22

11. CATALOGUE NUMBERS

SIGMA-MD MONITOR RELAY

Ground Fault Relay & Neutral Grounding Resistor Monitor

(Special

Order:

SIGMA-MD)

GFU-AM1

Analog Meter, 3 ½ in. 0-1 mA with Scale 0-100%

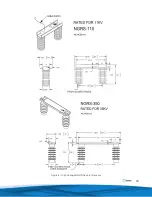

NGRS-XX RESISTOR SENSOR

Resistor Sensor

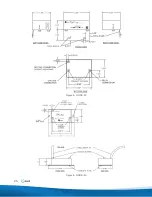

T2A ZERO SEQUENCE CURRENT SENSOR

With a 2 inch (5.08 cm) window.

T3A ZERO SEQUENCE CURRENT SENSOR

With a 3 inch (7.62 cm) window.

T6A ZERO SEQUENCE CURRENT SENSOR

With a 6 inch (15.24 cm) window.

T9A ZERO SEQUENCE CURRENT SENSOR

With a 9 inch (22.86 cm) window.

APPENDIX A

High-pot and dielectric testing of the system.

As the SIGMA-MD monitor relay, NGRS-XX resistor sensor and TxA type zero sequence current sensor have

undergone and passed high-pot testing at the factory, field testing of the relay is unnecessary and may damage

these components. For any high-pot tests or dielectric withstand tests on the system conducted in the field, the

SIGMA-MD monitor relay, NGRS-XX resistor sensor and TxA type ZSCS must be prepared as described below to

avoid damaging this equipment.

1. Ensure all control circuits are disconnected and insulated.

2. Disconnect the conductor on terminal R of the NGRS-XX resistor sensor from the SIGMA-MD monitor relay and

ensure the conductor is insulated.

3. Disconnected the conductor on terminal G of the NGRS-XX resistor sensor from ground and ensure the

conductor is insulated.

4. Disconnected the conductors between the X1 and X2 terminals of the TxA type ZSCS and the SIGMA-MD monitor

relay and ensure these conductors are insulated.

5. Disconnect the control power leads from the SIGMA-MD monitor relay and ensure these conductors are insulated.

6. Connect short conductors between the L, N and G terminals of the SIGMA-MD monitor relay ensuring that the G

terminal remains connected to ground.

7. Perform the high-pot or dielectric withstand tests required.

8. Reconnect the conductors between the X1 and X2 terminals of the TxA type ZSCS and the SIGMA-MD

monitor relay.

9. Reconnect the conductor between terminal G of the NGRS-XX resistor sensor and the appropriate terminal on the

SIGMA-MD monitor relay. Refer to Figure 2.

10. Reconnect the conductor from the G terminal on the NGRS-XX resistor sensor to ground.

11. Remove the conductors added between the L, N and G terminals of the

SIGMA-MD monitor relay ensuring that the G terminal remains connected to ground.

12. Reconnect the conductor from the R terminal of the NGRS-XX resistor sensor to the appropriate terminal of the

SIGMA-MD monitor relay. Refer to Figure 2.

13. Reconnect and control circuits which were disconnected in step 1.

14. Reconnect the control power to the L and N terminals of the SIGMA-MD monitor relay.