1-17

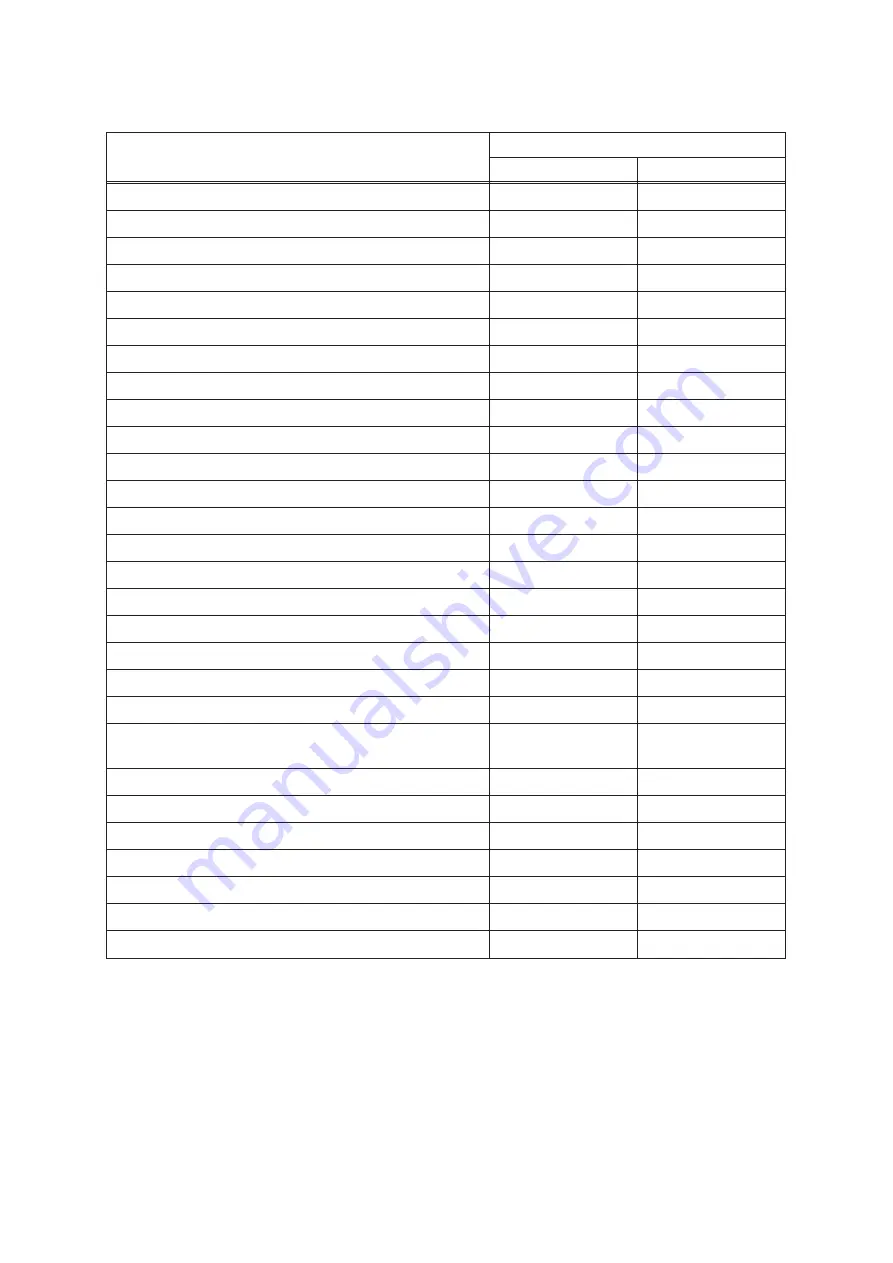

R250LC-9 HIGH WALKER

R250LC-9 HIGH WALKER

Upperstructure assembly

Main frame weld assembly

Engine assembly

Main pump assembly

Main control valve assembly

Swing motor assembly

Hydraulic oil tank assembly

Fuel tank assembly

Counterweight

Cab assembly

Lower chassis assembly

Track frame weld assembly

Swing bearing

Travel motor assembly

Turning joint

Track recoil spring

Idler

Carrier roller

Track roller

Track-chain assembly (600 mm standard triple grouser shoe)

Front attachment assembly (5.85 m boom, 3.05 m arm,

1.08 m

3

SAE heaped bucket)

5.85 m boom assembly

3.05 m arm assembly

1.08 m

3

SAE heaped bucket

Boom cylinder assembly

Arm cylinder assembly

Bucket cylinder assembly

Bucket control rod assembly

Item

10500

2360

560

136

220

345

220

200

4600

310

12000

5280

360

276

53

200

250

55

55

1860

4950

1940

1020

910

240

340

220

110

23150

5200

1240

300

485

760

485

440

10140

680

26460

11640

800

608

117

440

550

120

120

4100

10910

4280

2250

2010

530

750

490

240

kg

lb

R250LC-9 HIGH WALKER

2)

2)