52

© 2012 Installation and Reference Manual D0125 Rev. H

Section 7

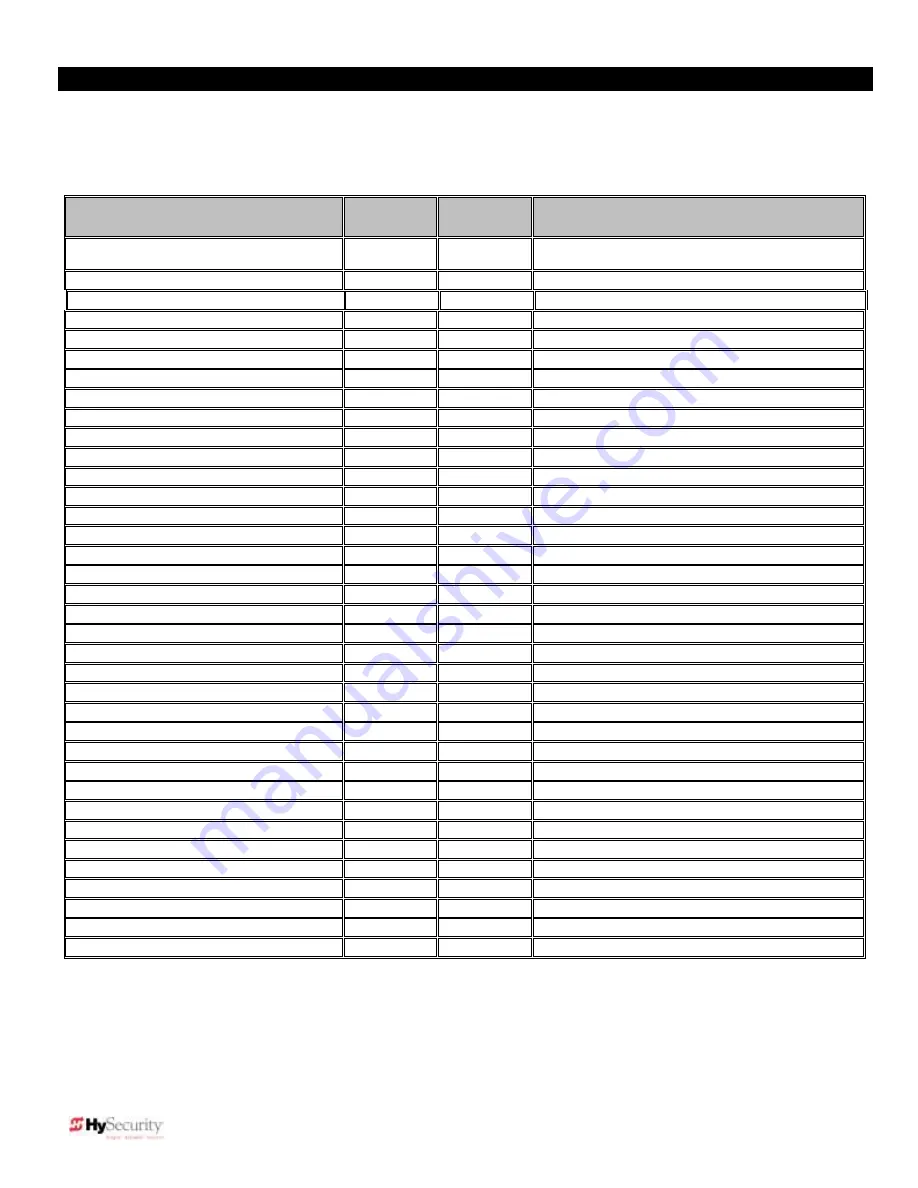

— STC Troubleshooting

The Smart Touch Controller (STC) includes many self diagnostics. Specific messages appear on the display and the

Audio Alert buzzer sounds distinctive chirps. Any Alerts, Faults or Errors are also logged into memory and date/time

stamped. For diagnostic purposes these messages can be retrieved with optional START software available from

HySecurity (see bottom of page 31). The following chart lists problem codes detected by the Smart Touch Controller.

Updates to this chart appear on HySecurity’s website at www.hysecurity.com

Error, Fault, or Alert Status

LCD

Display

Reads

Buzzer Chirp Sequence

Cannot respond due to tripped IES sensor or

operator is in entrapment mode

Entr

2 chirps/sec every 2 seconds while control input is

active

Safety Mode Alert

SAFE

2 chirps once when in Safety Mode

Low 24V Control Voltage Alert (AC or DC)

Lo24

N/A (display flashes 1 sec every 5 seconds)

Critical Low Power (AC or DC )

bAdP

1 chirp every 3s – controls disabled

Dead 24V Battery Alert – DC only

bat – dEAd

3 chirps upon any operating command

Gate Forced Open Alert

ALE1

2 pulses/sec for 30 seconds

Gate drift closed Alert

ALE2

2 pulses/sec for 10 seconds

Motor thermal overload Alert

ALE4

2 chirps/sec once every 15 seconds

Both Limits Tripped Alert

ALE5

2 chirps/sec every 15 seconds

Limits not released in 10 seconds

ALE6

2 chirps/sec every 15 seconds

Loop detector freq change alert

ALE7

2 chirps/sec every 15 seconds

Loop shorted to ground alert

ALE8

2 chirps/sec every 15 seconds

Loop open (disconnected) alert

ALE9

2 chirps/sec every 15 seconds

Loop detector comm. alert

AL10

2 chirps/sec every 15 seconds

Loop detector failed alert

AL11

2 chirps/sec every 15 seconds

Loop detector active >5 minutes

AL12

2 chirps/sec every 15 seconds

General I2C Comm. Buss failure

AL16

2 chirps/sec every 15 seconds

Bad 3V coin battery

AL17

2 chirps/sec every 15 seconds

False slow down signal

AL19

2 chirps/sec every 15 seconds

Lock Intrlk (Input #22) Blocks Open

AL20

2 chirps/sec every 15 seconds

VFD Error Alert

AL21

2 chirps/sec every 15 seconds

Dual/Seq. Gate communication lost

AL22

2 chirps/sec every 3 seconds

Maximum Run Fault

FAL1

1 chirp once every 15 seconds

Photo eye Fault (supervised)

FAL2

2 chirps/sec once per minute

Critical AC sag – bad supply wire

FAL3

2 chirps/sec once per minute

Open or Closed limit failed

FAL5

2 chirps/sec once per minute

Directional Motion Error

Err1

3 chirps/sec once per minute

Disconnected IES Error

Err2

3 chirps/sec once per minute

Serial comm. internal Error

Err3

3 chirps/sec once per minute or 3 on Cmd.

Serial comm. mast/slave Error

Err4

3 chirps/sec once per minute

STC-VFD Communications Error

Err6

3 chirps/sec once per minute

EEPROM Data Error (factory)

Err7

3 chirps/sec once per minute

EEPROM Data Error (installer)

Err8

3 chirps/sec once per minute

EEPROM Data Error (user menu)

Err9

3 chirps/sec once per minute

Open or Close slow down switch failed

Er10

3 chirps/sec once per minute

Memory Checksum Error

Fail

3 chirps/sec once per minute

NOTE:

The green LED near the “coin” battery on Smart Touch Controller is the “heartbeat” of the processor. This LED

always blinks at a steady pace which indicates normal operation.

Gate Speed:

The gate speed is determined by the size of the hydraulic operator’s pump and its actuator components. Just like a gear

box, this speed is not adjustableDo not attempt to slow a gate by changing a valve setting. If the speed of a gate must be changed,

contact your HySecurity distributor. Extremes in temperature usually does not affect the speed of the gate. HySecurity hydraulic gate

operators use a special fluid called

Uniflow

, which maintains a linear viscosity over a broad range of temperatures. HySecurity operators

are rated for service in ambient temperatures of -40°F to 158°F. If the speed of your operator is affected by temperature, verify that the

gate hardware is not impaired and check that the reservoir is filled with

Uniflow

. Consider adding a heater in extreme weather.

Summary of Contents for SlideDriver 50VF2

Page 2: ......

Page 28: ...14 2012 Installation and Reference Manual D0125 Rev H Section 2 Technical Drawings...

Page 29: ...15 2012 Installation and Reference Manual D0125 Rev H Section 2 Technical Drawings...

Page 36: ...22 2012 Installation and Reference Manual D0125 Rev H Section 3 Wiring Control Inputs...

Page 63: ...49 2012 Installation and Reference Manual D0125 Rev H Section 6 Internal Solenoid Lock Drawing...

Page 64: ...50 2012 Installation and Reference Manual D0125 Rev H Section 6 Internal Solenoid Lock Drawing...

Page 81: ...68 2012 Installation and Reference Manual D0125 Rev H...