ISH HYBRID CONNECTOR Instruction Manual

Document No.

HDM-0009

7

/

24

Confidential C

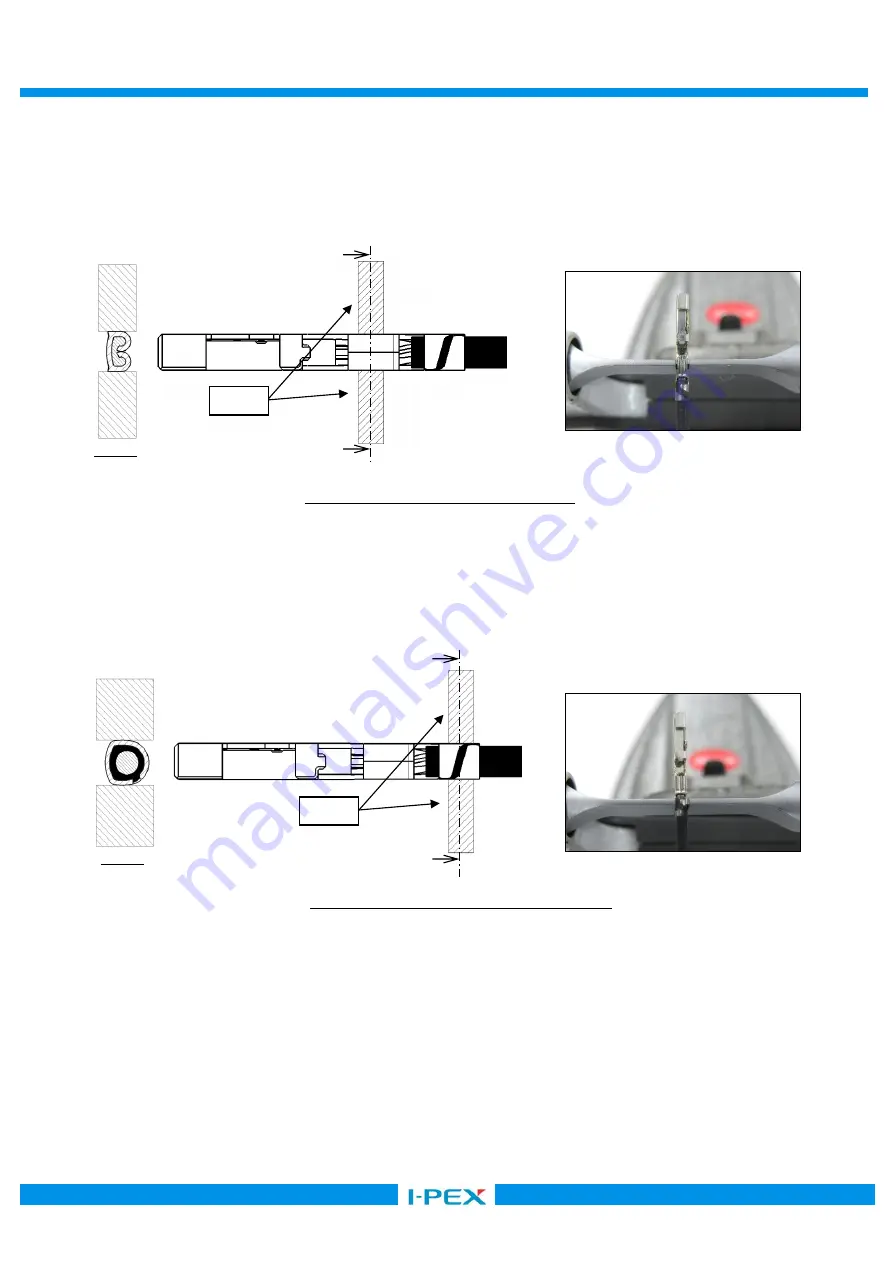

(1)-3. Measuring method for wire barrel crimp width is described below.

To measure the wire barrel crimp width, pinch the side of the wire barrel with a micrometer. (see Fig.7)

Secure terminals firmly to obtain accurate measurement.

Fig 7.

Wire barrel Crimp width measurement

(1)-4. Measuring method for insulation barrel crimp width is described below.

To measure the insulation barrel crimp width, pinch the side of the insulation barrel with a micrometer. (see Fig.8)

Secure terminals firmly to obtain accurate measurement.

Fig 8. Insulation barrel crimp width measurement

Section

Section

Micrometer

Micrometer