New R-Line Refuse Collection Micro

User Manual RCM10

47

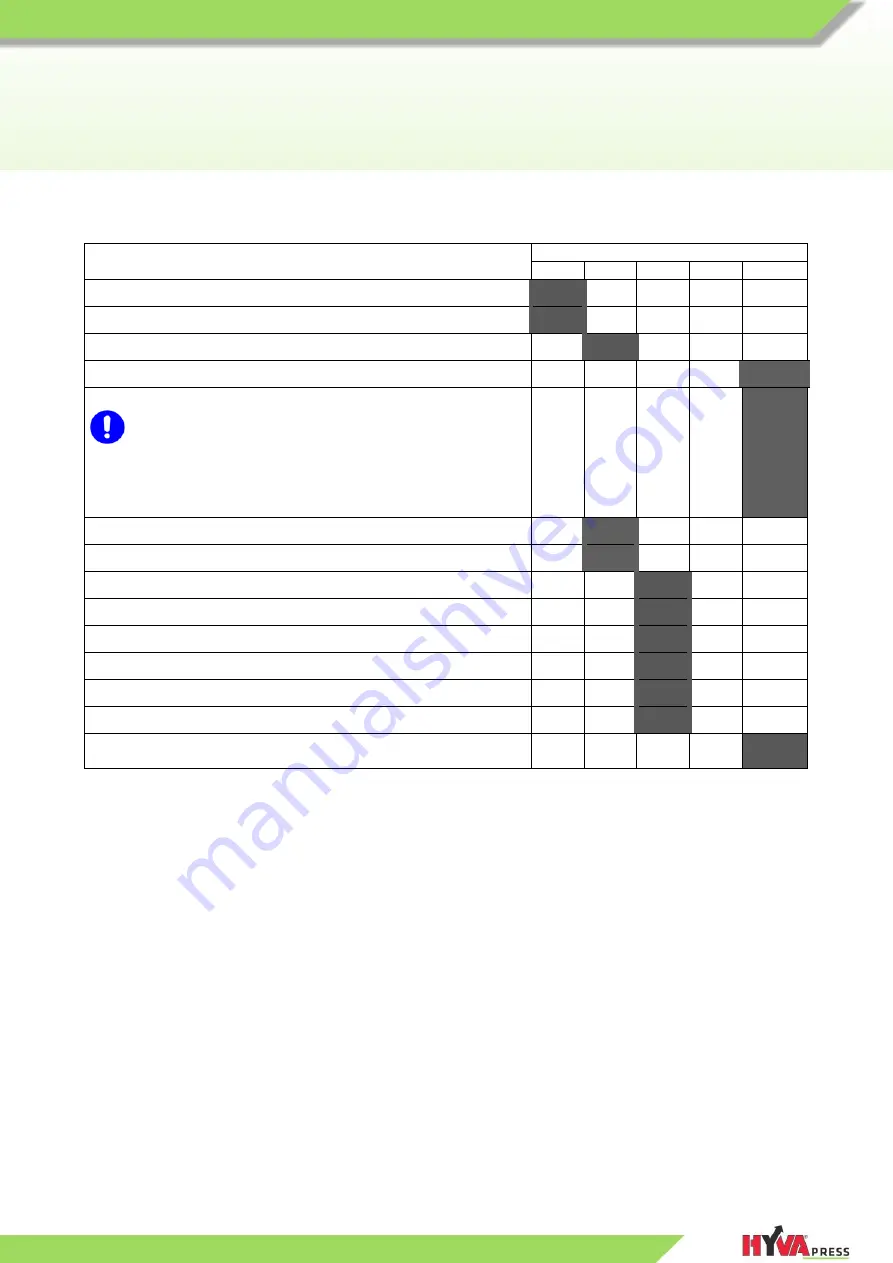

4.10

Preventive and recurrent maintenance programme

INTERVENTION

FREQUENCY OF CHECKS (h)

8

40

250

500

1000

Clean the compacting shovel.

Clean the rear edge safety latch movement zone.

Check/refill the hydraulic oil in the tank.

Change the hydraulic oil.

Replace the unloading filter.

WARNING

Regardless of the frequency indicated to the side,

the filter must also be replaced whenever the

indicator on the filter itself is found to be in the RED

sector.

Check the state of the flexible tubes.

Check the state of the hydraulic cylinders.

Perform a general inspection of the machine.

Grease the hinge points.

Check the pressure in the hydraulic system.

Check the state of the electrical cables.

Check the electric boxes.

Check the electrical connections.

Check the proper tightening of all the equipotential connection

points.

Table 5-4

The following tables summarize the routine and extraordinary maintenance program recommended for the first

seven operational years of the machine.1200 working hours per year are considered.