4. PREPARATION BEFORE USE

The machine is shipped without oil - You MUST add oil before using this machine.

4.1.

Oil type – SAE15W40.

4.2.

Adding oil.

4.2.1.

Place the generator on a flat, level surface.

4.2.2.

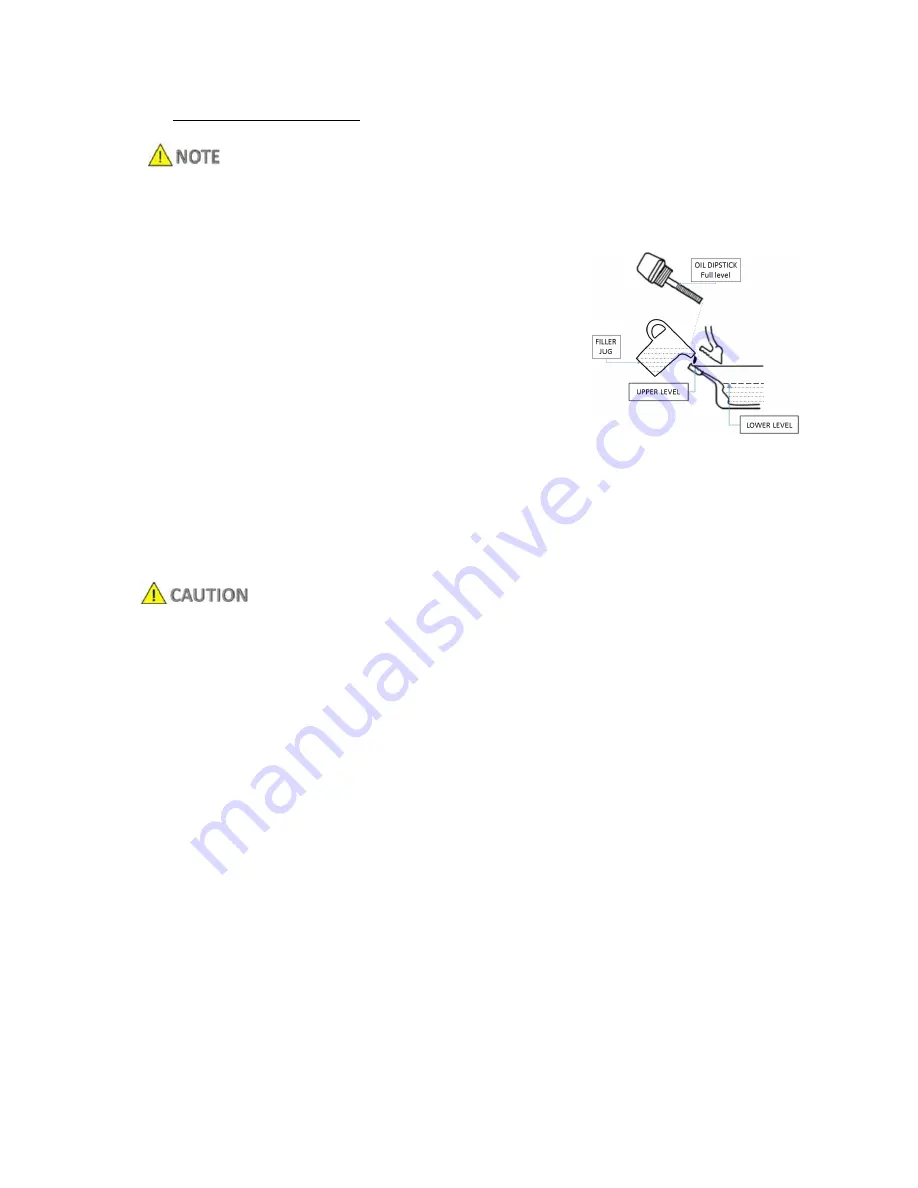

Clean area around oil filler and

remove oil cap and

dipstick. Wipe the dipstick clean.

4.2.3.

Slowly fill the engine with oil through the oil

filler until it reaches the upper thread of the

filler hole or to the full mark on the dipstick.

4.2.4.

Stop filling occasionally to check oil level. DO

NOT over fill.

4.2.5.

Refit the oil filler cap and make sure the cap

is

tightened.

4.2.6.

You MUST check engine oil level before starting every session.

4.3.

Fuel type Unleaded Petrol.

4.4.

Adding fuel.

Do not overfill the fuel tank you MUST allow space for fuel expansion. If the fuel tank is

overfilled, fuel can overflow onto a HOT engine and cause FIRE and/or EXPLOSION. If fuel

does spill, wait until it evaporates before starting engine. Check fuel lines, tank, cap and

fittings frequently for cracks or leaks. Replace as required.

4.4.1.

DO NOT light cigarettes or smoke when filling the fuel tank. Fuel is

highly FLAMMABLE and it

'

s vapo

u

rs are EXPLOSIVE.

4.4.2.

NEVER fill fuel tank when engine is running or hot. Turn generator engine OFF

and allow engine to cool entirely before filling fuel tank.

4.4.3.

Avoid spilling petrol on

to

HOT engine.

4.4.4.

Keep fuel away from sparks, open flames, pilot lights, heat, and other source

s

of ignition.

4.4.5.

D

O NOT

mix oil with

petrol

.

4.4.6.

Once fueling has finished refit the fuel cap and fully tighten. Wipe up any

spilled fuel before starting machine.

Page 11

Ver 2 - December 2016

Summary of Contents for HY10000LEK-2

Page 2: ...Page 2 Ver 2 December 2016 ...

Page 26: ...Page 26 Ver 2 December 2016 ...

Page 27: ...Page 27 Ver 2 December 2016 ...