DRAWN BY

QLIU

D

C

B

A

4

3

2

1

D

C

B

A

4

3

2

1

DATE

4/26/2010

PAGE

1 OF 2

TITLE

FILENAME

CUTTING FSM FAST LOOP BY QLIU.VSD

P.O.Box 5010

Hanover, NH 03755-5010

(603) 643-3441

Y

B

E

T

A

D

N

O

I

T

P

I

R

C

S

E

D

.

V

E

R

U

I

L

Q

8

2

-

4

0

-

9

0

0

2

e

s

a

e

l

e

R

l

a

it

i

n

I

A

REVISIONS

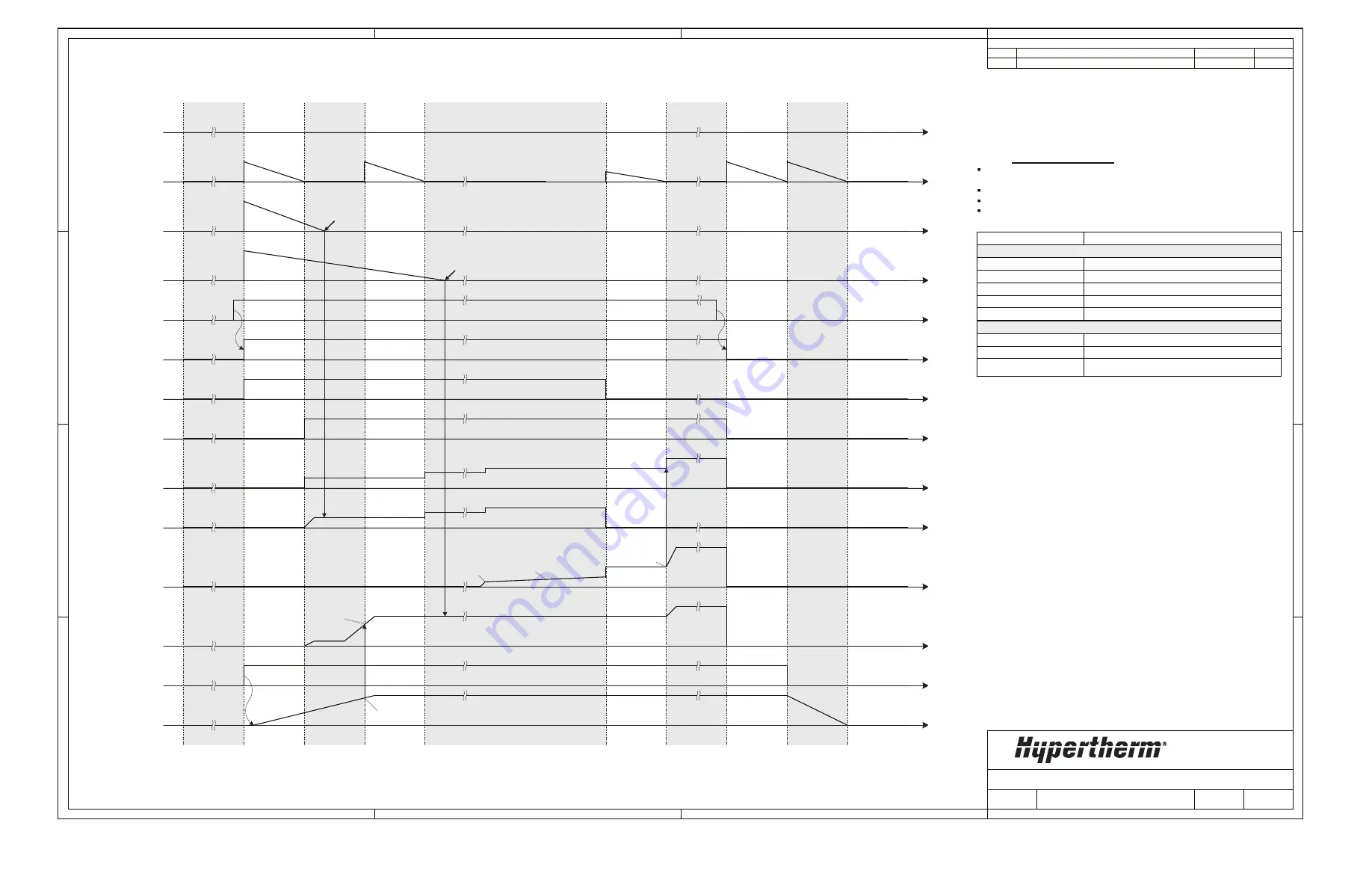

Start Switch

SEQ_State

IDLE

(0x0F)

Debounced

Start

Pilot Arc

Switch

Inverter

Enable

I

Command

I

Pilot

I

Work Lead

Arc

Voltage

Gas

Solenoid

Torch Gas

Pressure

SEQ_Timer

timer_TSC

5ms

2A/ms

GAS UP

(0x10)

T_PILOT_MIN

0.4A

T_GAS_UP

CUT

(0x40)

KNOB

POST FLOW

(0x60)

TORCH

RESET

(0x70)

IDLE

(0x0F)

8PSI

20s

T_TORCH_RESET

15A

15A

1.6A

2A/ms

PILOT

START

(0x20)

PILOT

(0x21)

KNOB

50V

TRANSFER

(0x30)

timer_TSO

T_TSO

Check TSO

T_TSC

Check TSC

INV ON

(0x11)

Torch gas ramping up delay

Description

Timeouts and Delays

Minimum pilot time delay

Delay from Gas Up to TSO test

Delay from Gas Up to TSC test

Torch consumable Reseat Time

Regular pilot current setting

Current Setpoints

Pilot current boost value

Assumptions:

This diagram represents most but not all possible State

transitions.

No Faults Occur.

System is not connected to a Load Bank.

System is running at Normal Mode at normal input line voltage.

Mnemonic

T_GAS_UP

T_PILOT_MIN

T_TSO

T_TSC

T_TORCH_RESET

pilot_current_set

I_PILOT_HIGH_DELTA

pilot_current_set

pilot_current_set

pilot_curre

I_PILOT_HIGH_DELTA

pilot_curre

I_PILOT_HIGH_DELTA

I_TRANSFER

I_TRANSFER

Transfer current = pilot_current_set

+ I_PILOT_HIGH_DELTA

I_TRANSFER

CUTTING FSM TIMGING DIAGRAM -NORMAL

8-3

Cutting timing diagram page 1 of 2

Summary of Contents for Powermax 65

Page 1: ...Service Manual 807120 Revision 1 Plasma arc cutting systems ...

Page 10: ...vi powermax65 85 Service Manual ...

Page 16: ...Table of Contents xii powermax65 85 Service Manual ...

Page 32: ...Specifications 1 16 powermax65 85 Service Manual ...

Page 182: ...Troubleshooting and System Tests 5 56 powermax65 85 Service Manual ...

Page 216: ...Component Replacement 6 34 powermax65 85 Service Manual ...

Page 244: ...Wiring Diagrams 8 2 powermax65 85 Service Manual ...