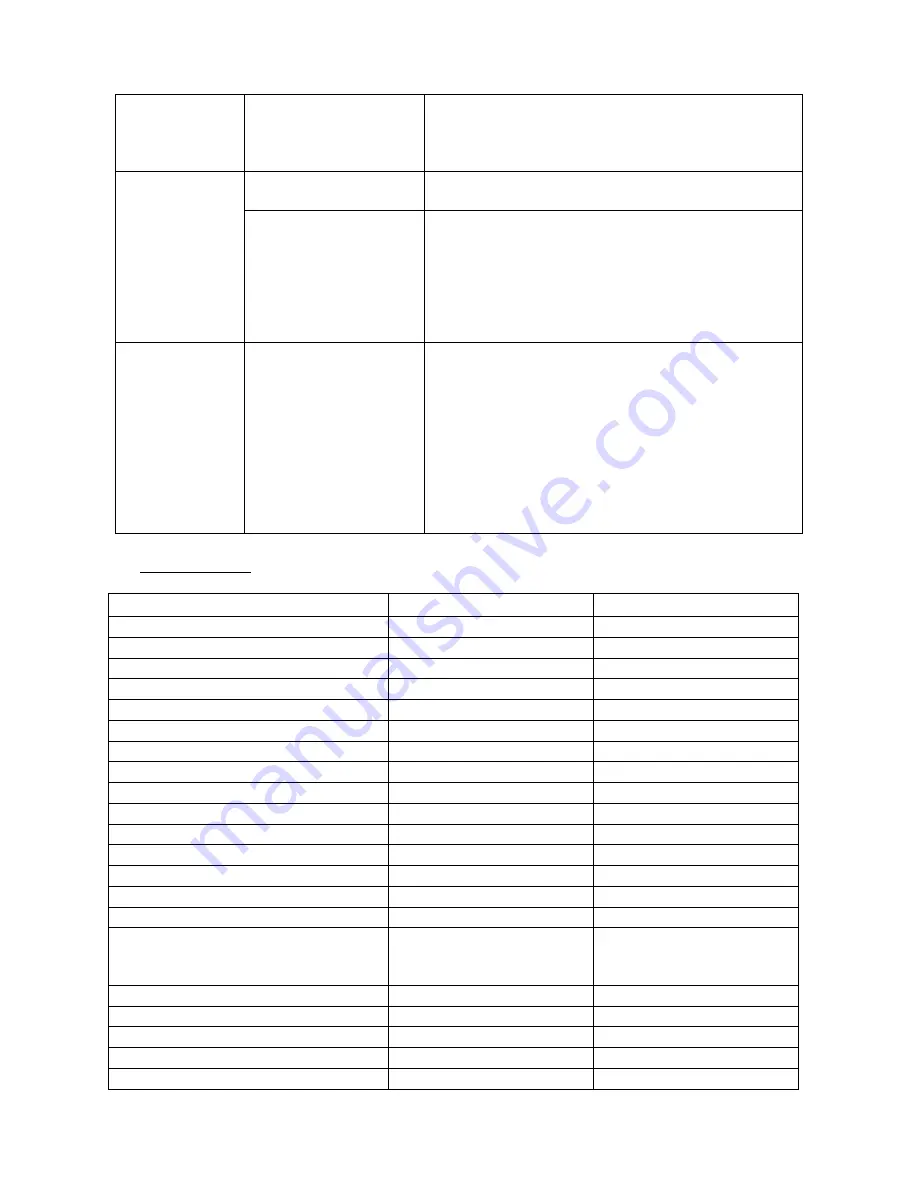

The compressor

does not reach

maximum

pressure.

Compressor head gasket

broken of faulty valve.

Stop the compressor and contact your dealer.

Compressor

doesn’t seem to

provide as much

air it did when

new and/or the

compressor cuts

off within a much

shorter time

period.

The pressure switch

needs adjusting.

Stop the compressor and contact your dealer.

The tank is full of water

due to condensation.

Open the ball valve and release the pressure.

Open the drain valve and release the water within the

tank.

The motor pump

unit does not

stop when the

tank pressure

reaches its

maximum

working pressure

(8 Bar/116PSi)

and the safety

valve vents air

Pressure switch defective

or needs adjusting.

Stop the compressor immediately and contact your

dealer.

7.

SPECIFICATIONS

Model

HY0808

HY0816

Voltage - V

230

230

Number of phases

1

1

Frequency – Hz

50

50

Connection method/Cable length m

3 pin plug - BS1363A/1.4

3 pin plug - BS1363A/1.4

Motor power hp/kw

0.75/0.56

0.75/0.56

Rated Speed (motor) – RPM

1430

1430

Cubic Foot per Minute @ 6.2 Bar

2.4

2.4

Maximum Pressure - PSi/Bar

145/10

145/10

Cut-out Pressure - PSi/Bar

128/8.8

128/8.8

Cut-inPressure - PSi/Bar

87/6

87/6

Tank Capacity - L

8

2 x 8

Free air delivery - CFM - L/min

2.4/68

2.4/68

Displacment - CFM/L/min

3.1/73

3.1/73

Displacement @ 40 psi L/min

55

55

Displacement @ 90 psi L/min

32

32

Air Outlet

Machine - Male 3/8" tapered

quick release euro/Hose -

Male 3/8" euro coupling

Machine - Male 3/8" tapered

quick release euro/Hose -

Male 3/8" euro coupling

Output pressure regulation type

Adjustable

Adjustable

Drive type

Direct

Direct

Overall Unit Dimensions L x W x H mm

490 x 405 x 390

490 x 400 x 530

Net Weight - kg

17.3

23.2

Tank material

Rolled steel

Rolled steel

Page 13

Ver 2

Summary of Contents for HY0808

Page 1: ......