Service Parts

2

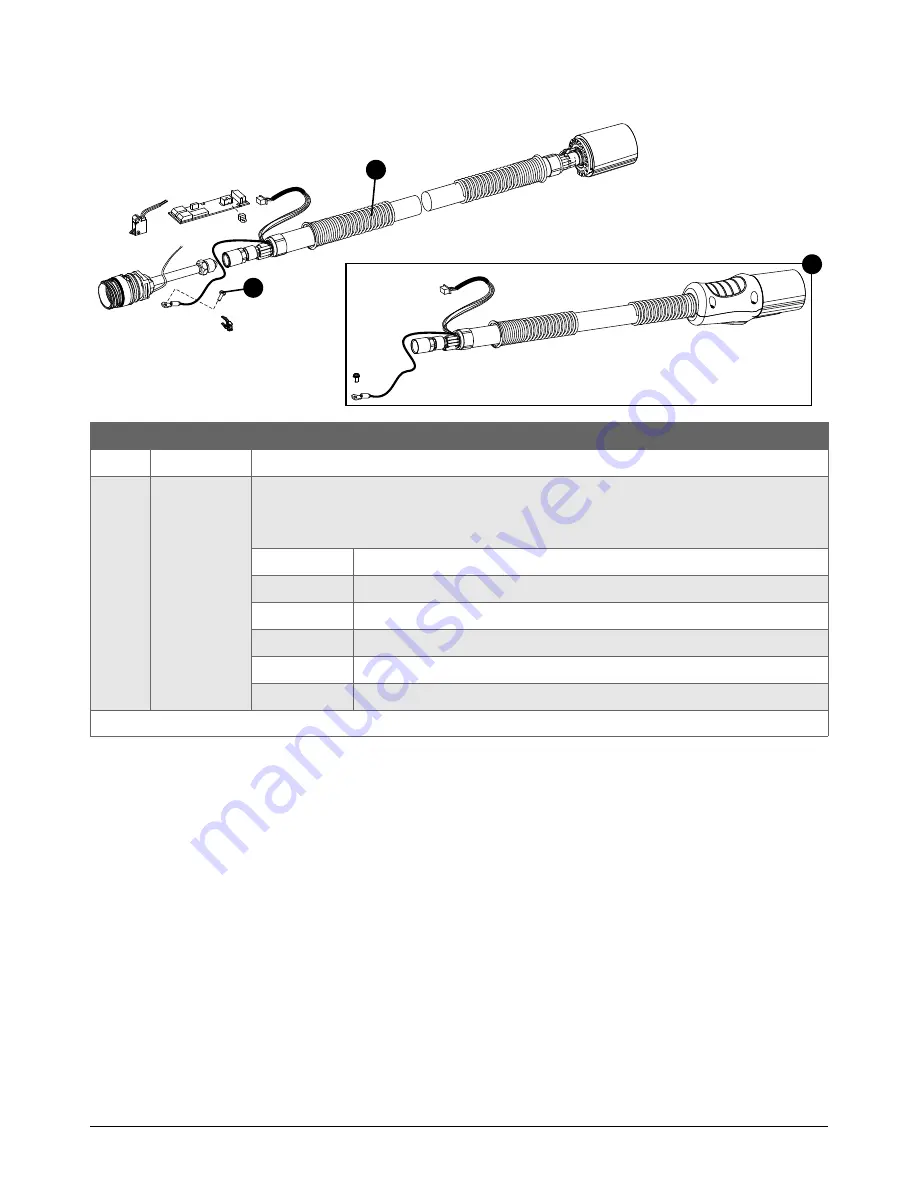

SmartSYNC

Service Parts and Procedures

810460

27

Mini machine and 180° robotic torch lead and terminal screw

Item

Part number

Description and kit contents

1

075903

Terminal screw (1/4 inch) for pilot arc wire

2

428901

428900

428903

Kit: Lead for mini machine and robotic torch, 4.6 m (15 foot)

Kit: Lead for mini machine and robotic torch, 7.6 m (25 foot)

Kit: Lead for mini machine and robotic torch, 15 m (50 foot)

229966

Lead for kit 428901, 4.6 m (15 foot)

229967

Lead for kit 428900, 7.6 m (25 foot)

229969

Lead for kit 428903,15 m (50 foot)

210735

Data plate: SmartSYNC torch (not shown)

210729

Label: SmartSYNC torch lead (not shown)

075903

Terminal screw (1/4 inch) for pilot arc wire*

* Can also be ordered separately as part number 075903 (quantity: 1).

2

1

2

Summary of Contents for SmartSYNC 059719

Page 1: ...SmartSYNC Torches Service Parts and Procedures Guide 810460 REVISION 0 ENGLISH ...

Page 10: ...10 810460 Service Parts and Procedures SmartSYNC ...

Page 12: ...Before You Begin 1 12 810460 Service Parts and Procedures SmartSYNC ...

Page 42: ...Prepare to Do the Part Replacement 3 42 810460 Service Parts and Procedures SmartSYNC ...

Page 62: ...Hand Torch Part Replacement Procedures 4 62 810460 Service Parts and Procedures SmartSYNC ...

Page 96: ...Torch Lead Replacement Procedures 7 96 810460 Service Parts and Procedures SmartSYNC ...

Page 98: ...Do a Check of the Torch Assembly 8 98 810460 Service Parts and Procedures SmartSYNC ...