torch setup

powermax

45

Operator Manual

3-15

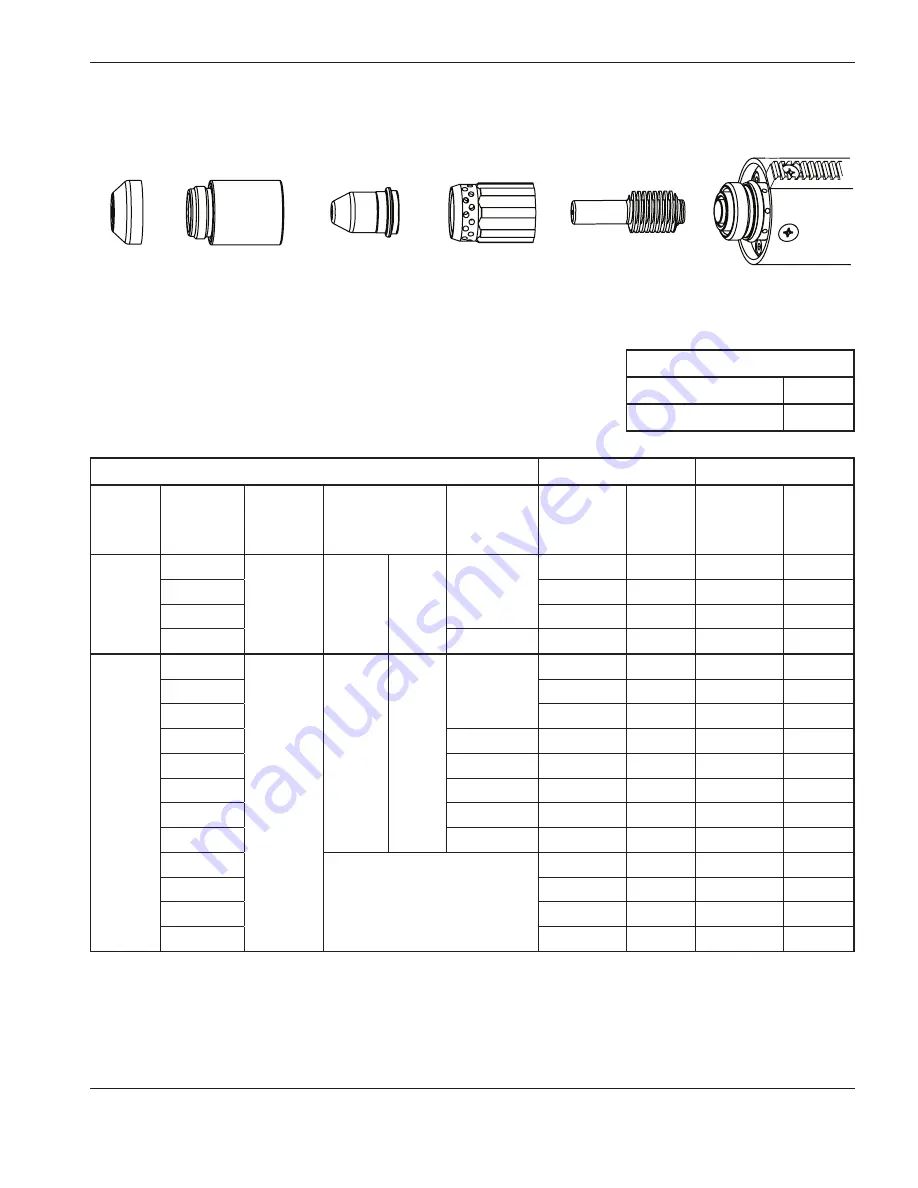

T45m unshielded consumables

220713

Retaining cap

220670

Swirl ring

220669

Electrode

220717

Deflector

220718

Nozzle

Mild steel

Air flowrate (lpm)

Metric

Hot

151

Cold

165.2

Recommended

Maximum

Arc

current

(amps)

Material

thickness

(mm)

Torch-

to-work

distance

(mm)

Initial pierce

height

Pierce time

delay

(sec)

Cut Speed

(mm/min)

Voltage

(V)

Cut Speed

(mm/min)

Voltage

(V)

30

0.5

2.0

5.0 mm

250%

0.0

9150

118

10160*

114

0.8

8650

118

10160*

116

0.9

8100

117

10160*

120

1.5

0.2

5800

113

7250

119

45

0.9

2.0

5.0 mm

250%

0.0

9650

118

10160*

110

1.5

8900

114

10160*

113

1.9

6100

114

7620

114

2.7

0.3

4450

116

5588

114

3.4

0.4

3400

118

4318

116

4.8

0.4

2150

118

2794

116

6.4

0.5

1500

118

1905

118

9.5

0.7

810

120

1016

118

12.7

Edge start recommended

510

130

635

124

15.9

280

132

356

126

19.1

200

138

254

132

25.4

100

145

127

140

*Maximum cut speed is limited by the test table’s maximum speed (10160 mm/min).

Summary of Contents for POWERMAX 45

Page 1: ...45 Plasma arc cutting system Operator Manual 805780 Revision 2 ...

Page 6: ......

Page 10: ...Table of Contents iv powermax45 Operator Manual ...

Page 30: ...Power supply setup 2 8 powermax45 Operator Manual ...

Page 74: ...operation 4 16 powermax45 Operator Manual ...

Page 84: ...Maintenance and Repair 5 10 powermax45 Operator Manual ...