CABLINE-VS II PLUG Assembly Manual

Document No.

ASM-17005

7

/

16

Confidential C

③

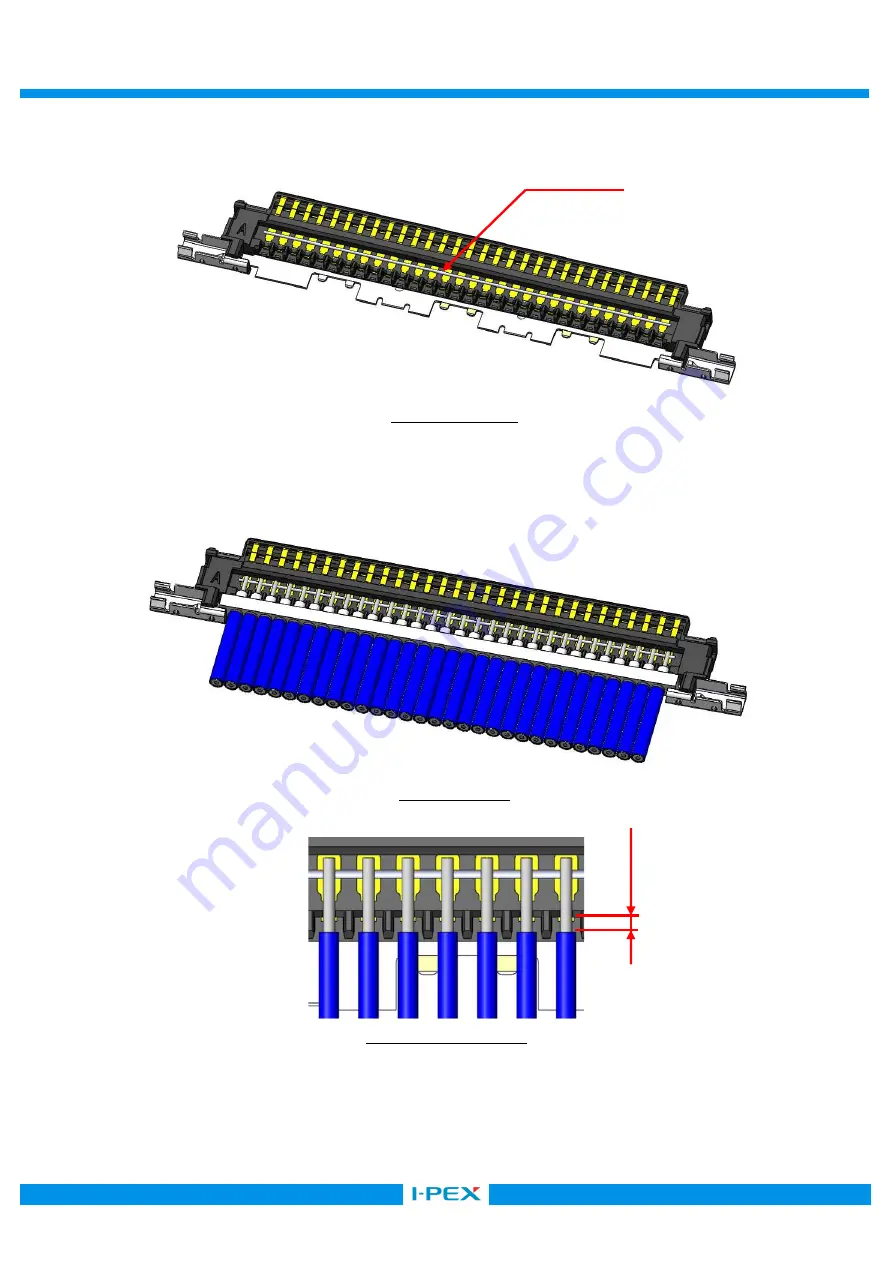

Pre-set and locate solder bar at center of connector (HSG ASS’Y).

Fig.1 Set of solder bar

④

Set the cable.

※

Setting discrete cable is to protect 0.2MAX. as Fig.3. There is danger that Center Conductor touch SHELL.

Fig.2 Set of cable

Fig.3 Setting Discrete Cable

0.

2

M

A

X.

Solder Bar