CABLINE

®

-VS Instruction Manual

Document No.

HIM-08004

3

/

16

Confidential C

1

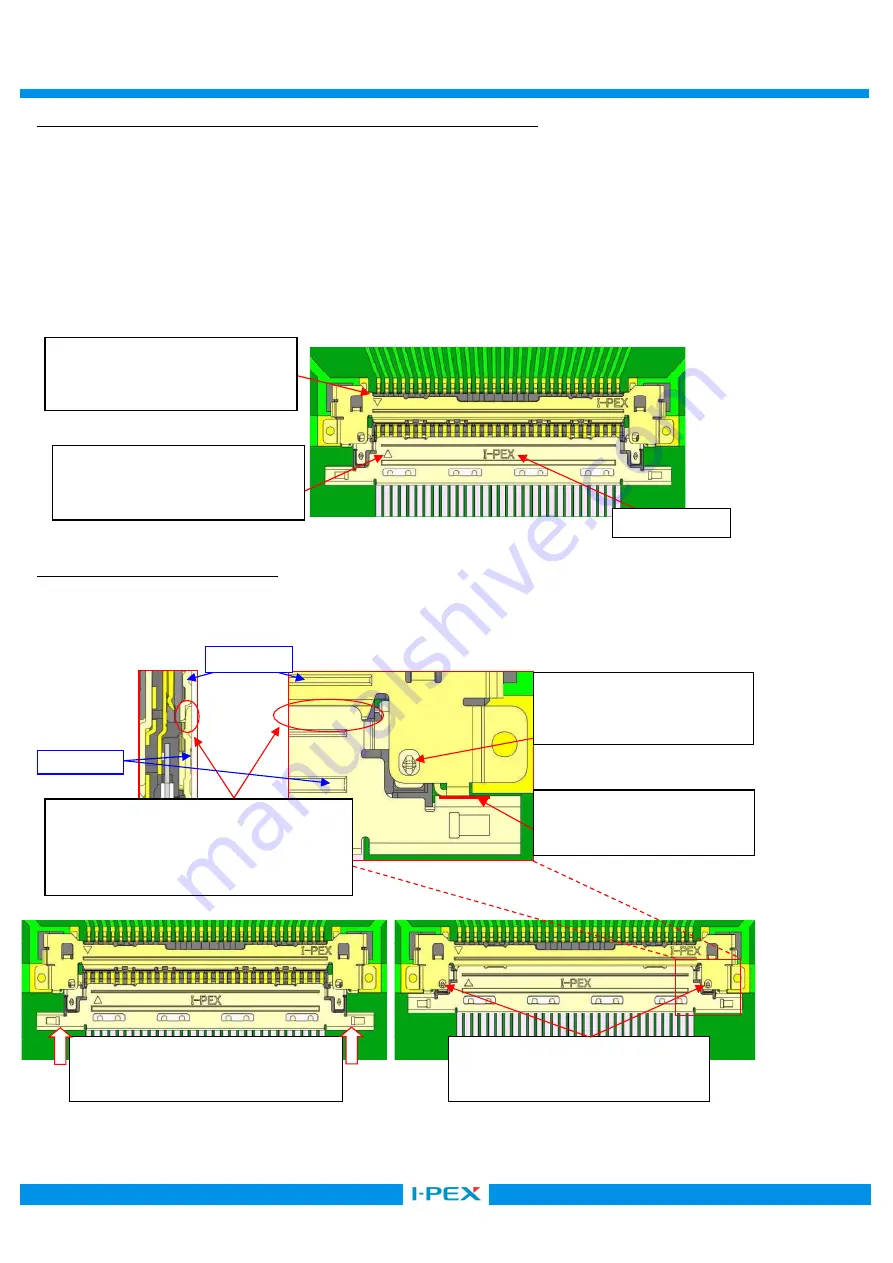

.ケーブル側コネクタのセット方法(

Direction to mate. /

线端连接器设置方法

)

図

1

のように、基板側コネクタの基準

pin

にケーブル側コネクタの基準

pin

がくるように、セットします。

As shown in Fig.1, please set so that the datum pin mark of the cable connector and the PCB connector

are matched.

如图

1

所示,将板端的连接器的基准

Pin

记号与线端的连接器的基准

Pin

记号对齐设置好。

DATUM MARK

無の場合

/ For the connector without DATUM MARK. /

没有基准

Pin

记号的情况

ケーブル側コネクタの

I-PEX

MARK

が上面にくるように、セットします。

Please set so that I-PEX MARK of the cable connector is upper side.

将线端的连接器有“

I-PEX

”的一面向上设置。

図

1

(

Fig.1

)

2

.嵌合方法

(How to mate. /

插入方法

)

図

2

のように、ケーブル側コネクタの両側を水平に押し、ロック穴にロックが掛かると、嵌合完了となります。

As shown in Fig.2, push both ends of cable side connector horizontally until the lock is locked.

如图

2

所示,按压线端连接器的两侧,将连接器水平插入。当

Plug

上锁扣凸点被锁住后,表明已经完

全插入到正确位置。

図

2

(

Fig.2

)

コネクタ両側を水平に押す

Push both ends of connector horizontally.

按压

Plug

的两端,将

Plug

水平插入

ロックが掛かっている事を確認

Check the lock is locked.

确认锁扣凸点有被锁住

ケーブル側コネクタ基準

pin

Datum pin of cable side connector.

线端的连接器的基准

Pin

记号

ロックが掛かっている事を確認

Check the lock is locked.

确认锁扣凸点有被锁住

I-PEX MARK

基板側コネクタ基準

pin

Datum pin of PCB side connector.

板端的连接器的基准

Pin

记号

隙間がないか確認

Confirm whether there is space.

确认此处没有间隙

⇒

Plug shell

と

Rece shell

がオーバーラップ

している事を確認

Check the overlap of Plug shell and Rece shell.

请

确

认

Plug

的

SHELL

与

RECE

的

SHELL

Plug shell

Rece shell