CABLINE-CX II PLUG With Cover Assembly Manual

Document No.

ASM-17008

3

/

16

Confidential C

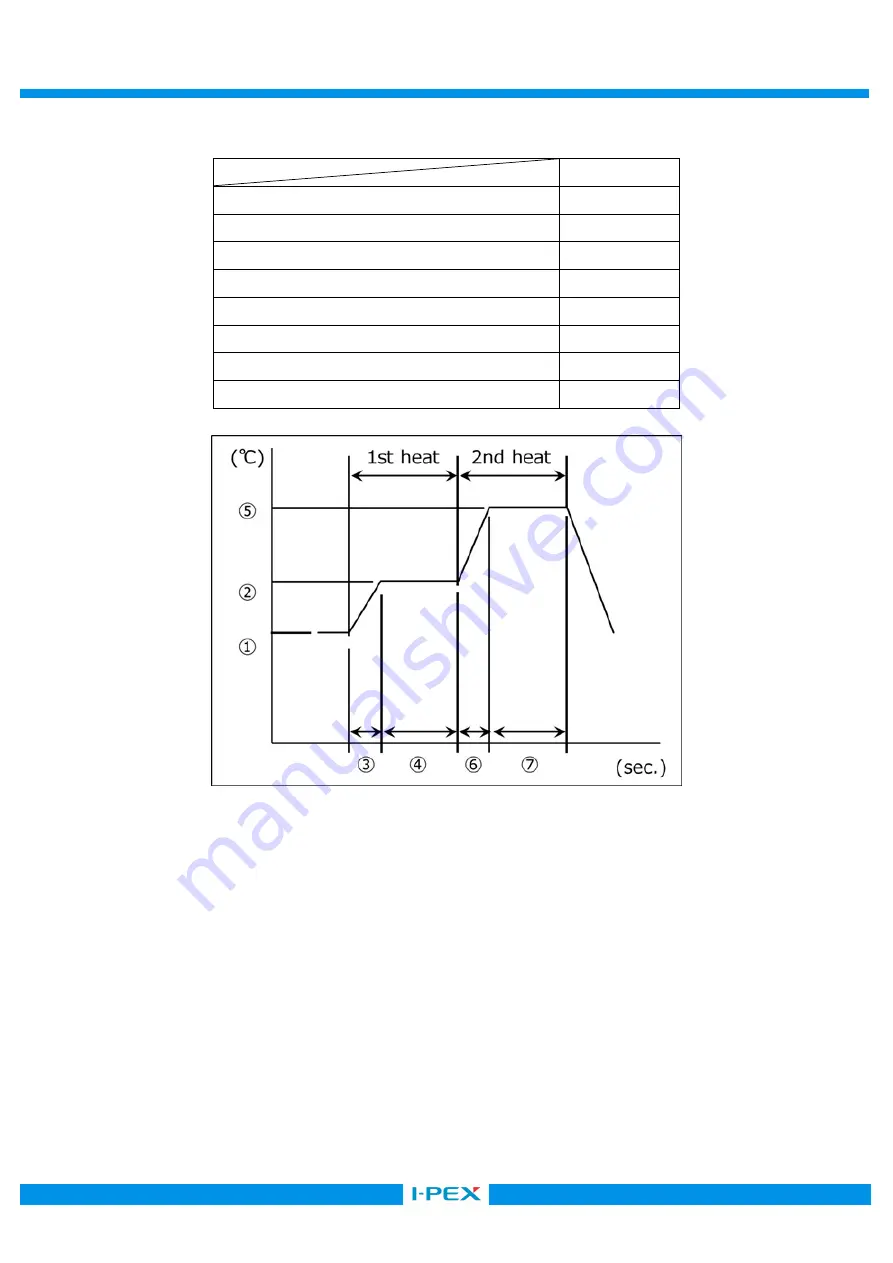

4. パルスヒート条件[推奨] (Recommended pulse heat condition)

Micro-Coax

①アイドリング温度 (Idle temp.)

150℃

②1

st

ヒート設定温度 (1

st

heat temp.)

220℃

③ 〃 立ち上がり時間 ( 〃 rise time)

0.5sec.

④ 〃 維持時間 ( 〃 holding time)

2.0sec.

⑤2

nd

ヒート設定温度 (2

nd

heat temp.)

320℃

⑥ 〃 立ち上がり時間 ( 〃 rise time)

0.5sec.

⑦ 〃 維持時間 ( 〃 holding time)

5.0sec.

ヒーターチップ加圧力(Heater tip Pressure)

11N

※パルスヒート条件の評価は弊社のパルスヒート冶具、装置で確認しております。

パルスヒート冶具形状や装置、環境等の違いにより、最適なパルスヒート条件は変わることが予想されます。

貴社で御使用の際は、充分なパルスヒート条件の検討を行っていただくよう御願い致します。

This pulse heat condition was evaluated and confirmed by our pulse heat jig and instruments.

The most optimum condition may change based on the shapes of pulse heat jig and instruments,

the environments, or other reason.

Therefore, please examine the pulse heat condition adequately in advance of use.