CABLINE-CAL Assembly Manual

Document No.

ASM-17003

6

/

13

Confidential C

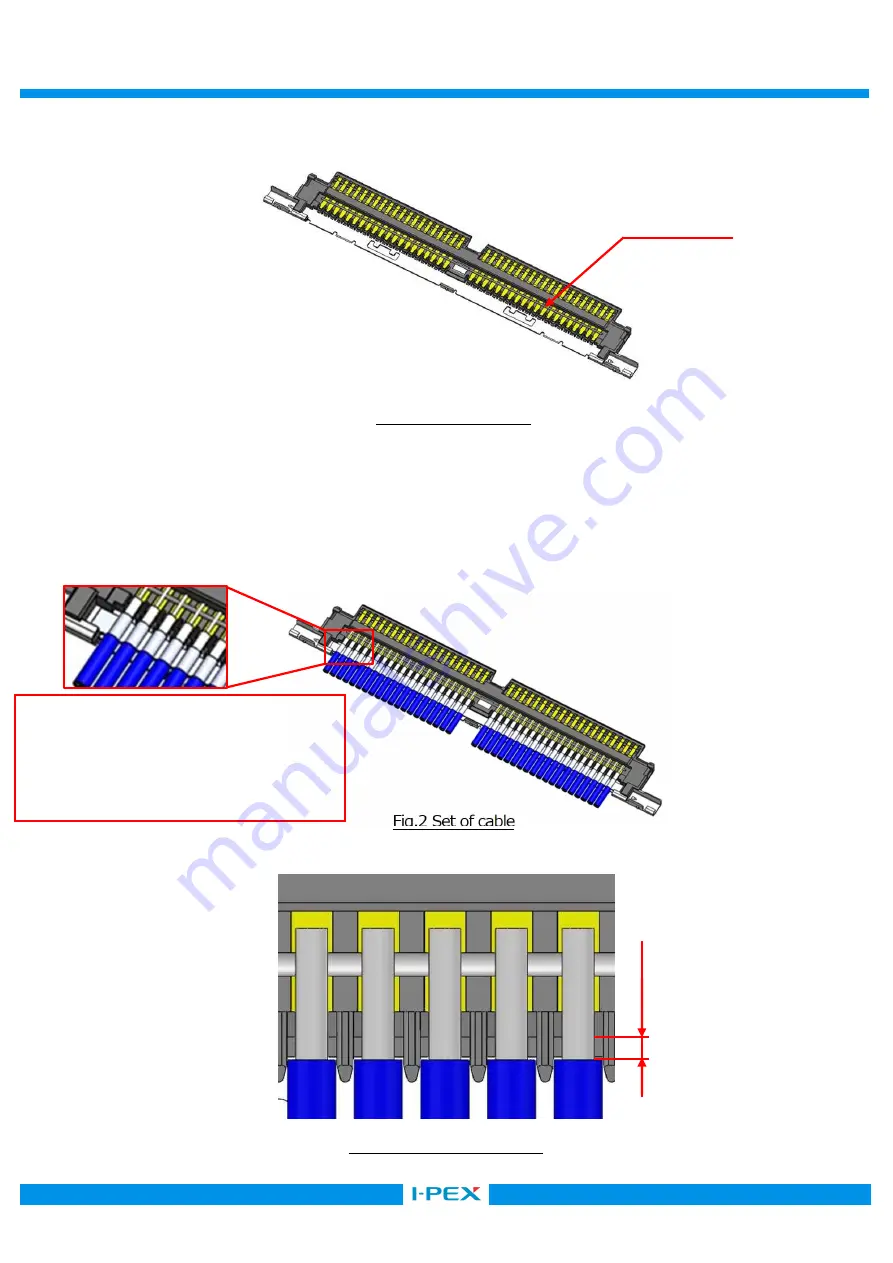

③ コネクタに半田バーをセットする。

Pre-set and locate solder bar at center of connector (HSG ASS’Y).

Fig.1 Set of solder bar

④ ケーブルをセットする。

Set the cable.

※ディスクリートケーブルのセットは芯線と SHELL が接触する恐れがある為、Fig.3 のように 0.25MAX を守ってください。

※Setting discrete cable is to protect 0.25MAX. as Fig.3. There is danger that Center Conductor touch SHELL.

Fig.2 Set of cable

Fig.3 Setting Discrete Cable

Solder Bar

0

.2

5

M

A

X

.

※裏表に注意してください。

GND

バーが下面となります。

※Please pay attention to the front and back sides.

The GND bar is on the bottom.