55

© 2012 Installation and Reference Manual D0125 Rev. H

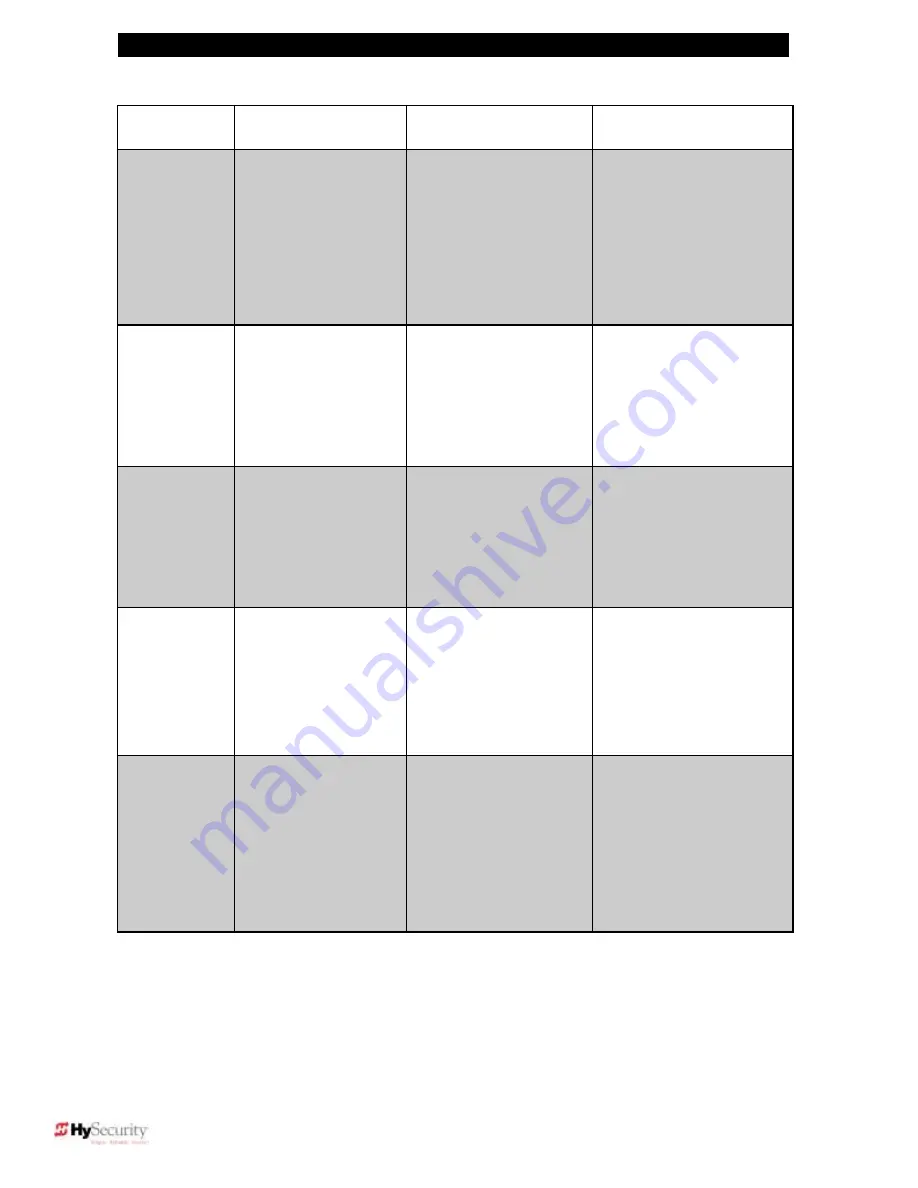

Fault Code

Meaning

Possible Cause

Solution

VFD DC bus voltage too

high

The operator’s AC input

voltage is too high or too

much noise exists on the

AC line.

Measure AC input voltage. If

it is too high, lower the

incoming voltage. Consult

with a qualified technician

and consider installing a

buck transformer to lower

the voltage. If noise is the

issue, consider an EMI filter

on the input lines.

VFD DC bus voltage too

low

The operator’s AC input

voltage is too low or the

wire size is too small for

the distance being

covered from the breaker

box to the operator.

Measure AC input voltage. If

it is too low, raise the

voltage level. Consult with a

qualified technician to learn

which options will raise the

voltage sufficiently to allow

for proper operator function.

Excessive power load

on VFD

Pressure Relief Valve is

set too high. This may

occur to compensate for a

binding gate or an

overweight gate. Brake

valves could also be too

tight

.

Check gate for binding

issues or an overweight

installation. Make sure brake

valves are set to mid-range

and the pressure relief valve

setting is about 1100psi or

less.

Excessive

instantaneous load on

VFD

NOTE:

Cannot reset the

fault code until 10

seconds elapse after

the fault occurs.

Pressure Relief Valve is

set too high. This may

occur to compensate for a

binding gate or an

overweight gate. Brake

valves could also be too

tight

.

Check gate for binding

issues or an overweight

installation. Make sure brake

valves are set to mid-range

and the pressure relief valve

setting is about 1100psi or

less.

or

Excessive heat in VFD

Lack of air ventilation

around VFD. Excessive

load on VFD.

Perform the same resolution

steps in

. And then,

check and clear any

constriction around the front

and back cooling vents on

the gray control box. Make

sure air ventilation pathways

are clear around the VFD

inside the control box.

Table 7.1

— VFD Fault Code Diagnostics

NOTE:

To clear a fault code, press the RESET key.

Summary of Contents for SlideDriver 50VF2

Page 2: ......

Page 28: ...14 2012 Installation and Reference Manual D0125 Rev H Section 2 Technical Drawings...

Page 29: ...15 2012 Installation and Reference Manual D0125 Rev H Section 2 Technical Drawings...

Page 36: ...22 2012 Installation and Reference Manual D0125 Rev H Section 3 Wiring Control Inputs...

Page 63: ...49 2012 Installation and Reference Manual D0125 Rev H Section 6 Internal Solenoid Lock Drawing...

Page 64: ...50 2012 Installation and Reference Manual D0125 Rev H Section 6 Internal Solenoid Lock Drawing...

Page 81: ...68 2012 Installation and Reference Manual D0125 Rev H...