i

6

OIM AI-5X82 V2.1 Page 6 of 6

338, New Sonal Link Service Industrial Premises Co-op Society Ltd,

Building No.2, Link Road, Malad (W), Mumbai - 400064.

Tel: 022-66939916/17/18;

E-mail : sales@itherm.co.in

Website : www.itherm.co.in

Mfgd by: Innovative Instruments & Controls LLP

i

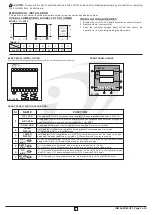

USER GUIDE :

1)

ON-OFF ACTION :

In this mode, output (Relay/SSR) remains ON, till

actual temperature reaches to the set point. On

reaching SP, output turns OFF & remains OFF, till

actual temperature drops down (in heat logic) or

raises (in cool logic) equal to hysterisis set by user.

(As shown in Fig : 3.1 & 3.2)

TEMP (°C)

SP

AMB

O/P

ON

ON

ON

OFF

OFF

TIME

HEAT LOGIC / ON-OFF

Fig: 3.1

HYSTERISIS

TEMP (°C)

SP

AMB

O/P

O/P

ON

ON

ON

OFF

OFF

TIME

HYSTERISIS

COOL LOGIC / ON-OFF

Fig: 3.2

2) TIME PROPORTIONAL ACTION :

In this mode, ON & OFF time of Output (Relay/SSR)

varies proportionally in every cycle (cycle time

settable by User) depending on the deviation of PV

w.r.t SP. This action starts/continues only, when PV

enters or is within the band. (As shown in Fig : 3.3)

TIME

TEMP (°C)

SP

AMB

Fig: 3.3

ON

100%

ON

100%

OFF

100%

OUTPUT

TIME PROPORTIONAL ACTION

ACTIVE ZONE

PROPORTIONAL BAND (P.BAND)

SET BY USER

3) MANUAL RESET (OFFSET ADJUSTMENT) :

In some applications, after adopting Time

Proportionating action, system may stabilize at

particular temperature over a period of time which

can be different than the set value. This steady state

(error) offset can be eliminated by setting this value,

equal and opposite to the existing offset. (As shown

in Fig : 3.4)

TEMP (°C)

SP

AMB

TIME

Fig: 3.4

OFFSET

After offset adjustment

ALARM

LOGIC

If this parameter is set as ‘Direct’, Relay/SSR energizes under Alarm condition &

remains de-energized otherwise. ‘Direct’ setting is generally used for Audio/Visual alarm

output.

If this parameter is set as ‘Reverse’, Relay/SSR de-energizes under Alarm condition &

remains energized otherwise. ‘Reverse’ setting is generally used for tripping the process

under alarm conditions.

ALARM

INHIBIT

If this parameter is set to ‘YES’ & Alarm condition persists, it will disable Alarm O/P at

power ON.

If this parameter is set to ‘NO’ & Alarm condition persists, it will enable Alarm O/P at

power up.

DIRECT

NO

ALARM

ACK.

Once the Alarm is activated, User has following three options to de-activate it. When PV

falls within the programmed limits, the alarm will be de-activated automatically.

Once the alarm is activated, it remains activated until acknowledged manually by UP

key.

Once the alarm is activated, it can be de-activated either by pressing UP key or when

PV falls within the alarm limits.

AUTO

PARA

METER

LOWER

DISPLAY

UPPER

DISPLAY

DESCRIPTION

DEFAULT

NC

: Normally Close terminal of relay

NO

: Normally Open terminal of relay

OP1

: Output 1

OP2

: Output 2

PV

: Process Value (Actual temperature)

C.A.: Control Action

CJC: Cold Junction Compensation

CM : Common terminal of relay

EMI : Electro Magnetic Interference

LWC: Lead Wire (Length) Compensation

SP

: Set Point Value (Set temp.)

SSR

: Solid State Relay

T.P.

: Time Proportional

T/C

: Thermocouple

ABBREVIATION