CABLINE-CX II PLUG With Cover Assembly Manual

Document No.

ASM-17008

4

/

16

Confidential C

5. 作業手順 (Work procedures):

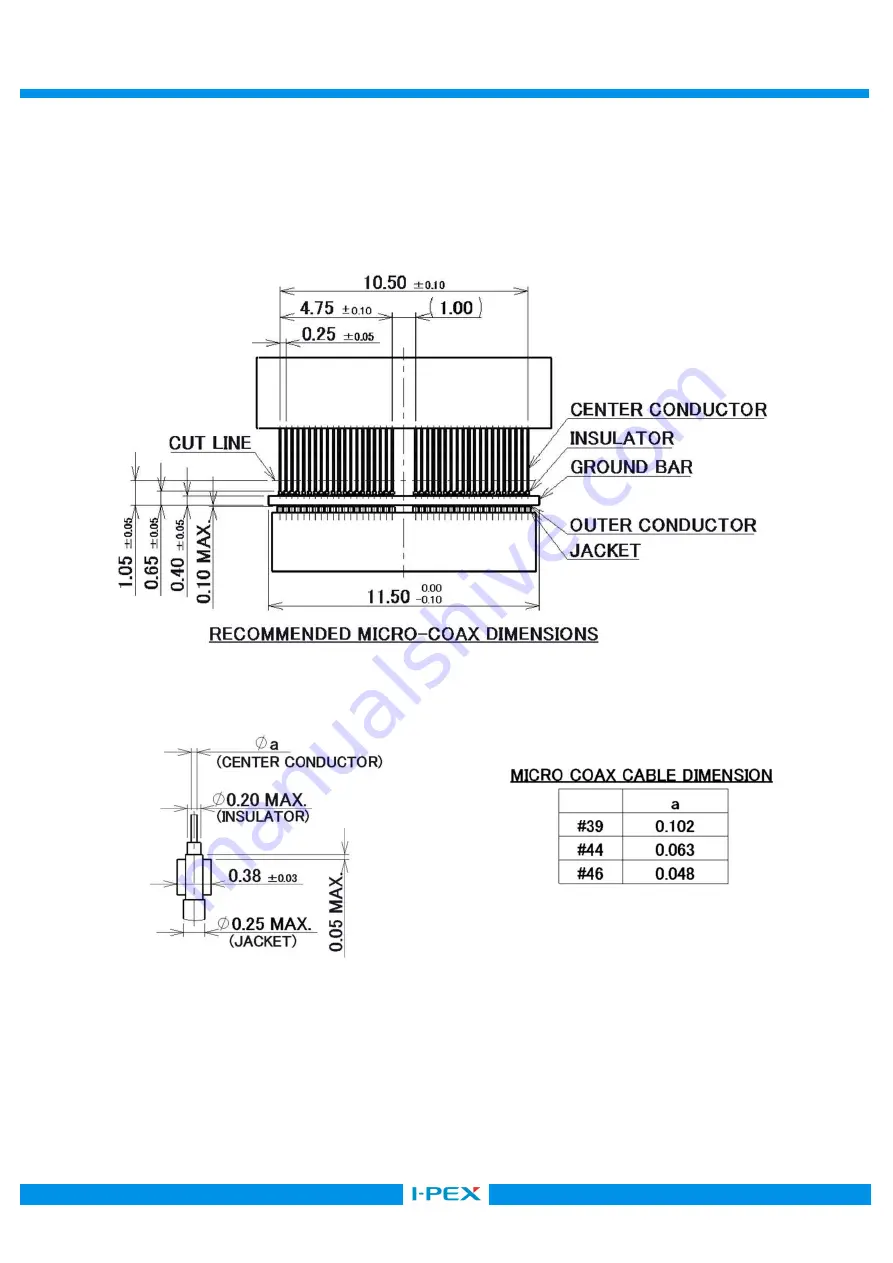

5-1. 芯線の半田付け (Soldering of center-conductor)

①まず適合ケーブルの端末処理形状を下図の様にして下さい。

The cables have to be fabricated as shown below in advance of soldering.

【Micro coax cable】

Unit: mm

Micro coax cable #39 :

Not recommended for high speed signal transfer