10. Coordinate System Definition Data Edit W

indow

188

Rtn

nt

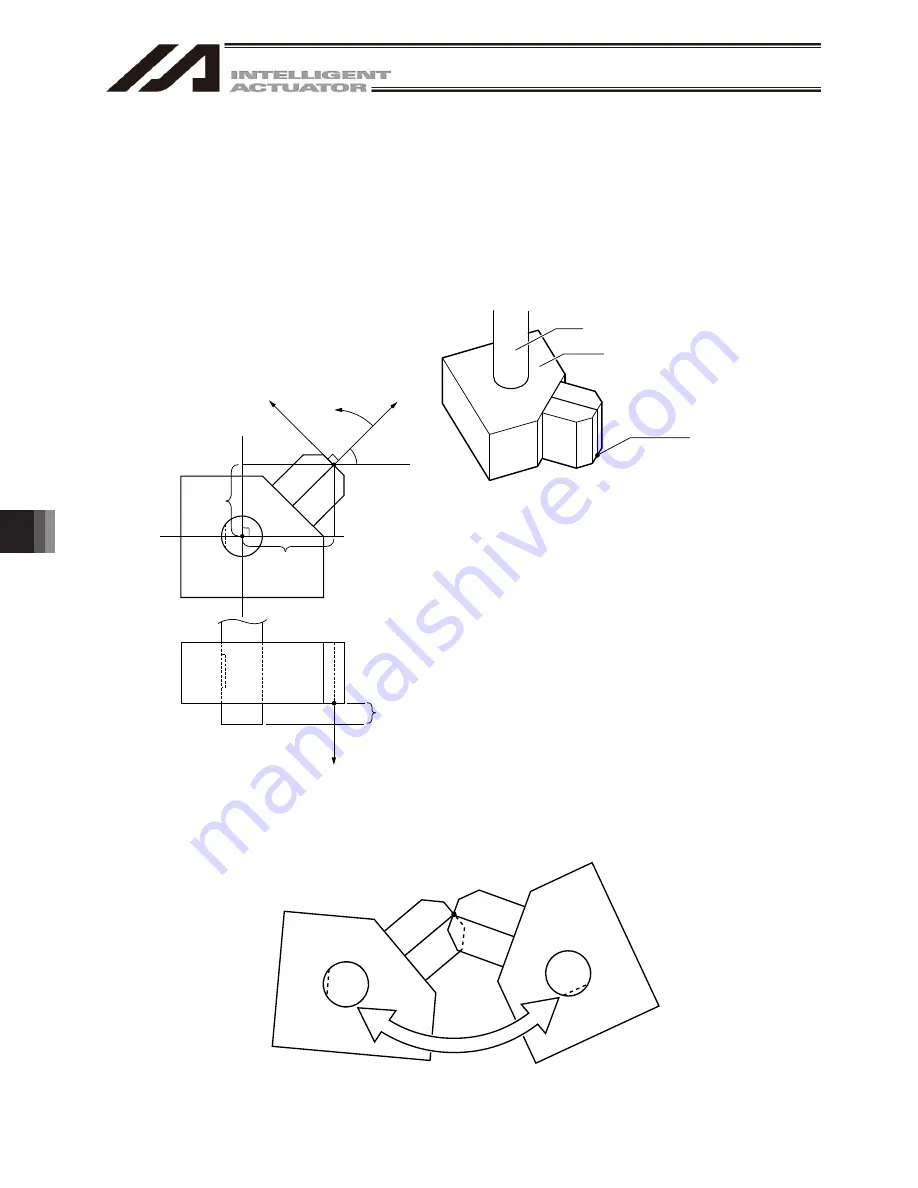

X

nt

Y

Roftn

Xoftn

Yoftn

Zoftn

Ztn

R-axis

Tool

Tool end

Xoftn: X tool coordinate offset

Yoftn: Y tool coordinate offset

Zoftn: Z tool coordinate offset

Roftn: R tool coordinate offset

Xtn: Tool Coordinate system, X-axis

Ytn: Tool Coordinate system, Y-axis

Ztn: Tool Coordinate system, Z-axis

Rtn: Tool Coordinate system, R-axis

(n indicate tool coordinate system No.)

10.3 Tool Coordinate System

A total of 128 different coordinates, provided as a combination of three-dimensional orthogonal

coordinates and rotation axis coordinates, are defined by the dimensions (offsets) of the tool (hand etc.)

installed on the tool installation surface. Note that tool coordinate system No. 0 is reserved in the system

as the tool coordinate system with 0 offsets.

When a defined tool coordinate system No. is selected, the tool end, not the center of the tool installation

surface, is used as the positioning destination.

(Note) For 3-axis type of IXP-3N315 and 3N4515, it is ineffective even if it is set to R-axis.

Select a defined tool coordinate system and jog the R-axis, and the machine will operate as illustrated below:

Summary of Contents for IA-101-X-MW

Page 2: ......

Page 4: ......

Page 8: ......

Page 50: ...1 Before You Begin 42 1 4 Connection to Controller Fig 1 48 X SEL K J Type Controller...

Page 52: ...1 Before You Begin 44 Figure shows example of TT Fig 1 50 Table Top Actuator TT TTA...

Page 53: ...1 Before You Begin 45 Fig 1 51 X SEL KX JX Type Controller...

Page 62: ...1 Before You Begin 54 Fig 1 60 ASEL Type Controller USB Cable...

Page 63: ...1 Before You Begin 55 Fig 1 61 PSEL Type Controller USB Cable...

Page 189: ...9 Symbol Edit Window 181...

Page 251: ...13 How to Reset an Absolute Encoder 243 Fig 13 38 Arm Length 120 Reference Position...

Page 386: ...16 Appendix 378...

Page 391: ......