13. How to Reset an

Absolute Encoder

305

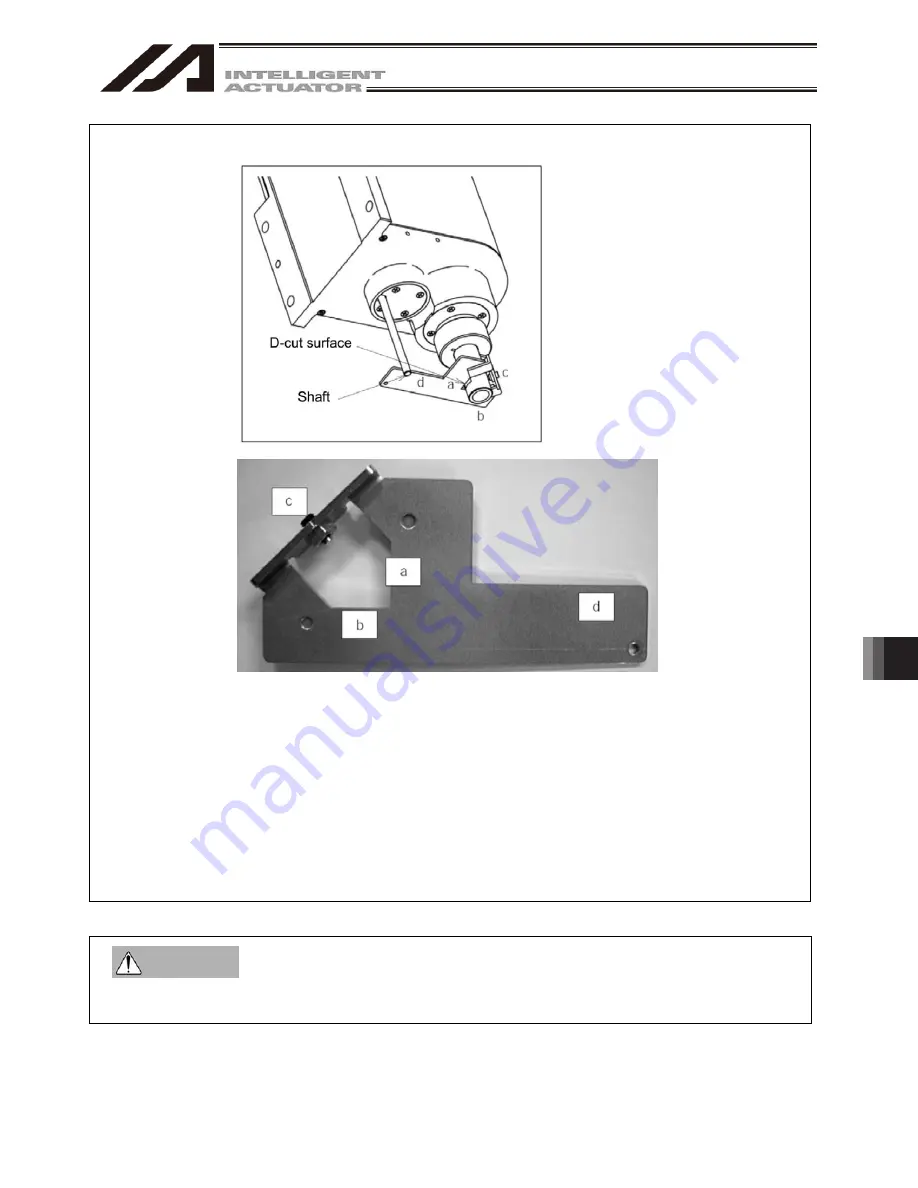

Jig Installation method

[1] Insert the ball-screw spline into the hole in the jig from below.

[2] Cause the D-cut surface of the ball-screw spline to contact the surface a.

[3] Cause the side surface of the ball-screw spline to contact the surface b.

[4] Tighten the screw c to secure the jig onto the ball-screw spline.

* At this time, confirm that the adjustment jig is vertical to the ball-screw spline and that the D-cut

surface and surface a are firmly in contact.

* Applicable screw: Hexagonal socket head setscrew M5

* Tightening torque: 20 [N

cm] (reference)

[5] Insert the supplied shaft into the hole in the ZR unit.

* Exercise caution because the shaft will come off if the hand is released.

[6] Turn the ball-screw spline until the supplied shaft contacts lightly with the surface d of the jig.

Always press the EMERGENCY STOP switch before setting an adjustment jig. Failure to do so may

cause the actuator to malfunction and result in a serious accident.

Warning

Summary of Contents for IA-101-X-MW

Page 2: ......

Page 4: ......

Page 8: ......

Page 50: ...1 Before You Begin 42 1 4 Connection to Controller Fig 1 48 X SEL K J Type Controller...

Page 52: ...1 Before You Begin 44 Figure shows example of TT Fig 1 50 Table Top Actuator TT TTA...

Page 53: ...1 Before You Begin 45 Fig 1 51 X SEL KX JX Type Controller...

Page 62: ...1 Before You Begin 54 Fig 1 60 ASEL Type Controller USB Cable...

Page 63: ...1 Before You Begin 55 Fig 1 61 PSEL Type Controller USB Cable...

Page 189: ...9 Symbol Edit Window 181...

Page 251: ...13 How to Reset an Absolute Encoder 243 Fig 13 38 Arm Length 120 Reference Position...

Page 386: ...16 Appendix 378...

Page 391: ......