16

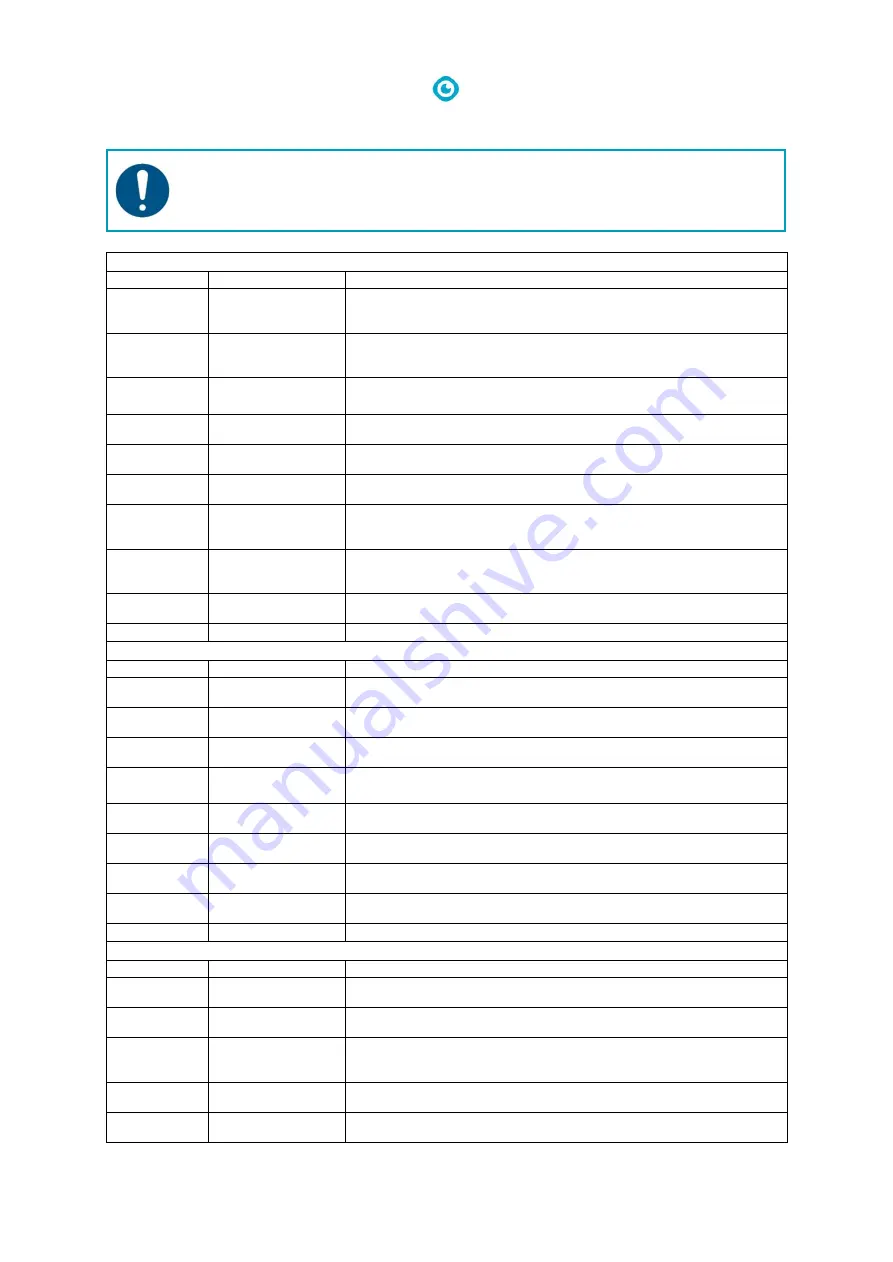

2.1.2

Codes alarm display

ATTENTION

In case an alarm code occurs on the display, please contact service personnel or your

i-team partner.

Alarm summary table control panel

Alarm

Description

Solution

AL_1: Function

Brushes

Ammeter

Brushes ammeter

protection.

Check brushes motor working current. Excessive and continuous working current

detected on the brushes motor.

AL_2: Function

Vacuum

Ammeter

Vacuum ammeter

protection.

Check vacuum motor working current. Excessive and continuous working current

detected on the brushes motor.

AL_3: Function

Power stage Fail

Power circuit damaged.

Brushes or vacuum power circuit damaged: replace the power board. The alarm may

also be displayed if the machine is started when being towed or moving.

AL_4: Function

Overcurrent

Brushes or vacuum

overcurrent.

Short circuit on brushes or vacuum motor detected: check wirings and motors.

AL_5: Function

Overtemperature

Brushes or vacuum

circuit overtemperature.

Brushes and vacuum circuit power stage overtemperature: check if disc brushes run

freely. Measure voltage output.

AL_7: Function

Act2 endsw fail

Squeegee actuator limit

switch reading failure.

Limit switch setting failure. Check connections and squeegee end switch position.

AL_8: Function

Act1 timeout

Brush actuator

movement over the

time limit (12s):

Check connections and any mechanical obstructions.

AL_9: Function

Act2 timeout

Squeegee actuator: end

switch position not

reached.

Squeegee actuator position not reached within the maximum time set. Check actuator

connections and/or any mechanical obstructions.

AL_11: Function

Water Level

Recovery water tank

full.

Empty recovery tank. Check if the recovery tank floating switch works correctly.

“DRIVE” ALARM SUMMARY TABLE

Alarm

Description

Solution

AL_13: Traction

Pedal Failure

Pedal tear.

Check pedal potentiometer wirings.

AL_14: Traction

Release Pedal

Pedal active at power

on.

Moving switch active at power on: release the pedal.

AL_15: Traction

Overtemperature

Traction circuit

overtemperature.

Traction power stage overtemperature: check absorption.

AL_16: Traction

Power stage Fail

Traction circuit

damaged.

Traction circuit damaged: replace the power board. The alarm may also be displayed if

the machine is started when being towed or moving.

AL_17: Traction

Overcurrent

Traction overcurrent.

Short circuit on traction motor detected: check wirings and motors.

AL_18: Traction

Tract. Ammeter

Traction ammeter

protection.

Check traction motor's working current. Traction motor excessive overcurrent

detected.

AL_19: Traction

Motor Voltage

Internal reading

mistake.

If failure persists, replace board.

AL_24: Traction

Batt connection

Battery voltage < 10V.

Recharge batteries. If the batteries have been charged and the alarm occurs, check for

loose connections between battery and electronic board.

“GENERAL” ALARM SUMMARY TABLE

Alarm

Description

Solution

AL_20: General

EEprom Failure

Internal eeprom reading

error.

Replace board.

AL_21: General

Key-off failure

Key-reading failure.

Rebound detected on the key signal: check battery-keyboard-function card

connections.

AL_22: General

Main relay

failure

General relay damaged.

The general relay on the board looks damaged: replace the board. The alarm is

triggered even in the event of a damaged power fuse.

AL_23: General

Overvoltage

Overvoltage.

Function card overvoltage detected. Check battery connections.

AL_25: General

Keyboard fail

Display-function card

communication error.

Check connections between display and function card.