230V CE INSTALLATION

2-6

230V CE Installation Manual

ATTACHING POWER SUPPLY BRACKET TO POWERMAX900 CE

CHASSIS.

1.

If torch is connected to power supply, disconnect it.

WARNING

INSTALLATION MUST BE PERFORMED ONLY BY HYPERTHERM DISTRIBUTORS OR

QUALIFIED ELECTRONICS TECHNICIANS!!

SHOCK HAZARD: Always turn off power, unplug cord from wall and wait 5 minutes before

removing any cover of the power supply! If power unit is directly connected to a line

disconnect box, place line disconnect switch to OFF position and remove power cord from

line disconnect box.

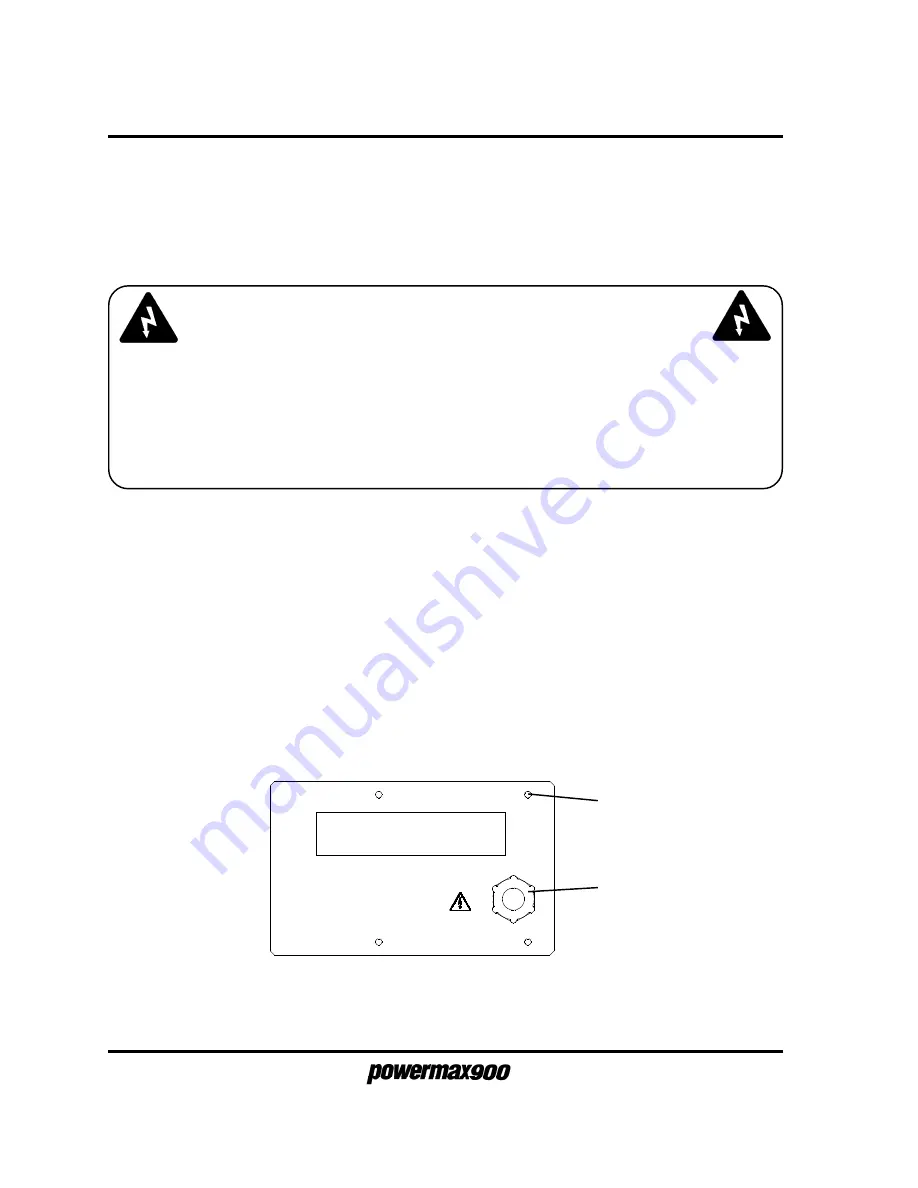

Figure 2-4 Removal of Power Cord from Powermax900 CE Power Supply - 1 of 2

Remove screws to remove

line cord rear panel and

expose filter board and TB1.

2.

Remove power cord from line disconnect box or from receptacle.

3.

Remove power cord from power supply. See Figure 2-4.

3.1. Loosen the power cord strain relief.

3.2. Remove the screws securing the line cord rear panel.

3.3. Slide rear panel down on power cord to expose filter board and TB1.

3.4. Disconnect power cord from TB1 and ground stud. See Figure 2-5.

Loosen power cord

strain relief.