DO NOT charge frozen battery. Battery can

explode. If frozen, warm the battery to at least

61°F (16°C).

ENVIRONMENTAL SAFETY/HAZARDOUS

MATERIALS AND PROPER DISPOSAL

Decommissioning is a controlled

process used to safely retire a piece of

equipment that is no longer serviceable.

If the equipment poses an unacceptable

and unrepairable safety risk due to wear or damage

or is no longer cost effective to maintain (beyond

life-cycle reliability) and is to be decommissioned

(demolition and dismantlement),be sure to follow

rules below.

DO NOT

pour waste or oil directly onto the

ground, down a drain or into any water source.

Contact your country's Department of Public

Works or recycling agency in your area and

arrange for proper disposal of any electrical

components, waste or oil associated with this

equipment.

When the life cycle of this equipment is over,

remove battery and bring to appropriate facility

for lead reclamation. Use safety precautions

when handling batteries that contain sulfuric

acid.

When the life cycle of this equipment is over, it

is recommended that the frame and all other

metal and plastic parts be sent to a recycling

center.

Metal and plastic recycling involves the collection

of metal and plastic from discarded products and

its transformation into raw materials to use in

manufacturing a new product.

Recyclers and manufacturers alike promote the

process of recycling metal and plastic. Using

a metal and plastic recycling center promotes

energy cost savings.

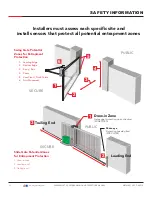

EXTERNAL ENTRAPMENT PROTECTION

SENSORS

Most HySecurity gate operators are equipped with

a Type A, Inherent Entrapment Sensor (IES). UL 325

Safety Standard compliance requires installation of

external entrapment protection sensors, number

of which, depends on entrapment hazards that

exist at each particular installation.

To comply with UL 325, the following external

sensors may be used:

Contact sensors, such as edge sensors

Non-contact sensors, such as photoelectric eyes

Site designer or installer can choose either

photoelectric eyes, edge sensors, or a combination

of these devices. Whatever devices are used,

protection in both opening and closing directions

of gate travel must be provided.

UL 325 Safety Standard for automatic sliding

gates specifically requires that edge sensors,

photoelectric eyes, or a combination of both

devices be installed to protect against pedestrian

entrapment in BOTH directions of gate travel and

wherever entrapment hazards exist.

PHOTOELECTRIC EYES:

One or more non-

contact sensor (photoelectric eyes) shall be

located where entrapment risk or obstruction

exists, such as perimeter reachable by a moving

gate.

Care shall be exercised to reduce the risk of

nuisance tripping, such as when a vehicle trips the

sensor while the gate is moving.

CAUTION

A contact or non-contact sensor is also required

to protect against possible entrapment if gate

opens to a position less than 16 inches from

any object, such as a post or wall.

SAFETY INFORMATION

15

| www.hysecurity.com

SWINGSMART DC PROGRAMMING AND OPERATIONS MANUAL

MX3640-01 REV. D ©2018