NOVASTACK

®

35-HDN Instruction Manual

Document No.

HIM-18019

3

/

8

Confidential C

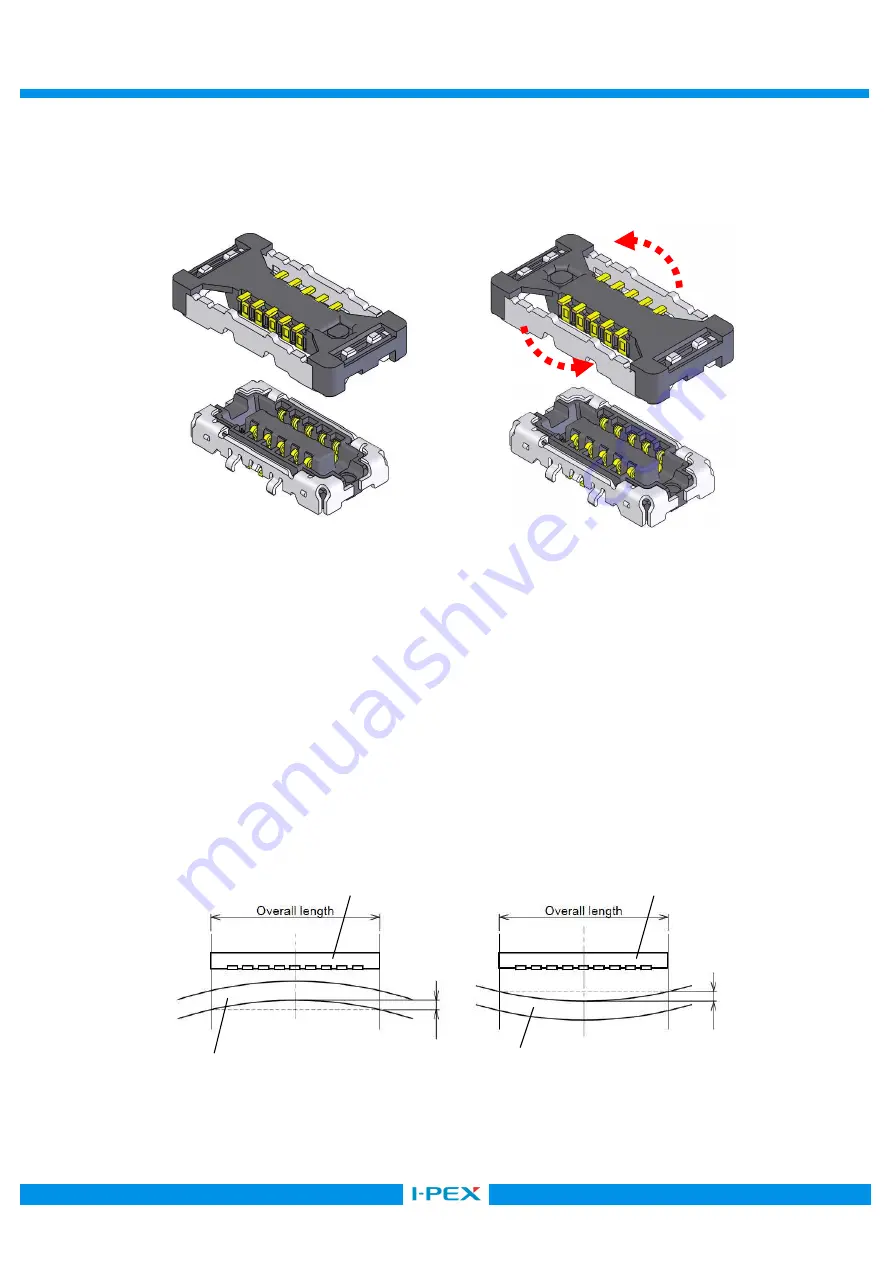

1-3.コネクタの方向性に関して/ Connectors Mating Direction

Plug ass’y 及び Receptacle ass’y 共に方向性はなく、どちらの方向に嵌合しても性能への影響はありません。

The plug and the receptacle can be mated in both ways.

The performance of the connector will not be affected by the mating direction of the connectors.

2.実装に関して/ Mounting

2-1 弊社推奨パターン寸法は弊社製品図面をご参照ください。

The recommended pattern dimensions are shown in the product drawing.

2-2 弊社推奨メタルマスク厚さ・開口率

The recommended metal mask thickness and opening area ratio.

図面 20864 (plug) と 20865 (receptacle) を参照ください。

Refer to the drawing 20864 (plug) and 20865 (receptacle).

2-3. 基板・FPC の反り / Warp of PCB or FPC

コネクタの全長に対して、基板・FPC の反りを 0.02 mm 以下にして下さい。

Please keep the warp of PCB or FPC on 0.02 mm or less for the overall length of the connector.

Max. 0.02 mm

Max. 0.02 mm

Connector

Connector

PCB or FPC

PCB or FPC