CABLINE-VSF CONN. Instruction Manual

Document No.

HIM-13010

9

/

12

Confidential C

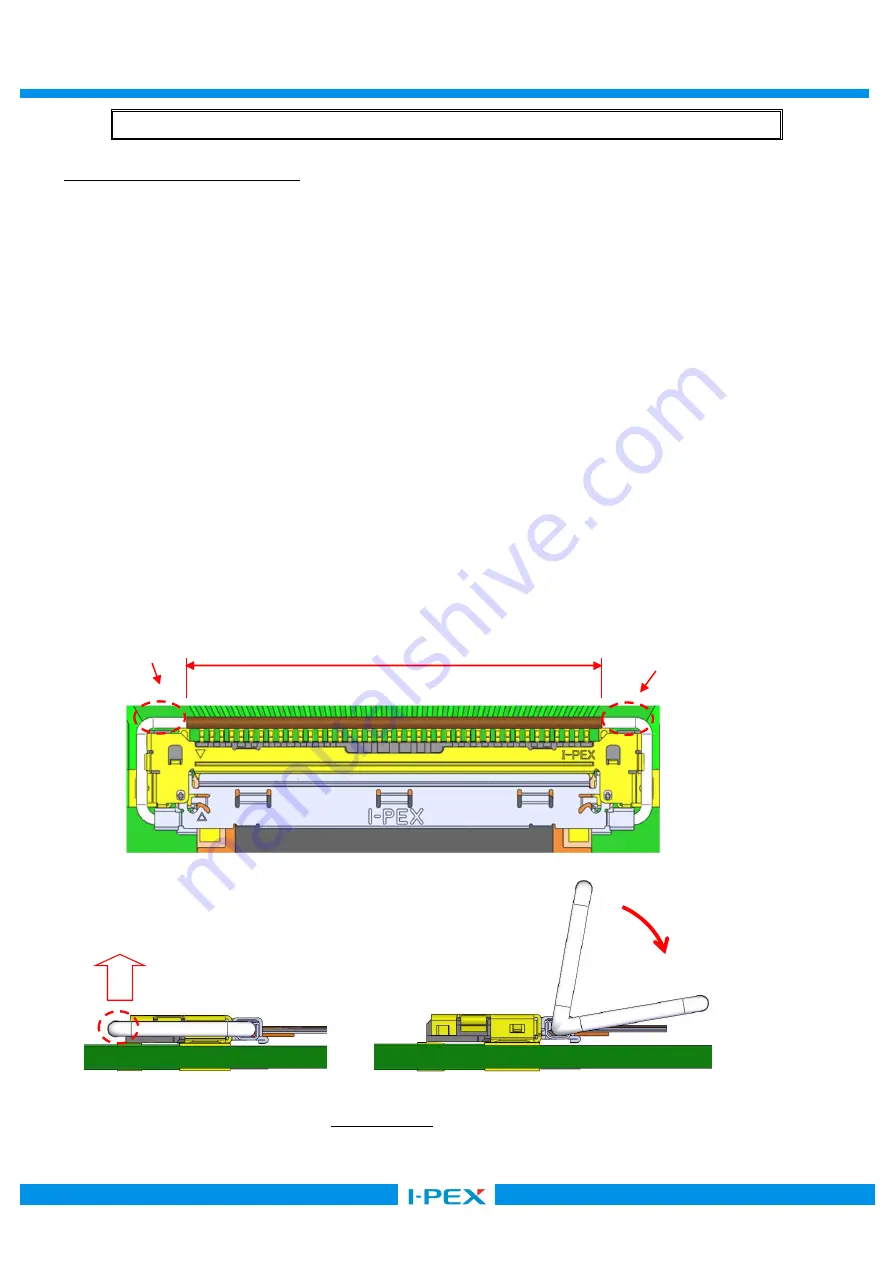

抜去手順Ⅰ

/

Un-mating method

Ⅰ

図

12

の①の箇所のどちらか一方を②の方向に

LOCK BAR

を上げ、基板側コネクタとのロックを解除後、

③の方向に

LOCK BAR

を回転させる。抜去は図

11

と同様の方法にて行う。

注意:

①以外で

LOCK-BAR

を②方向に上げようとすると、

LOCK BAR

が変形したり、コネクタが

破損する恐れがあります。

また、

LOCK BAR

の絶縁コート部を抜去に使用すると、

LOCK BAR

が変形する可能性が

ありますので、抜去には使用しないでください。

なお、絶縁コート部に金属や硬いものを当てると、コートが剥がれてしまう恐れがありますので、

当てないようにご注意願います。

Raise one of

①

points of LOCK BAR in Fig.12 to the

②

direction to release the lock with the PCB side connector, then, turn LOCK BAR

to

③

direction. Un-mating method is same as described in Fig.11.

Caution: Except for

①

part, if you pull up the LOCK-BAR towards direction

②

, LOCK BAR would have

deformation or the connector would have damage. Also, if you use Insulated part of LOCK BAR

for Un-mating, LOCK BAR may deform. Please do not use it for Un-mating. Moreover,

if you hit the metal or hard material onto the insulating part, the coating have possibility to peel off

so that please understand to handle it carefully.

図

12

(

Fig.12

)

SHELL ASS’Y(LOCK BAR

付

)

の場合

/ For the connector SHELL ASS’Y(With LOCK BAR).

③

①

①

②

絶縁コート部

/ Insulated part.