5

© 2012 Installation and Reference Manual D0125 Rev. H

Section 1

— READ FIRST! — Important Safety Information

Site, Gate, Equipment and Regulatory Requirements

The gate moves freely in both directions. Never over-tighten a clutch or pressure relief valve to

compensate for a stiff gate.

The operator will be installed on the secured (non-public) side of the gate.

The operator will be properly electrically grounded and the intended supply voltage matches the

voltage label on the operator.

The gate operation controls have been mounted far enough away from the moving gate such

that users cannot touch the gate while operating the controls. All easily accessible controls must

have a security feature to prevent unauthorized use.

The operator controls will be located in line-of-sight to the gate. Radio controls and other remote

access controls must be connected only to the

Remote Open input.

Required external entrapment sensors will be installed. Be certain to carefully review the

instructions for placement, installation and adjustment of these external entrapment sensors.

External entrapment sensors must function to reverse the movement of the gate

in both

opening and closing directions.

If edge (contact) sensors are used, they are to be mounted

on the leading and trailing edges of the gate, as well as post mounted on the inside and outside

of the gate (See illustration on page 4). If photo eyes or other non-contact sensors are used,

they are to be mounted in locations most likely to guard against entrapment. A combination of

contact and non-contact sensors may be used, but all must be recognized components under

the UL 325 standard. See page 33 for details on the requirements.

If entrapment protection is provided by a continuous pressure actuation control, a placard

stating “WARNING” – “Moving Gate has the Potential of Inflicting Injury or Death - Do Not Start

Gate Unless Path is Clear” must be posted. Additionally, no other activation device shall be

connected and no automatic closing device, of any kind, shall be used.

The automatic operator is labeled as appropriate for both the type and UL usage class of the

gate.

NOTE:

SlideDriver 50VF2, 50VF2-EFO and 50VF3 sliding gate operators must be installed only

for Class III & IV applications.

Class I: Intended to serve single to four family residential uses

Class II: Multi-family use, or any application intended to serve the general public

Class III: Commercial applications

not

intended to serve the general public

Class IV: Highest security. Security personnel prevent unauthorized access

Sliding gate operators installed in Class III & IV applications do not have a speed restriction

and the secondary entrapment sensor requirement is met if the system is configured as

described for Class I & II use, or by the following alternative means, such as:

Employing the use of a 100dB buzzer which sounds at least 3 seconds before

the gate moves.

Employing the use of a constant hold-type push button control.

Summary of Contents for SlideDriver 50VF2

Page 2: ......

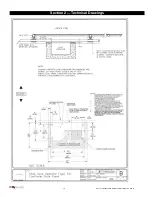

Page 28: ...14 2012 Installation and Reference Manual D0125 Rev H Section 2 Technical Drawings...

Page 29: ...15 2012 Installation and Reference Manual D0125 Rev H Section 2 Technical Drawings...

Page 36: ...22 2012 Installation and Reference Manual D0125 Rev H Section 3 Wiring Control Inputs...

Page 63: ...49 2012 Installation and Reference Manual D0125 Rev H Section 6 Internal Solenoid Lock Drawing...

Page 64: ...50 2012 Installation and Reference Manual D0125 Rev H Section 6 Internal Solenoid Lock Drawing...

Page 81: ...68 2012 Installation and Reference Manual D0125 Rev H...