MAINTENANCE AND PARTS

1

powermax30

Operator Manual

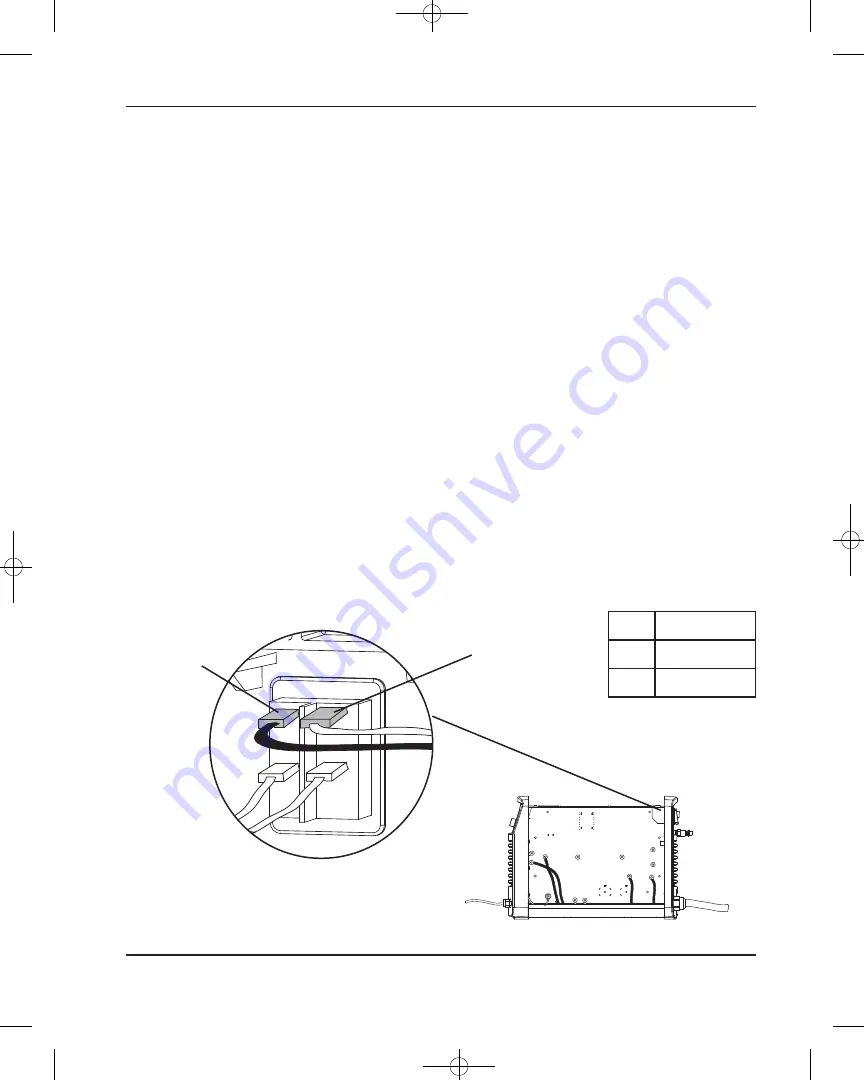

5-17

15. Replace the endcap.

16. Replace the Nomex barrier and slide the cover back onto the power supply. Position the

handle over the holes in the top of the cover, then use the 2 screws to secure the cover.

17. Reconnect the electrical power and the gas supply.

L

Brown wire

N

Blue wire

Replace the power cord (CE)

1. Turn OFF the power, disconnect the power cord, and disconnect the gas supply.

2. Remove the cover from the power supply and remove the Nomex barrier from in front of the

power board.

3. Remove the rear endcap.

4. The power cord has a brown wire and a blue wire that connect to the power switch and a

green and yellow ground wire that connects to the heatsink.

Carefully pull the connector for the blue wire away from the power switch to disconnect it. You

can use needlenose pliers or a straight screwdriver to ease it out, if necessary.

Single phase

L

Brown

N

Blue

PE

Green/yellow

PMX30_OM_05.qxp:PMX30_OM_05 10/7/09 12:46 PM Page 5-17

Summary of Contents for Powermax30 AIR

Page 24: ...1 12 Hypertherm 11 08 SAFETY ...

Page 36: ...11 08 1a 12 Hypertherm SÉCURITÉ ...