Examples of conditions which affect IES sensitivity

include:

Gate design

- For long and/or solid gates in windy

environments, large variations in motor current

may occur. In these types of scenarios, you may

want to use a higher (less sensitive) IES setting.

Gate condition

- If the gate environment is near

salty sea air, rusty hinges might impede gate travel

over time. Additionally, gates that are hit and bent

may have very stiff areas during travel that cause a

large variation in motor current. For these issues,

you may want to use a higher (less sensitive) IES

setting until repairs are made.

Gate maintenance

- Gate hinges will deteriorate

and begin to fail over time. In poorly maintained

gate areas, the chance for false IES trips is higher.

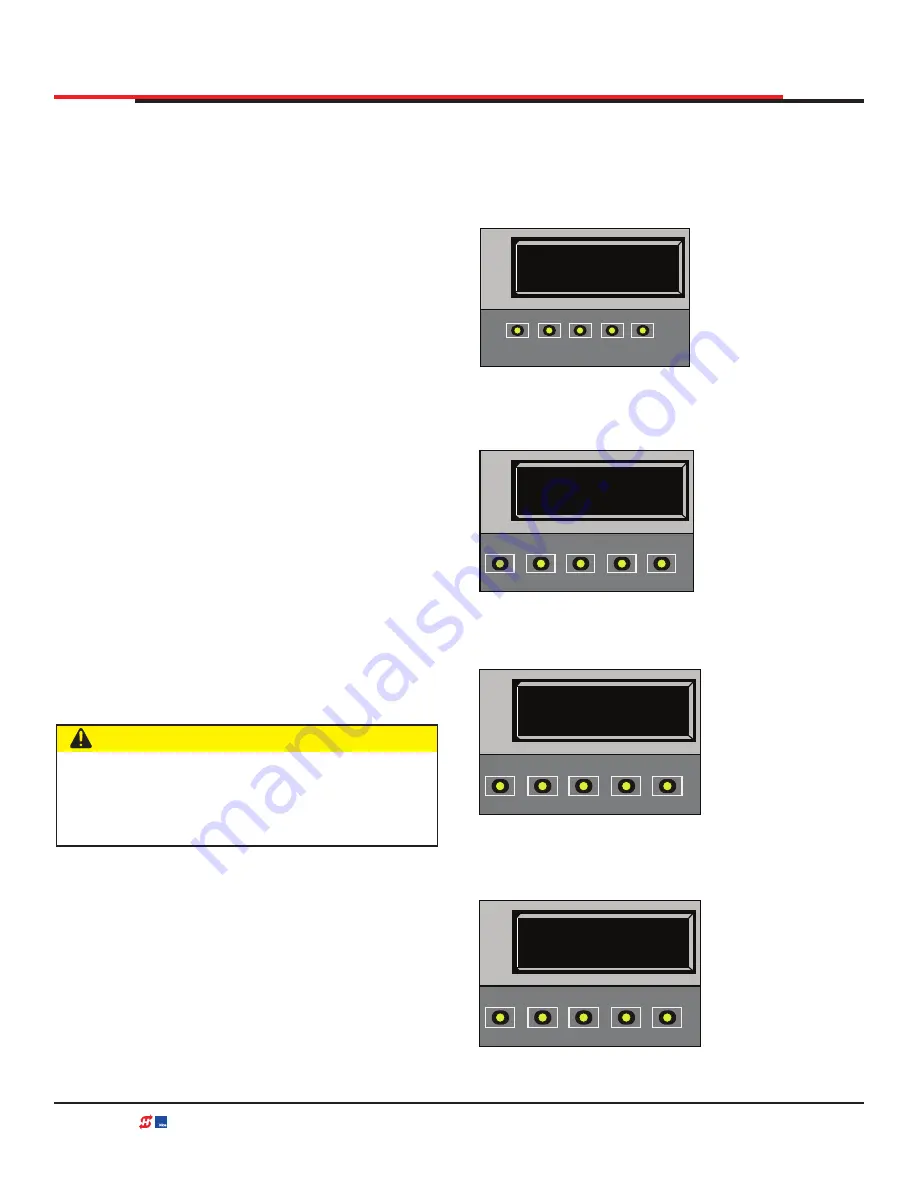

To adjust the IES sensitivity, take the following

1.

At a gate status display, press the MENU button

twice. The CLOSE TIMER display appears.

2.

Simultaneously, press the OPEN and RESET

buttons to enter the Installer Menu. Release

the buttons and the LEARN LIMITS display

appears.

3.

Press NEXT until the IES SENSITIVITY display

appears. The factory default setting is 2.

4.

Use the SELECT and NEXT buttons to navigate

and change the number on the display.

5.

To exit the Installer Menu, press the MENU

button. The gate status appears in the display

indicating you have returned to Run Mode.

CAUTION

Avoid setting the IES sensitivity to a fixed level

(7 - 9 setting). The high motor current required

for the IES to trip could cause severe injury or

death to people caught in the moving gate.

If IES trips occur, SAFE MODE or ENTRAPMENT

MODE will appear on the display. For more

information about troubleshooting,

refer to

"Smart DC Controller - Troubleshooting" on page

Figure 46. Adjusting IES Sensitivity

CT 0 (OFF)

CLOSE TIMER

OPEN

CLOSE

STOP

MENU

RESET

PREV

NEXT

SELECT

HYSECURITY

GATE CLOSED

OPEN

CLOSE

STOP

MENU

RESET

PREV

NEXT

SELECT

1. Start at a gate

status display.

2. To access the

User Menu,

press the MENU

button twice.

3. Access the

Installer Menu, by

simultaneously,

pressing the

OPEN and

RESET

buttons.

4. Use NEXT to

navigate to the

menu display.

Change the

setting using the

SELECT and

NEXT buttons.

LL 0 (OFF)

LEARN LIMIT

OPEN

CLOSE

STOP

MENU

RESET

PREV

NEXT

SELECT

SE 2

IES SENSITIVITY

OPEN

CLOSE

STOP

MENU

RESET

PREV

NEXT

SELECT

DISPLAY AND MENU OPTIONS

81

| www.hysecurity.com

SWINGSMART DC PROGRAMMING AND OPERATIONS MANUAL

MX3640-01 REV. D ©2018