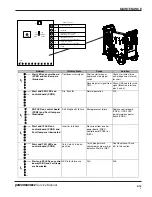

• Power ON lamp illuminates and Gas

Pressure LED illuminates green, indicating

system is ready for operation.

• Fault LEDs should not be illuminated (see

Troubleshooting for more information)