CABLINE-VSF CONN. Instruction Manual

Document No.

HIM-13010

7

/

12

Confidential C

SHELL ASS’Y(LOCK BAR

有り品

)

及び

SHELL(LOCK BAR

無し品

)

共通

/

Common matter by SHELL ASS’Y(With LOCK BAR) and SHELL(Without LOCK BAR).

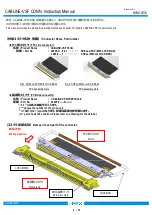

水平方向

Horizontal direction.

本コネクタを安全に使用して頂く為に下写真の様にこじり角を

5

°以下で御願い致します。

仮差しの状態から片側のみを挿入した場合、下図の様にこじり

MAX.

値が

5

°となります。

5

°以下であればコネクタの変形は発生致しません。

To use this connector safely, please keep mating angle to be less than 5°degree as shown in the figure below.

When you push only one side at the temporary insert condition, maximum slanted degree have to be less

than 5°. Deformation of the connector doesn't occur if insertion angle is kept less than 5 degree..

5

°こじり状態

/ 5

°

slanted condition.

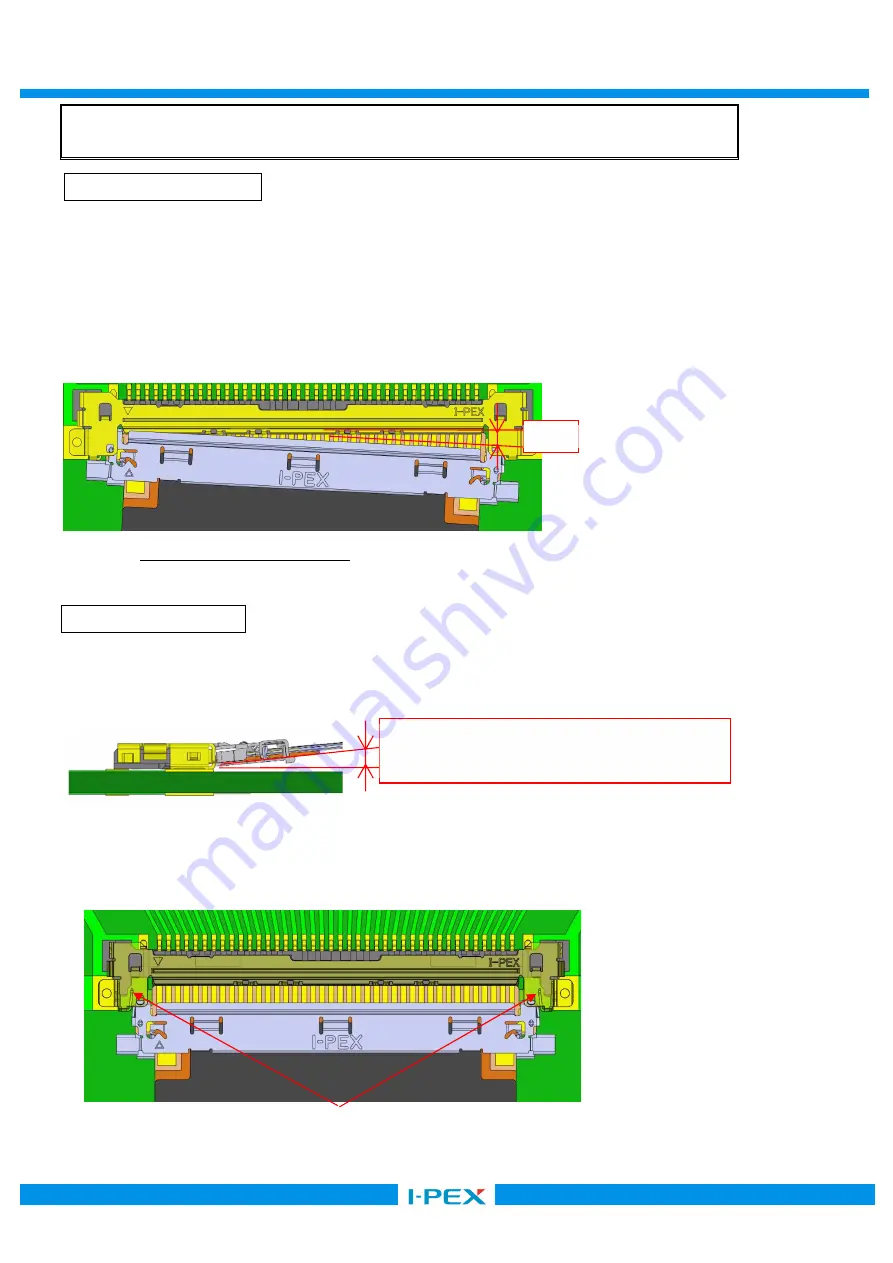

垂直方向

Vertical Direction.

コネクタ挿入開始時の許容角度は下図の通りです。

The acceptable angle for mating is below.

下図のように、

RECE. SHELL

に挿入ガイドが設定されています。

ガイドに沿って挿入を御願い致します。

ガイドに沿って挿入頂ければコネクタの変形は発生致しません。

RECEPTACLE SHELL has an insertion guide as shown in the figure below. Please insert plug along

with guide, then no deformation will occur.

SHELL

裏面のガイド形状

The guide inside of SHELL.

挿入開始時の許容角度

8

°

The acceptable angle to start connector insertion is 8

°

.

5

°