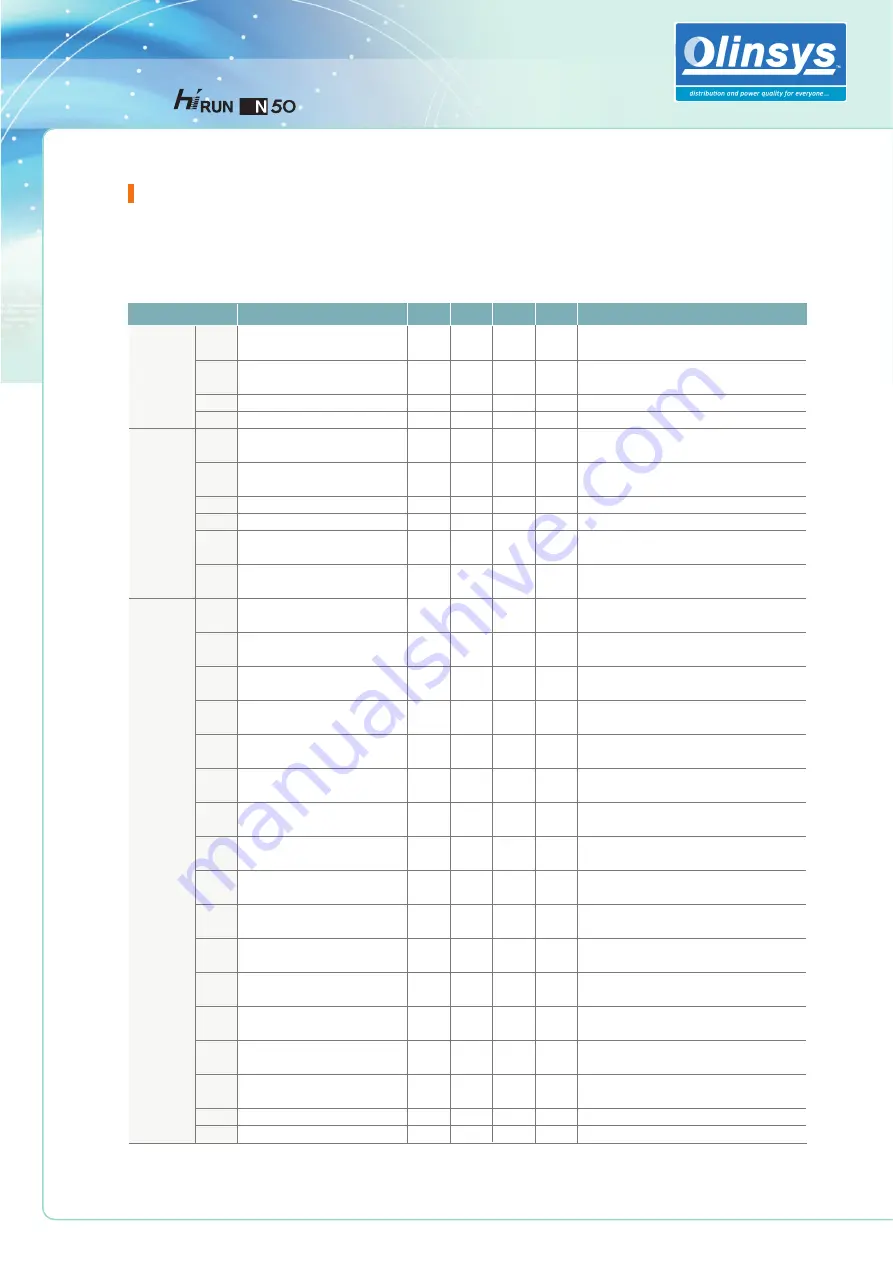

Function List

HYUNDAI INVERTER

Expanded Function A Mode

Function code

Name

Initial value Minimum value Maximum value

Unit

Code description

A01

A02

A05

A06

A07

A08

A09

A10

A11

A12

A13

A14

A15

A16

A17

A18

A19

A20

A21

A22

A23

A24

A25

A26

A27

A03

A04

0

0

0

0

3

2

-

-

0.00

0.00

A04

Hz

0.00

0.00

A04

Hz

0.0

100.0

0.0

0.0

100.0

100.0

%

%

0

4

5.00

10.00

15.00

20.0

0

30.00

40.0

0

50.0

0

60.0

0

0.00

0.00

0.00

0.00

0.00

0.00

0.00

1

8

A04

A04

A04

A04

A04

A04

A04

A04

A04

A04

A04

A04

A04

A04

A04

-

-

Hz

Hz

Hz

Hz

Hz

Hz

Hz

Hz

Hz

Hz

Hz

Hz

Hz

Hz

Hz

0

1

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.00

0.50

0

0.50

0

60.00

60.00

0.00

A03

A04

400.0

Hz

Hz

10.00

2

Hz

-

0: main unit volume, 1: control terminal,

2: standard operator, 3: remote operator (communication)

0: standard operator, 1: control terminal,

2: remote operator (communication)

0~maximum frequency (A04)

A03~400 Hz

0.0~400 Hz (by 0.01 Hz),

start frequency at 0 V, 4 mA input

0.0~400 Hz (by 0.01 Hz)

end frequency at 10 V, 20 mA input

Start rate for the analog input

End rate for the analog input

0: start at start frequency

1: start at 0 Hz

1~8 times,

analog input filter sampling count

0.00~400.0 Hz (by 0.01 Hz)

0.00~400.0 Hz (by 0.01 Hz)

0.00~400.0 Hz (by 0.01 Hz)

0.00~400.0 Hz (by 0.01 Hz)

0.00~400.0 Hz (by 0.01 Hz)

0.00~400.0 Hz (by 0.01 Hz)

0.00~400.0 Hz (by 0.01 Hz)

0.00~400.0 Hz (by 0.01 Hz)

0.00~400.0 Hz (by 0.01 Hz)

0.00~400.0 Hz (by 0.01 Hz)

0.00~400.0 Hz (by 0.01 Hz)

0.00~400.0 Hz (by 0.01 Hz)

0.00~400.0 Hz (by 0.01 Hz)

0.00~400.0 Hz (by 0.01 Hz)

0.00~400.0 Hz (by 0.01 Hz)

0.5~10.00 Hz (by 0.01 Hz)

0: free-run, 1: deceleration stop, 2: DC braking

Frequency commanding

RUN commanding

Base frequency setting

Maximum frequency setting

External frequency setting start

External frequency setting end

External frequency start rate setting

External frequency end rate setting

External frequency start pattern setting

External frequency sampling setting

Multispeed frequency 1 setting

(1st, 2nd motor)

Multispeed frequency 2 setting

(1st, 2nd motor)

Multispeed frequency 3 setting

(1st, 2nd motor)

Multispeed frequency 4 setting

(1st, 2nd motor)

Multispeed frequency 5 setting

(1st, 2nd motor)

Multispeed frequency 6 setting

(1st, 2nd motor)

Multispeed frequency 7 setting

(1st, 2nd motor)

Multispeed frequency 8 setting

(1st, 2nd motor)

Multispeed frequency 9 setting

(1st, 2nd motor)

Multispeed frequency 10 setting

(1st, 2nd motor)

Multispeed frequency 11 setting

(1st, 2nd motor)

Multispeed frequency 12 setting

(1st, 2nd motor)

Multispeed frequency 13 setting

(1st, 2nd motor)

Multispeed frequency 14 setting

(1st, 2nd motor)

Multispeed frequency 15 setting

(1st, 2nd motor)

Jog frequency setting

Jog stop operation selection

Basic

setting

External

frequency

setting

Multi

-

stage

speed

frequency

setting

Summary of Contents for HiRun N50 Series

Page 1: ......