MAINTENANCE

85

Pin forks

are fastened to the carriage with large fork pins.

A lock pin for each fork fits into the top carriage bar and a

slot in the fork. These lock pins hold the fork in position.

See FIGURE 19. Adjust the forks as far apart as possible

for maximum support of the load. Make sure the lock pin is

engaged in the carriage bar and the fork. The fork must be

locked into position after the adjustment is made.

Forks, Removal And Installation

A fork can be removed from the carriage for replacement

of the fork or other maintenance. See FIGURE 19. and

FIGURE 20.

WARNING

Do not try to move a fork without a lifting device. Each

fork for these lift trucks can weigh 66 kg to 183 kg

(145 to 402 lb) for a hook fork and 128 to 226 kg (281

to 498 lb) for a pin fork.

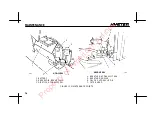

FIGURE 20. REMOVE A HOOK FORK

1

3

2

1. CARRIAGE BARS

2. HOOK FORK

3. BLOCKS

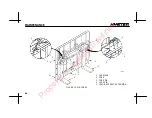

Hook Fork (Removal).

Slide a hook fork to the fork re-

moval notch on the carriage. See FIGURE 21. Lower the

fork onto blocks so that the bottom hook of the fork moves

through the fork removal notch. See FIGURE 21. Lower

the carriage further so that the top hook of the fork is dis-

engaged from the top carriage bar. Move the carriage

away from the fork, or use a lifting device to move the fork

away from the carriage.

Hook Fork (Installation).

Move the fork and carriage so

that the top hook on the fork can engage the upper car-

Property of American Airlines