CLEAN AND INSPECT

WARNING

Cleaning solvents can be flammable and toxic and

can cause skin irritation. When using cleaning

solvents, always follow the recommendations of

the manufacturer.

WARNING

Compressed air can move particles so that they

cause injury to the user or to other personnel.

Make sure that the path of the compressed air is

away from all personnel. Wear protective goggles

or a face shield to prevent injury to the eyes.

Clean and inspect following parts of reduction gear

assembly:

• Tapered roller bearings

- Inspect cup, cone, rollers, and cage of all ta-

pered roller bearings in assembly. If bearings

show signs of wear, cracks, or damage, re-

place with new bearing.

• Ring gear - Inspect ring gear for wear or

damage. If gear is worn or damaged it must

be replaced.

• Wheel hub and wheel hub support - In-

spect wheel hub and wheel hub support for

wear or damage. Parts that are damaged

must be replaced.

• Planetary carrier and parts - Inspect all

parts of planetary carrier for wear or dam-

age. Parts that are damaged must be re-

placed. If gears are replaced, new needle

bearings must be used. If any planet gear

needs to be replaced, all planet gears should

be replaced.

ASSEMBLE

1.

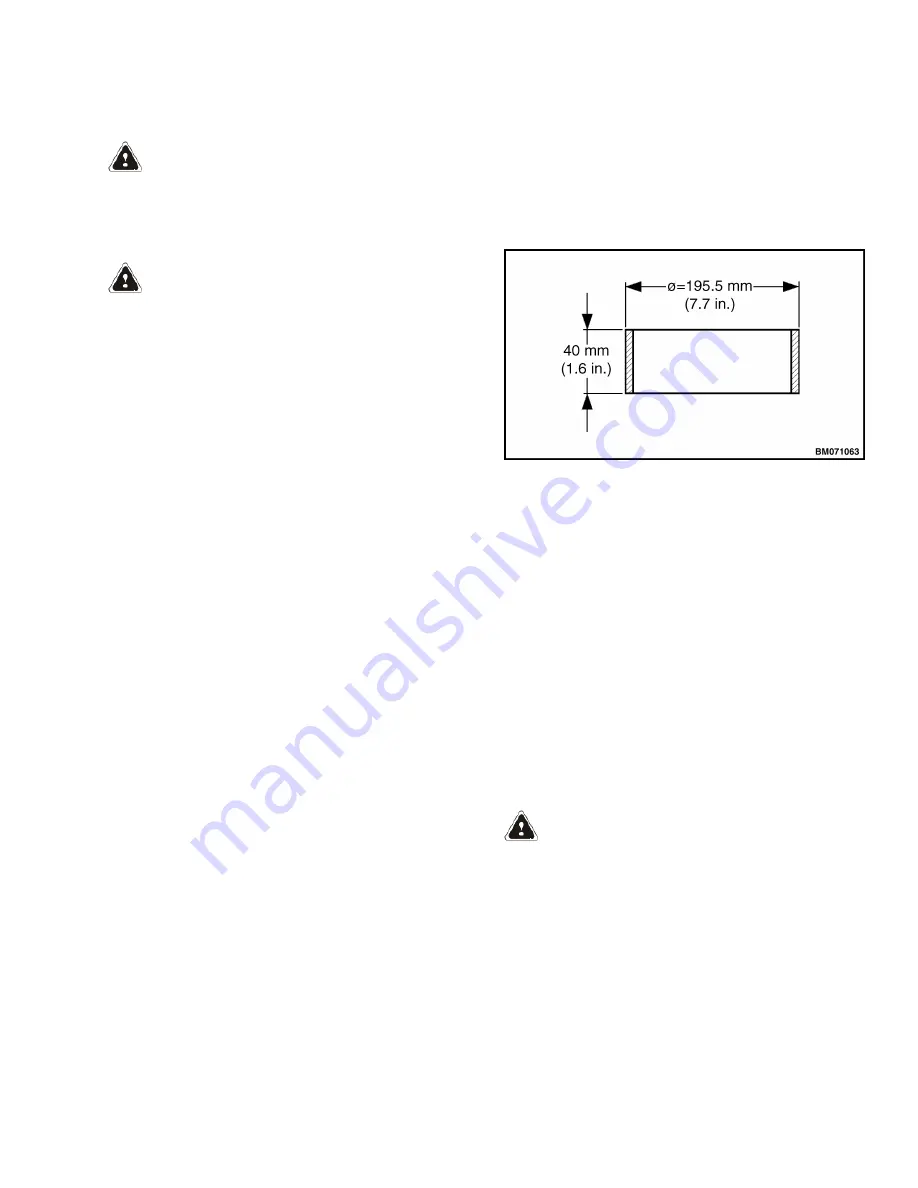

For lift truck models S4.0, 4.5, 5.5FT, S5.5FTS

(S80, 100, 120FT; S80, 100FTBCS; S120FTS;

S120FTPRS) (H004, J004), support wheel hub.

It is recommended to use a steel ring (spacer)

with dimensions as shown in Figure 19, but

blocks may be used as well as long as there is

enough clearance to install wheel stud com-

pletely. Support wheel hub flange where wheel

stud is to be installed with an over sized socket

or spacer (as shown in Figure 20) to prevent

warping wheel hub flange.

For lift truck models H4.0FT5/FT6; H4.5FTS5,

H4.5FT6, H5.0-5.5FT (H80, 90, 100, 110, 120FT)

(R005, S005, U005), place wheel hub as shown in

Figure 21.

Figure 19. Steel Ring

2.

For lift truck models S4.0, 4.5, 5.5FT, S5.5FTS

(S80, 100, 120FT; S80, 100FTBCS; S120FTS;

S120FTPRS) (H004, J004), using a press or

hammer, install wheel studs. See Figure 20.

For lift truck models H4.0FT5/FT6; H4.5FTS5,

H4.5FT6, H5.0-5.5FT (H80, 90, 100, 110, 120FT)

(R005, S005, U005) apply a coat of Loctite

2760

TM

or Loctite 277

TM

on to threads of wheel

stud ends threading into wheel hub and tighten

wheel studs to 245 to 300 N•m (181 to 221

lbf ft). See Figure 21.

3.

Using appropriate driver tool install new seal

on to wheel bearing support. See Figure 22.

WARNING

Hot parts. Wear protective clothing and gloves to

prevent burns.

4.

Place wheel bearing support on a flat surface.

Heat a new inboard bearing cone to 80 to

90°C (176 to 194°F). Using appropriate driver

tool install inboard bearing cone on to wheel

bearing support. Once inboard bearing cone is

cool, lubricate with multipurpose grease.

1400 SRM 1582

Reduction Gear Assembly

13